Installation of electrical wires on cable ducts

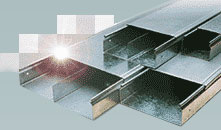

Cable trays

The open laying of wires and cables, using trays, greatly reduces the time-consuming operations of fixing wiring and without scarce pipes. This type of laying provides good conditions for cooling wires and cables, free access to them, as well as the possibility of changing them during work.

Trays for electrical wiring are produced in sections 2 m long, welded with a width of 200 and 400 mm, perforated 50 and 100 mm.

Requirements for mounting cable trays

The trays are installed at a height of at least 2 m from the floor or service platform. In the serviced premises specially trained personnel, the height of trays and boxes is not standardized.

The trays are installed at a height of at least 2 m from the floor or service platform. In the serviced premises specially trained personnel, the height of trays and boxes is not standardized.

Metal trays are installed on prefabricated cable structures, building elements, brackets and hangers. Cable fixing step 250 mm.

All connections during installation are made with threaded fasteners. The electrical contact between the sections of the trays is ensured by fastening the elements.

Technology for installation of electrical wires in cable trays

The operations of installing electrical wiring in trays are carried out in a certain sequence.

First, they mark the route with a marking cord and outline the places for mounting supporting structures to the construction elements of the building.

After that, the supporting structures are installed, which are fixed with a spacer or dowels for guidance. In addition, blocks of 6 — 12 m are assembled from separate sections of the blocks, connecting them with bolt strips.

They then prepare the measured lengths of wires and insulation at their connection points. They call and twist the wires, control the correctness of the connections, install boxes in the necessary places. The wires are bundled, tied and labeled.

The number of wires in the bundle should be no more than 12, the outer diameter of the bundle should be 0.1 m. The distance between the strips in the horizontal sections of the bundle should be 4.5 m and no more than 1 m in the vertical ones.

When laying wires and cables in trays in rows, bundles and bundles, the following gap is maintained: with a single-layer laying of 5 mm in light; when laying in bundles of 20 mm between the bundles; with multi-layer sealing without gaps.

Methods of laying cables in trays

Marking labels are installed at the edges of the trays. Check the continuity of the "phase-zero" circuit, the contact connections and measure the insulation resistance with a megohmmeter.