What are cable joints for, types of joints

Any insulated cable that carries the function of a conductor of electrical energy, especially at the scale of the electrical network, must necessarily be dense and sealed to protect its conductors from unauthorized short circuits and from any external influences, such as grounding moisture, as well as from excessive mechanical overloads characteristic of communications laid underground.

The length of such cable communication can be tens of kilometers, while the installation length of a piece of cable is usually limited by the size of the transported coil. For this reason, often extended cable communication must be composed of fragments of the maximum length available, connected in series, and the already obtained structure must be connected when necessary.

To solve the described problem, connecting transition and end connectors are used. Connectors allow you to connect cables of different types and are used to combine pieces of cables into a single unit. To put the resulting cable in a trench and bury it.Terminals are needed to connect the ends of cables to panels or other equipment.

The requirements for all characteristics and parameters of the power cable connector are quite strict. The coupling must ensure minimal losses of electricity when the current passes through the junction. Therefore, it is extremely important that the contact area at the wire-bond and wire-bond transition is slightly larger than the cross-section of the wire.

The pressing force of the bushing should ensure a very tight contact and maximum conductivity of the finished joint. That is why special bushings with fasteners and crimping are used to fasten any connectors (connecting and end).

The insulation of the connector and the connection as a whole must withstand the phase-to-phase voltage with a margin, be mechanically strong and moisture-resistant, taking into account the permanent presence of the cable in the ground.

When choosing a cable connector, it is necessary to be guided by the following parameters: the number of wires in the cable, the cross-sectional area of the wires, the material of the wires, the maximum voltage, the type of phase-to-phase insulation and the protective sheath of the cable. Depending on the maximum communication voltage, connecting elements are divided into those used for high-voltage networks and for networks with a voltage of less than 1000 volts.

Usually the maximum number of wires connected to one bushing is up to four, but there are also situations, although rare, when there are more than four wires per bushing.

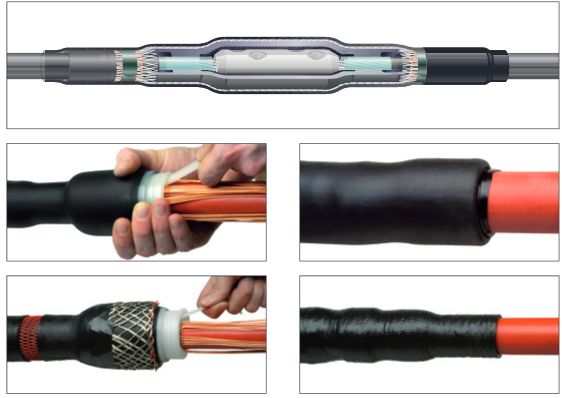

When installing the connector, first cut the ends of the cable and remove the insulation from them, then prepare the surfaces of the wires: the insulation is cut to the length of half of the connector. After that, two ends of the connecting wires are inserted from both sides into the corresponding connecting elements of the connector, and everything is firmly fixed with fasteners. The terminals are fixed in the same way.

Types of connectors

The connector marking contains comprehensive information. For example, the STp-1 4×16-25 cable gland contains the following encrypted information in its name. C — connecting piece. TP — thermoplastic insulation. 1 — maximum network voltage up to 1000 volts (if instead of «1» there was «10» — the maximum voltage would be 10 kV). 4 — the maximum number of connected wires.

16 — minimum wire cross-section — 16 sq. Mm. 25 — maximum wire cross-section — 25 square mm. The letter «C» at the end of the marking, if any, will indicate the presence of additional clamping elements. The letter «P» — the presence of PVC fasteners. If there is a «P» after «Тп» - the clutch is under repair. «B» — sleeve for armored cable. «O» — sleeve for single-core cable.

Another example.

4KVTpN-1-16-25-end sleeve for internal installation without additional fasteners.

If the KVTp cable connection is equipped with universal bolt eyes with shear heads with conductive mastic on the contact surfaces of the NB type, which are used to terminate cables with both aluminum and copper conductors, the letter «N» is added to the designation of the cable connection.

It is also possible to complete the connection with copper or aluminum lugs of the required size for soldering or crimping.The presence of XLPE and PVC insulation is indicated by the addition of the letter «K».

Lead and epoxy connectors are used to connect cables in networks with an operating voltage of 6,000 to 10,000 volts. Epoxy elements are the most resistant to external influences, in addition, they can serve as retaining components of the insulation of the paper cable. Refractory material is placed on the elements. The connector is mounted in a metal housing with a thickness of 5 mm.

Lead pipe connectors are suitable for connecting lead or aluminum braided cables. Such connectors have a length of 45 to 65 cm and a diameter of 6 to 11 cm, they have metal protection on the outside. Also, shut-off connectors are also called connectors that are used to protect the insulation layer from temperature extremes that can lead to unwanted surge.

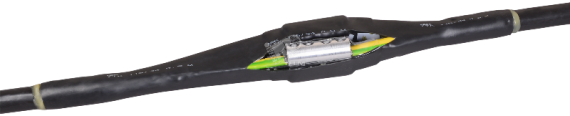

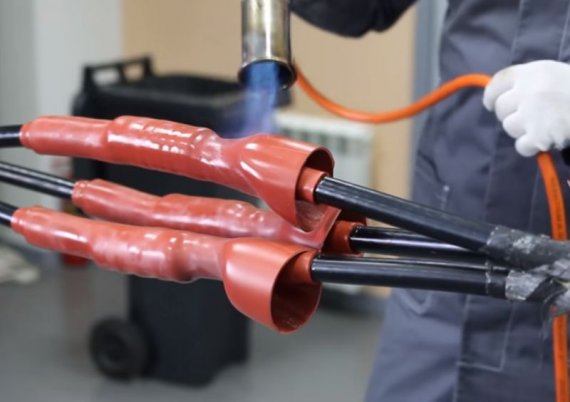

The so-called heat shrinkable plastic sleeves, their installation takes half the time compared to other types of connectors.

The polymer is heated with a gas burner or building hair dryer to a temperature of 150 ° C, while crimping the joint. The insulation is completely sealed and durable because during cooling the material simply sticks to the cable.

The latest elastomers make it possible to realize the so-called Cold shrink. Cold-shrink insulation connectors contain a silicone-based rubber dielectric layer. You don't need to heat anything here, the voltage is enough.

The reinforcement is installed inside a special spiral cord, tension is applied and the element tightly covers the entire insulated area. The cable is then removed and the process of installing the cable, similar to heat shrink, occurs.This method is convenient when there is a risk of fire and therefore a torch or hair dryer cannot be used.