Requirements for the installation of electrical conductors on trays

Assign trays

Trays are used for laying power and lighting electrical wires made with unprotected wires and unarmored cables with rubber and plastic insulation. Wires with a cross-section of less than 120 mm2 and cables with a cross-section of up to 16 mm2 must be laid on trays.

Perforated trays are used to carry out the main sections of nets, risers, bridges, branches and descents from the routes of the main tray.

Placing trays

Trays are located at a height of at least 2 m from the floor or service platform. In electrical rooms, as well as in rooms served by specially trained personnel, the height of the trays is not standardized.

Bends, intersections, transitions of trays from one width to another and from one brand to another are carried out using perforated assembly tapes purchased in workshops.

When crossing pipelines, the trays are installed so that the distance from the pipelines to the nearest cable or wire is at least 50 mm (pipelines with flammable liquids and gases — at least 100 mm).

When trays are arranged in parallel, the distance from the wires and cables laid in them to the pipelines must be at least 100 mm (to pipelines with flammable liquids and gases — at least 250 mm).

When trays pass hot pipes or when paralleling trays and hot pipes, cables and wires must be protected from heat. Trays can be installed vertically or horizontally. With horizontal arrangement, it is allowed to install trays on several levels.

Trays are installed both near the walls and on prefabricated cable structures (racks, shelves, hangers), as well as on shelves and structures from mounting perforated profiles and strips purchased in workshops.

Perforated trays are placed on the bases, shelves and hangers, they are connected several in a row so that they stick to each other with sides and form a wide perforated plane.

Connecting trays

The connection of the sections and the fastening of the perforated trays to the foundations and shelves of the building is carried out using the supplied complete connecting angles and bolts. Sections of welded trays are connected by bolts and connection plates, which also ensure continuity of the electrical circuit.

To create a reliable electrical contact at the junction of the elements of the trays, grounding washers with sharp projections are installed directly to the painted surface.

The connection of straight sections of perforated trays in one plane is carried out using special connectors in the form of channels, welded trays — by inserting one section into another by 135 mm and fixing with standard fasteners.

When changing the track width of welded trays, transition connectors are used. When moving the track of trays from one level to another at an angle of up to 90 °, as well as when changing the direction of the track, hinge connectors and corner sections are used.

Turns, branches, bypassing ledges and obstacles, intersections, transitions of trays from one width to another and from one brand to another are carried out using special factory-made sections or are carried out according to standard designs.

Fixing trays

The distances between the points of attachment of the trays on the bases and between the supporting structures of the trays must be at least 2 m. To each other.

The supporting structures for the trays are fixed with dowels-nails and dowels-screws, hammered with a construction-assembly gun, as well as with the help of packing and clamping structures or welding.

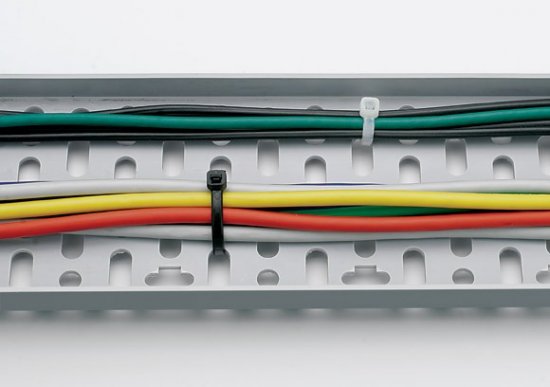

Welded trays are attached to the shelves with special full brackets. Cable ties are also used to mount trays in sections.

It is forbidden to fix blocks, slings and other lifting devices on the installed trays.

Installation of electrical wires

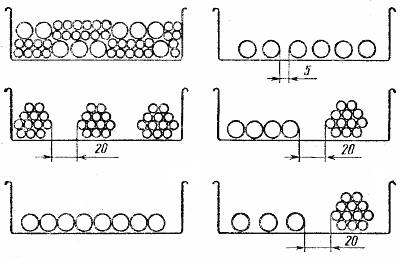

Prepared electrical wiring is delivered to the installation area of inventory cassettes. As a rule, wires and cables should be placed in one row on the trays. It is allowed to place them without a gap, as well as in bundles close to each other in 2-3 layers (in a bundle) and exceptionally in more than 3 layers.

The outer diameter of the bundle must not exceed 100 mm and must not contain more than 12 conductors and up to 3 four-wire cables. The methods of laying wires and cables on steel trays are shown in the figure.

Methods of fastening wires and cables to steel trays

Basically, when laying cables and wires, two methods are used: stretching along the trays on rollers or gutters, and then transferring them to the trays using a special set of mechanisms and devices.

Attaching wires and cables to trays. Bundles of wires and cables placed on trays are secured with bandages. The distance between the strips on the horizontal straight sections of the track should not exceed 4.5 m, and on the vertical sections - more than 1 m.

It is not necessary to fasten cables and wires placed on straight sections of the track when the trays are installed horizontally. If the trays are located flat on supporting surfaces or vertically, then the cables and wires are fixed at intervals of no more than 1 m.

In addition, separate wires, cables, as well as bundles are fixed in bends and in places of branches for all methods of mounting trays at a distance of no more than 0.5 m before and after a bend or branch.

To fasten both individual wires and cables, as well as bundles to trays, tapes and buttons, tapes and buckles are used.

The fastening of unprotected wires and cables with a metal sheath with metal clamps or strips should be done with gaskets made of elastic insulating materials.

In places where they exit from tap holes, wires and cables should be protected from damage by the sharp edges of trays with bushings or wrapped with adhesive insulating tape.

Marking

Wires and cables placed on trays are marked at the beginning and end of the trays, at the points of branches and turns of the track, as well as at the points of connection to electrical equipment.