Installation of electrical machines and devices

General concepts for performing electrical work on machines and devices

Electrical installations are devices that generate, convert, distribute and consume electrical energy. For reliable and trouble-free operation, any electrical installation must be properly designed, equipped with the correct electrical equipment and electrical materials. Installation of all objects must be done carefully.

The requirements for electrical installations are specified in Rules for Electrical Installation (PUE), the implementation of which is mandatory during their design and installation.

Installation of electrical machines and devices is a very responsible, complex and time-consuming process that requires careful preliminary preparation. In addition to the correct and high-quality execution of the installation from a purely technical point of view, requirements are imposed on the installation works in terms of the terms and costs of their implementation.

The installation of large electrical machines is usually associated with the commissioning of new energy facilities or the commissioning of large industrial enterprises on time. Thus, fast and quality installation methods are of great importance.

Before starting the installation, the necessary organizational and technical measures must be taken:

-

preparation of a work project for the organization of work, which must indicate the technological process and schedule for performing all operations;

-

detailed development of the installation process and its implementation at the workplace;

-

correct placement of work and application of maximum mechanization of installation works;

-

ensuring work safety, as well as organizing heating, lighting and ventilation;

-

ensuring the continuous implementation of installation works through the timely and complete supply of tools and materials.

Electrical installations are subdivided into installations with a nominal voltage of up to 1000 V, including electrical installations with a voltage higher than 1000 V.

Installations that are fully or partially energized or that can be energized at any time by switching on the switchgear are considered to be in service.

Outdoor or outdoors are electrical installations that are outdoors. Indoor or closed are electrical installations located in the room. Installations protected only by sheds, mesh fences, etc. are considered outdoor installations.

Requirements for the installation of electrical installations depend on the nature of the premises in which they are installed (see — Classification of premises according to environmental conditions).

Tools and devices used in the installation of electrical machinery

When installing electrical machines (motors and generators) a number of special tools and devices are used.

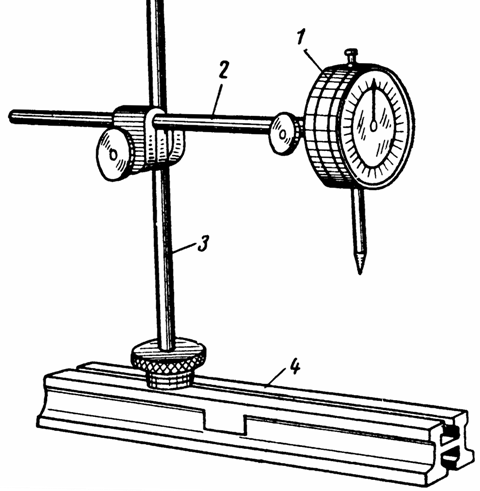

Dial indicators are used to check the shocks of rotating parts (manifolds, shafts, rotors). They consist of a system of interlocking levers or gears that magnify small movements and allow them to be counted on a dial with an arrow.

Indicator

Indicator 1 is mounted on a holder 2 and a vertical pole 3 mounted on a pedestal 4, which allows it to be mounted at any angle. The indicator can also be used to align the alignment of the shafts of electrical machines.

Indicators are produced with a graduation of 0.01 mm. In the measurement, the pedestal is placed on a fixed support, and the measuring rod is installed perpendicular to the axis of the shaft and brought into contact with the surface to be tested. Before counting the leakage value, make sure that the indicator is properly installed. To do this, lightly tap the body of the indicator while the arrow will oscillate. If after flickering it returns to its previous position, then the indicator is installed correctly.

Use to measure the vibrations of electrical machines vibrometers… There are many types of vibrometers, but the installation usually uses the simplest watch-type vibrometers. Before measuring, the device is placed on a vibrating surface.

When installing large electrical machines, it is necessary to align the base horizontally. For this, special devices are used - hydrostatic levels or spirit levels.

In addition to those listed, various types of lifting devices are used during installation. Jacks are used to lift loads to low heights. According to the principle of operation, there are three types of jacks: rack, screw and hydraulic. The lifting capacity of the screw jacks reaches 20 tons. The lifting of very large loads is carried out with hydraulic jacks, the lifting capacity of which is 750 tons.

See also: Mechanisms and accessories for lifting, transporting and rigging during electrical installation

Installation of electrical machines

We will consider the features of the installation of electric machines using the example of an asynchronous electric motor with a squirrel-cage rotor.

Asynchronous motors are the most common and are used in industrial electric drives. This is due to the fact that asynchronous motors are simple in design and operate on a three-phase current network.

Asynchronous motors are built in two versions — with a squirrel-cage rotor and with a phase rotor (with slip rings). Squirrel cage motors are the simplest motors to design and maintain because they have no brushes.

Squirrel cage induction motor

These motors are connected directly to the three-phase current network without additional starting devices. When starting the motor, it draws a current from the network that is 5 to 7 times greater than the operating current of the motor. Therefore, earlier squirrel-cage engines were used only with power up to 100 kW. Currently, in order to reduce the inrush currents of squirrel-cage rotor induction motors, they are used special soft starters and frequency converters.

Asynchronous motors with a wound rotor are used only in cases where it is necessary to regulate the speed of rotation of an induction motor by connecting a rheostat to the rotor circuit, or the power supply of the system does not allow the inclusion of a squirrel cage electric motor with high power due to excessive voltage drop during on startup.

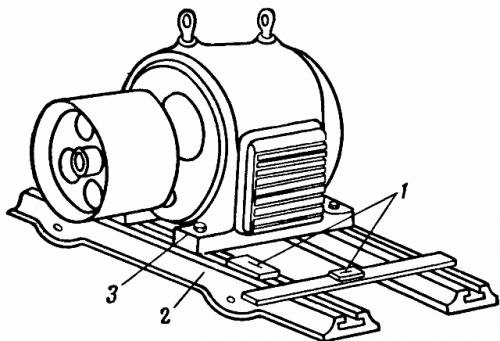

Leveling of the foundation horizontally by levels: 1 — hydrostatic levels

Electric motors are mounted either on a foundation or on frames assembled from steel structures. Belt drive machines are usually mounted on sliders 2 that allow belt tension to be adjusted. The sliders are cast or welded beams in the form of troughs, inside which special sliders move. Bolts 3 passing through the legs of the bed are screwed into them. The sliders are installed by engaging the slider teeth.

By tightening the adjusting bolts placed on the legs of the bed, you can move the machine parallel to its axis and tighten or loosen the belt. If the machine is driven by a clutch, then the machine is mounted on a frame or foundation. The methods of installing low-power machines are very different. They can be installed normally (legs down), on a wall or on a ceiling.

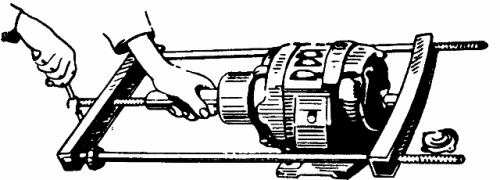

Before starting the assembly, the pulley, gear or half-coupling is placed on the end of the shaft. Under no circumstances should these parts be hammered onto the shaft as this may damage the bearings. Sometimes there is even displacement of the rotor along the shaft.

The figure below shows a screw device for attaching a roller to a shaft.

Shikva shaft attachment

When using this device, the force of the nozzle is perceived by the shaft, at the end of which the hinge of the device rests. To do this, the bearing cover must be removed from the side opposite the drive. To mount the pulley on the shaft of a larger machine, you can use a screw jack, using building walls or columns as support. The horizontal position of the mounting plane is checked using levels, which must be placed in two perpendicular positions.

One of the main installation operations of electrical machines is alignment, which is designed to achieve the correct relative position of the connected shafts, ensuring trouble-free operation of the machines. For this it is necessary that the axes of the shafts lie on the same line and the centers of the shafts coincide. The most common is centering using two clamps fixed on the half-couplers of the connected machines.

Read more about installing electrical machines here:

Installation of pre-assembled eclectic motors

Installation of electric motors with a phase rotor

Installation of electrical equipment on overhead cranes

Safety when installing electric motors

Installation of electrical equipment

Various types of electrical devices are used to control the operation of electric motors, generators and electrical networks. They serve to turn on and off electrical equipment and individual sections of the network, to regulate the current in the windings during the start and operation of electric motors and generators, to protect against overload and short circuit, to change the speed and direction of rotation.

Electrical devices are also used for the automation of technological processes, for various special purposes, such as electric contact welding, clamping of parts during processing, signaling and production control, etc.

Control mechanisms and protective devices are a very important part of electrical equipment, therefore their installation must be of high quality and ensure the reliability of the operation of electric drives.

Before installation, all devices undergo a thorough inspection to verify their functionality. Each device is placed in a special housing, in the legs of which there are holes for fastening. Through these holes, markings are made in the panels and frames on which the devices are mounted. Many modern electrical devices are designed to be mounted on a DIN rail, which greatly facilitates their installation.

The metal covers of the apparatus must be connected to the ground network. Multi-core and single-core wires connected to devices with a cross-section of more than 10 mm2 must have mechanical handles or lugs.

More information on the installation of various electrical devices is described here:

Installation of magnetic starters