Perforated cable ducts and their use

To reduce costs, simplify installation and reduce the weight of cable routes, electrical boxes in the form of perforated cable channels are used. Such channels are distinguished by a special profile of the vertical sides — in the form of a comb. When the requirements for IP (up to the degree of protection of the shell) and the appearance of the structure is not particularly high, then precisely perforated cable channels are used.

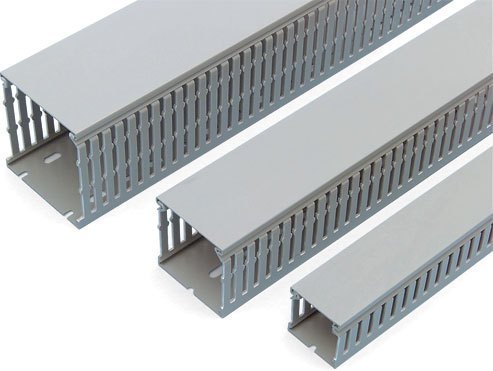

What is? A U-shaped two-meter profile of the required section, which can be finished with a cover, perforated like the profile or non-perforated. The cover is very easy to place on the cable channel when the cable routing is finished. The degree of protection of the perforated cable duct closed with a cover is IP20, and if there is no cover — IP00. The material is PVC, which is non-flammable, or in the simplest case, PVC, which is flammable.

Input distribution devices, control panels and switchboards - also need high-quality assembly accessories so that their operation is durable and reliable, and it is desirable that the installation is quick. This is facilitated by the use of perforated cable channels. Correctly laid wires can be seen immediately, and the operating organization, even in the face of a layman, will easily appreciate what we can say about the acceptance of the equipment ...

Cable channels of this type will allow you to quickly and accurately fix the wires in the cabinet, on the door or inside the switchboard: if the door has buttons, indicators, switches, then the cable channels can be glued to the door.

The side channel punch feature allows you to carry individual wires through the channel without drilling or cutting anything; you just need to pass the wire through the slot or in extreme cases tear off the petal. The wiring process becomes simple and impossible.

Perforated cable ducts are available in rectangular and circular cross-sections. The channels of small dimensions are produced immediately ready for easy installation inside the distribution board or on the door: a double-sided tape is fixed at the base of the cable channel - so that the channel can be fixed quickly and firmly, having previously degreased the mounting surface of the distribution board .

Large cable channels have special mounting holes on the base in one or more rows so that they can be fixed with screws, bolts or screws.

Such cable channels are made of PVC, so they are flexible enough and do not crack during the installation process, but if you need to tear off the petal from the side perforated part, it will be easy, because the width of the petals is specially selected, so that, if necessary, you can break off the petals manually without using additional tools.

Not all cabinets are operated under ideal conditions. For the installation of, for example, outdoor cabinets in the northern regions, special perforated cable ducts made of special materials that withstand freezing and do not crack are required. This requires a frost-resistant, halogen-free plastic such as polyamide or polyphenylene oxide.

In low temperature conditions, ordinary PVC becomes very brittle, and the normal stress of installation will cause cracking with the onset of freezing. Polyamide and polyphenylene oxide (PPO), on the other hand, are able to withstand mechanical work load and do not lose their plasticity even when freezing at temperatures below -20 ° C. This is the main advantage of perforated cable channels made of halogen-free plastics, which are also available in different sections.

The size of the cable channel, as well as its shape, are selected based on how many wires and what section will be laid in it. If three to four thin wires are assumed, then a small circular or rectangular cable duct will be suitable. In general, the total dimensions of cable channels (section) reach 125 mm, for example 125×50.Large cable ducts are suitable for panel mounting in main switchboards and in switchgear where they are attached to racks.

It is a mistake to assume that when laying wires in a cable channel, it is plugged with wires tightly and closed with a cover. In fact, it is recommended to fill the cross-section of the cable channel with wires at most half, leaving a margin.

What is it for? The cable channel must withstand 100% mechanical stress, in addition, it is more convenient to install it when there is a place to turn. That is why the cross-section of the perforated cable channel is always taken with a margin.