Organization and preparation of electrical works

Currently, electrical work is mainly carried out by industrial methods. The industrial method of conducting electrical work is understood as such a method in which the installation is reduced to the assembly and installation of ready-made factory products delivered to the place of work - full shields, stations, power points, busbar assemblies and blocks, pipe wiring, etc.

When developing projects for electrical equipment, project organizations foresee the possibility of conducting electrical work by industrial methods with maximum use of factory electrical equipment assembled in large blocks and assemblies, standard assembly parts and modern power tools and devices.

Factory products, as well as blocks and assemblies manufactured or assembled in the workshops of assembly and supply sections (MZU), must be fully equipped with the necessary electrical devices and devices connected, have assembly and connection drawings and do not require any additional work at the installation location.

The organization of electrical works by industrial methods provides for preliminary execution outside the installation area, in specially organized installation and installation departments of the installation and supply sections, of all works that are not related to the state of the general construction works of the facility. They include:

-

processing of technical documentation;

-

acceptance and completion of electrical equipment;

-

purchasing products for factory assembly;

-

production and pre-assembly of assemblies, blocks, non-standard electrical structures, etc.

The actual assembly works on the site are organized in such a way that some of them (mostly auxiliary) are carried out simultaneously with the construction works, the other part (main) in the finished premises after the completion of the construction and finishing works. This method of organizing installation work is called two-stage installation.

The industrial method will make it possible to start electrical work without waiting for the end of general construction work, significantly reduce the time for commissioning electrical equipment, reduce costs and improve the quality of installation work.

Sections for assembly and orders (MZU) during assembly departments are organized as part of pre-production groups (GPP), workshop and picking group.

The advance team must:

-

check the work projects of electrical equipment and the organization of work in terms of their compliance with the requirements of the industrialization of electrical works, the presence of errors, the need for revision, etc., as well as solving issues arising from the discrepancy between the electrical part of the project and the actually completed construction-technological part of the facility;

-

prepare technical documentation for the replacement of equipment and materials provided for by the project, but absent at the site;

-

solving the issues of using standard electrical structures and products from factories and developing additional drawings and sketches for advanced assemblies, blocks and products that will be manufactured in the workshop;

-

prepares lists of built-in parts to be installed during the construction works;

-

compile (together with the picking group) selection lists of electrical equipment and materials and specifications for pipes and metal received from the customer;

-

prepares orders for the assembly and supply workshop for the production of assemblies, blocks, non-standard electrical structures and other products that are not supplied by industrial enterprises;

-

develop limit maps for the materials needed to fulfill these orders;

-

to compile a calculation of sales prices for units, blocks and other products not provided for in the current price lists;

-

to develop schemes for carrying out assembly works.

As part of the production preparation group, there are special fitters-measurers who perform sketches of details from measurements from nature.

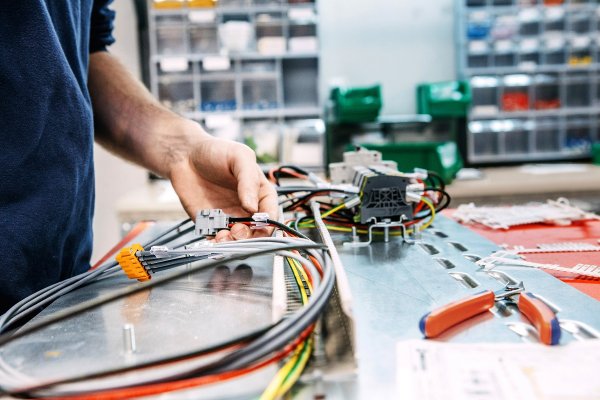

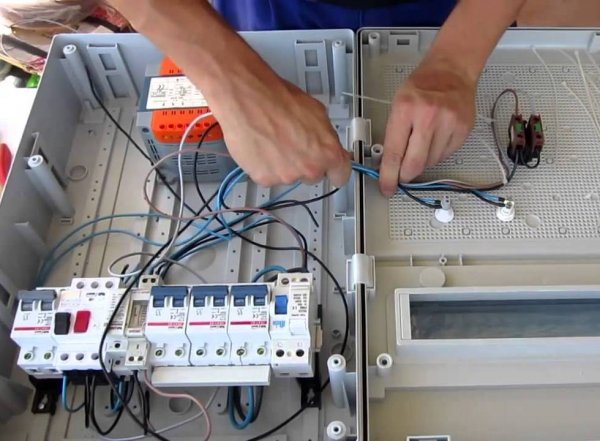

The shop completes, assembles and manufactures extended shield blocks, power points, magnetic starters, buttons, cable structures, workshop trolleys, heavy busbars, steel pipes, etc., as well as pipe wiring assembly units with expansion and junction boxes, grounding devices with fasteners, lighting fixtures with clamps or hangers with tightened wires, etc. Workshops also produce non-standard electrical structures, fasteners, installation and other products and parts that are not supplied by industrial enterprises.

For the production of units and blocks, electrical structures and other products, special technological lines are created in the workshops for processing sections of steel and sheet metal, blanks for pipes and busbars, blanks for electric wires, etc. Such technological lines are equipped with special devices for performing all assembly operations in the line.

The assembly group assembles the blocks and units produced in the workshops of the assembly and supply sections with equipment, as well as the main and auxiliary materials necessary both for their production and for their installation at the installation site (labels, hardware, tips, etc. n. .), checks the marking and prepares finished products for delivery to assembly sites.

Works on the installation of electrical installations can only be carried out if there is agreed and approved project documentation. The range of project materials handed over to installation organizations includes an explanatory note, specification of electrical equipment and materials, cost estimates and working drawings.

The explanatory note provides a brief justification and explanation of the main decisions made in the project regarding the choice of electrical equipment, power circuits, the type of wiring, the way of laying wires and cables and the necessary installation instructions related to the characteristics of this production.

The specification for electrical equipment, electrical structures and materials contains all the necessary data for their order (technical characteristics, quantity, weight).

A list of industrial blanks is attached to the specification, which indicates which electrical structures and products are supplied by electrical plants or specialized organizations for electrical installations and which must be made in the workshops of the assembly and supply sections of the assembly departments.

The bill serves as the main document that determines the volume and price of installation work; on its basis, mutual calculations are made between the installation organizations and the general contractor (client).

Working drawings include plans and sections of the site (workshop) to be installed, on which all installed electrical receivers, distribution points, starting devices, power and distribution network, grounding network, as well as circuits of the power and distribution network, protection are installed and automation, etc.

With a large number of cable and pipe lines, a cable or pipe shop is attached, which lists individual sections of cable or pipe wiring, indicating the number and length of the section, where it comes from and where it goes, the brand and cross-section of the cable or wire, and the diameter of the pipes.

The working drawings of projects for electrical installations must provide for the execution of electrical works by industrial methods in two stages and the use of modern installation mechanisms, tools and devices.

The drawings must indicate all assemblies and blocks assembled and completed in the workshop of the assembly section. In turn, workshops, when pre-assembling these units and blocks, must use standard prefabricated assembly products (racks, brackets, boxes, cable structures, perforated strips, mounting profiles, etc.).

As already mentioned, electrical work in the facility itself is carried out in two stages:

-

at the first stage, they perform all the preparatory work — install built-in parts in building structures for fastening electrical equipment, install cable structures, install cranes and crane trolleys, prepare routes for laying electrical wires and grounding wires, lay pipes for electrical wiring, etc. . The work of the first stage is carried out simultaneously with the production of main construction works;

-

at the second (main) stage, electrical equipment and electrical structures are assembled, assembled into blocks and units, cables are laid along the installed structures, and wires of the power and lighting networks are laid on ready-made blanks and connected to the installed electrical equipment — electrical machines, starting devices , lamps, power points, lighting shields, etc. The works of the second stage, as a rule, are carried out after the completion of construction and finishing works.

Built-in parts and details are installed by the builders according to the drawings made in accordance with the tasks available in the electrical part of the project. In precast concrete building structures, the embedded parts are installed during the production of a block in a factory or depot.

Embedded parts can also be installed in openings in precast concrete products or embedded in the joint seams of reinforced concrete slabs. In some cases, different designs such as laps or checkers may be used on trusses and columns.

The joint implementation of construction and preparatory electrical works is carried out in the following order:

-

steel pipes of electrical wiring are laid in the finished formwork of the foundations of the equipment after the installation of the formwork and foundation bolts;

-

laid on ceilings for pouring with concrete after the end of concreting the floors, removing openings and installing the formwork of pits and channels;

-

laying for hidden wiring after the end of the masonry of the walls and the arrangement of ceilings and floors (with prepared channels and niches);

-

built-in parts are installed for fastening assemblies, blocks and electrical structures after the end of the masonry of the walls and the device of ceilings and floors;

-

for fixing open wiring on reinforced concrete structures after the end of pouring and monolith (with stripping) of building structures;

-

open pipe wiring and grounding networks are installed after the completion of the plastering of walls and ceilings and the installation of flooring;

-

structures for fixing open wiring are installed after the end of the plastering of walls and ceilings, and on steel and reinforced concrete structures after the end of pouring and for monolithic building structures, workshop trolleys after the completion of laying and alignment of rail cranes, lighting networks and supply lines laid along trusses in cranes, after the crane has been started;

-

cable structures and built-in parts in tunnels, wells from block channels and channels are installed after completion of masonry or concreting of walls and ceilings, plastering, installation of frames and overlapping plates and hatches, removal of construction waste and water pumping;

-

wires and cables are pulled into the pipes after finishing the room, and the installation of open wiring - after the final completion of walls, ceilings and open structures of floors, trusses, etc.