Cable lugs and their use, lug crimping

The use of cable lugs and bushings greatly increases the efficiency of the installer and facilitates the process of making cable connections. Cable lugs and bushings are used to terminate cables and wires to fix them securely together, as well as in clamps for screws and springs.

Aluminum, aluminum-copper and copper lugs and sleeves allow you to create safe and reliable connections between power sources and consumers, as well as to connect electrical installations.

The tips are universal, and today the industry produces a wide range of them, from which each installer can choose the best option of the desired type to solve his problems, to carry out certain electrical work.

During production, the cables and lugs are marked so that the installer can easily select a lug for the correct cross-section. When the dimensions are chosen as correctly as possible, the connection will be as reliable and efficient as possible.It is important that the mounting surface is clean, then the contact will be the best and the contact pressure will contribute to this.

Types of tips

There are lugs of different types, for use with cables of different cross-sections and purposes, for connection to terminals of all designs and modifications.

Meanwhile, the following types of fittings are most popular: tubular aluminum, copper and steel, heat shrinkable, bushings non-insulated and insulated, insulated and non-insulated ring, forks and pins, double tubular and counter angle and clamping bolt fittings.

Crimp tips provide the most efficient installation, simply select a tip for the desired section, place the tip on the wire and compress it with a special tool.

Copper ears

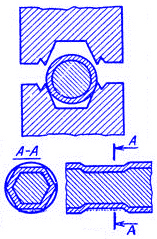

For working with copper wires, copper tips made of tightly drawn copper tubes are used. On one side of the tip is a clamping piece—a flattened contact blade with a hole in it. On the other side there is a tube opening for the wire.

The field of application of such advice is the installation of electrical appliances, the implementation of grounding, the connection of input-distribution devices in residential and communal services. These tips are also used in industry where a wide variety of equipment is connected to them. Copper ears are available in tinned and untinned versions. Canned food is protected from oxidation by an additional tin coating.

Aluminum lugs

For the installation of aluminum wires, aluminum lugs are used, which, like copper, are made of seamless pipes. On one side the tip has a contact blade (flattened part of the tube) with a hole, on the tail side - a tube hole for the wire.Aluminum wires are connected to the tip by pressing with a special tool. The aluminum tip is pre-lubricated with quartz-vaseline grease to prevent oxidation.

Aluminum-copper lugs

Most often, switchgears have exactly copper busbars, therefore there are aluminum-copper terminals, the contact blade of which is made of copper, and the landing tube is made of aluminum. Such terminals are made by friction diffusion (friction welding) or by cold gas dynamic spraying, where the contact blade is aluminum but has a copper splash on top to ensure stable contact.

Bolts

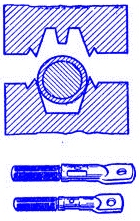

When traditional pipe lugs are crimped with a special tool or attached by soldering, lug bolts are fixed with a clamping bolt. The clamping bolt is part of the tip and no tool crimping is required.

It is enough to fix the core in the bit with a bolt until it stops, after tightening the bolt, its head will break off. This will achieve a reliable connection between the wire and the tip and the fixation will become irreversible. Tightening is done with a wrench, and the cross-section of the connecting wire can be significantly smaller than the maximum possible for the tubular part of the ear — this is the advantage of bolted ears.

Crimping tools

To create a reliable electrical connection without soldering, crimping pliers are used. With their help, you can connect both the ear and the sleeve to the aluminum or copper cable, which is often required when wiring, when installing electrical equipment, when doing grounding, etc.

Depending on the size of the tip and the complexity of the work, different types of crimping pliers are used. There are manual crimping pliers for the installation of low-current systems with cable cross-sections from 0.25 to 16 sq. mm.

In large industries, for example, when installing substations or when it comes to installing high-current systems, say, power wires for power from a car battery, it is more convenient to press the wires with a hydraulic press, for which the cross section up to 120-240 sq. Mm will not be a problem at all.

Obviously, if a bolt bit is used, a key is sufficient. So in each case the crimping tool is used differently.

If it is necessary to crimp terminals with colored cuffs for stranded wires, then there are special color-coded crimpers for this purpose.

Direct crimping

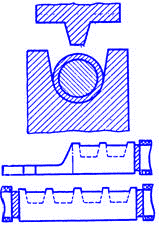

Pressing (crimping) is done in different ways: local indentation, continuous compression or combined compression. The vein is inserted into the tail tube portion of the tip or into the sleeve, then compressed by punching the die. The high pressure generated during the crimping process creates good contact and a reliable electrical connection between the wire and the tip.

When the teeth of the punch are pressed at one or more points on the tip, the best contact is made where the pressure is greatest. Such pressing is called local indentation pressing.

If a lot of pressure is created along the entire length of the clamped part of the tip, the reduction is called continuous. With continuous crimping, full electrical contact is achieved along the entire length of the crimped portion of the wire.

Compound compression is used to improve the contact between the tube portion of the tip and the core. With combined reduction, the electrical contact is improved even more, because here, under conditions of continuous reduction, additional pressure is created at the point of indentation of the tooth.

In all three cases, the contact is obtained with a sufficiently high quality if the field of application is correctly determined by the installer, if the tool is selected correctly, if a suitable tip is selected, if the surfaces are cleaned and the crimping is done correctly.