Installation of grounding and neutral protective wires

Grounding and neutral protective conductors of indoor and outdoor installations must be accessible for inspection. This requirement does not apply to neutral conductors and metal sheaths of cables, pipes with hidden electrical conductors, metal structures and pipes located in the ground and foundations, as well as grounding and neutral protective conductors laid in pipes and ducts and in hidden irreplaceable electrical wiring .

The earthing conductors are laid horizontally and vertically or parallel to inclined building structures.

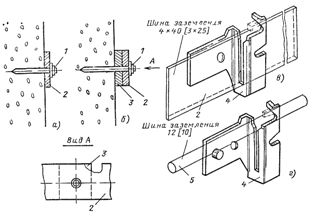

In dry rooms grounding conductors on concrete and brick foundations, they can be laid directly on the foundations by fastening the strips with dowels-nails, and in damp, especially damp rooms and in rooms with corrosive vapors, the wires are laid on pads or supports ( holders) at a distance of at least 10 mm from the base.

Rice. 1.Fixing of grounding conductors of steel strip: a — directly to the wall, b — on pads, c — on a strip steel holder, d — same for round steel 1 — dowel, 2 — strip (earthing bus) 3 — strip steel lining , 4 — holder for flat and round wires 5 — round steel (earthing bus).

Ground wires are fixed at distances of 600 — 1000 mm between fasteners on straight sections, 100 mm at bends from the tops of corners, 100 mm from branching points, 400 — 600 mm from the floor level of the room and at least 50 mm from the lower surface of the movable ceilings of the channels. Through walls, partitions and ceilings, the grounding wires are laid in open holes or in sleeves, and compensators are installed at the intersection of expansion joints.

Ground wires are fixed at distances of 600 — 1000 mm between fasteners on straight sections, 100 mm at bends from the tops of corners, 100 mm from branching points, 400 — 600 mm from the floor level of the room and at least 50 mm from the lower surface of the movable ceilings of the channels. Through walls, partitions and ceilings, the grounding wires are laid in open holes or in sleeves, and compensators are installed at the intersection of expansion joints.

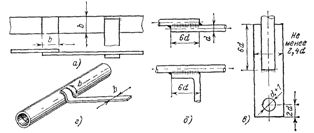

Connection of grounding wires and their connection to the metal structures of buildings is carried out by welding, with the exception of separate places intended for measurements. The length of the overlap for welding wires during the connection is taken to be equal to the width of the strip with a rectangular cross-section and six diameters with a circular cross-section.

Grounding conductors are usually connected to the housings of electric motors and electrical appliances under the grounding bolt of their housings. Motors mounted on skids are grounded by connecting a ground wire to the latter.

The method of connecting the ground wires and connecting them to the ground bolts is shown in Fig. 2. If valves, water meters or flange connections are installed on pipelines used as grounding conductors, then bypass jumpers with a cross section of at least 100 mm are welded or mounted on brackets in these places.2.

Rice. 2. Connection and connection of grounding conductors: a — connection by welding of strip steel, b — connection by welding of round steel, c — connection to earthing bolt of round steel, d — connection to pipeline of steel strip by welding.

Open earth and neutral protective conductors have a distinctive color — a yellow stripe along the conductor on a green background. Places intended for connection of portable grounding wires shall not be painted.