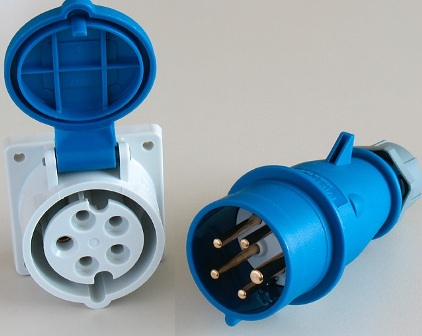

Industrial plug connectors

In industry and construction, plug-in connectors are used, the operational requirements of which are increasing. These connectors should be more reliable and secure than conventional plugs and sockets. In general, industrial plugs must meet the following criteria:

-

Eliminate the possibility of accidental shutdown, which can lead to an accident;

-

They are protected from dust, moisture, aggressive environment;

-

Special connectors are adapted for explosive and fire-hazardous conditions;

-

Special connectors for use in high humidity conditions;

-

Connectors differ in different rated voltages, currents, number of phases;

-

Some industrial connectors can be used in everyday life, for example to connect diesel generators.

International standard IEC 60309 of the International Electrotechnical Commission regulates the parameters of plugs, sockets and connectors used in industry. The highest allowable voltage from the standard is 690 volts at DC or AC. The highest current is 125 amps. The highest frequency is 500 hertz. Operating temperature range — from -25 ° C to + 40 ° C.

There are many sockets and plugs that differ in size, number of pins connected to current and number of phases supplied. Connections have a minimum degree of protection of the housing IP44 (often higher), which allows them to be used outdoors. Along with the ability to transmit large currents, industrial connectors prevent the possibility of accidentally connecting household appliances to sockets that are not intended for them, the shape of the plug simply will not work.

Plugs and sockets are color coded to indicate the voltages and frequency ranges used in a particular network. For example:

-

Yellow indicates a range of 100 to 130 volts at a frequency of 50 to 60 Hz;

-

Blue indicates the 200 to 250 volt range at 50 to 60 Hz;

-

Red indicates the range of 400 to 480 volts at a frequency of 50 to 60 Hz;

The color code refers to the highest voltage between phases.

Most often, the blue connectors serve as weatherproof external contacts for connecting external devices. Yellow - for 110 volts of transformer power, for example on construction sites in the UK, this solution is used to protect workers from electric shock when using power tools on an outdoor construction site.

Typically, the large 32 amp blue plugs provide power to structures such as cabins, while mobile trailers power the small 16 amp blue plugs. The red three-phase sockets supply power to portable three-phase equipment.

According to the IEC 60309 standard, sockets and plugs with different voltages have a different color and most often you can find:

-

Yellow — for voltage 125 volts;

-

Blue — for voltage 250 volts;

-

Red — for voltage 400 volts;

-

Black - for a voltage of 500 volts, they can be found on ships.

According to the IEC 60309-2 standard, connectors come in several variants, designed so that a plug of one specific type can only be connected to a specific type of jack. The diameter of the ring body is different for currents of 16, 32, 63 and 125 amperes. Frequency and voltage combinations differ in the location of the keyway mass.

The first terminal can be located in one of 12 positions spaced at 30° on the circle on which the pins are mounted. The position is determined by the socket, for example, the key is located at 6 o'clock, that is, just below and coincides with the key of the plug. The first pin has a larger diameter than all the others, in any case, to rule out the wrong type of plug connection.

Optionally, the 63 and 125 amp connectors can be equipped with a 6mm pilot contact which engages after the other pins of the plug engage, and when disengaged, it is the first to open. This is to ensure that when the plug is disconnected, in the event of a claim, neither the plug nor the outlet will be damaged and the person will not be injured.

The pilot contact is located in the center of the contact circle of the 4 or 5 pin connector. If the connector is three-pin, then the control pin is located on the contact circle directly opposite the ground contact, while the other pins are placed at an angle of 105 ° on either side of it.

The most common types of connectors are:

-

yellow (110/120 volts) 2 phase + ground;

-

blue (230/240 volts) 2 phases + ground;

-

yellow (110/120 volts) 3 phase + ground;

-

blue (230/240 volts) 3 phases + ground;

-

red (400 volts) 3 phases + neutral + ground.

Red, three phases + neutral + ground

This connection allows connection to a three-phase 400-volt network, at rated currents of 16, 32, 63, 125 or even 200 amperes. They are widely used on construction sites in Central Europe, where three-phase equipment and one phase at 230 volts are used for other devices.

So-called power splitters allow you to get three groups of one phase from such a connector for individual connection to balance phase loads, which is very important for generators. Such configurations are often used at exhibitions, festivals, large events.

Five prongs are arranged in a circle, and the grounding prong is thicker and longer than the mains. Looking at the output, the phase sequence is clockwise L1, L2, L3. Because some wires can be designed for reverse motors, the pins on some building and industrial plugs can be interchanged to reverse the phase sequence.

Three-phase motors that do not require a neutral use four-pin connectors that have only three phases and ground and no neutral.

Blue, single phase + neutral + ground

Single phase connection. In particular, the smallest, at 16 amps, is particularly common in mobile homes, as well as parks and marinas in Europe. Trailer sockets have been almost entirely replaced by those replacing other 230 volt plug and socket standards. This is due to the safety of connections due to the high degree of protection of the shell of such a connection. In small temporary buildings and structures, especially with electric heating, 32 amp connections are used.

Not all single-phase electrical installations are critical about the location of the phase and neutral, and quite often there are contacts installed backwards. If compliance with the position of the phase and zero is critical for the device, then devices equipped with an RCD should be used.

When you install such sockets with the connector down, using them outdoors is very convenient in all weather conditions. For this reason this connector has now become the standard for lighting equipment (up to 16A) in the UK film and television industry. Often these outputs serve as outputs for three separate phases of a larger three-phase power supply.

Blue, three phases + neutral + ground

These plugs and sockets serve both 110 and 240 volt power systems. They are popular for connecting outdoor lighting, in the audio industry as a replacement for NEMA connectors. Often three wires are used for separate power supply or combined.

When choosing between 110-120 volts or 220-240 volts between phase and neutral, or between phase and phase, these connectors are also useful. If three phases are not required and mode selection is not required, then there are yellow-orange connectors to supply single-phase 110-120 or 220-240 volts to the load.