Installation of electrical cables in plastic cable boxes

Currently, plastic cable ducts (cable ducts) are most often used for laying cables in office and administrative premises.

Currently, plastic cable ducts (cable ducts) are most often used for laying cables in office and administrative premises.

Cable trays are varied in shape and materials from which they are made. Cable trays are available in plastic, metal and wood. The most popular are plastic cable ducts made of self-extinguishing, impact-resistant and heat-resistant PVC. These cable ducts are resistant to fire, chemicals and acids.

They perform the function of additional insulation and protection against mechanical damage, allow easy access to the electrical wires placed in a plastic box. Sockets installed in the box can be easily moved to any convenient place and, if necessary, new ones can be added, which is most important for office premises.

They perform the function of additional insulation and protection against mechanical damage, allow easy access to the electrical wires placed in a plastic box. Sockets installed in the box can be easily moved to any convenient place and, if necessary, new ones can be added, which is most important for office premises.

Plastic cable channels are convenient in design, economical, have an aesthetic appearance and are easy to install and operate.

Plastic boxes are available in different thicknesses and widths.According to the produced dimensions, cable channels can be divided into micro channels (sizes from 12×7 mm to 16×12 mm), mini channels (from 22×10 mm to 40×16 mm), cable channels with standard (100×40 — 100× 50 mm) and large sizes (100×60 — 200×80 mm).

Plastic boxes are available in different thicknesses and widths.According to the produced dimensions, cable channels can be divided into micro channels (sizes from 12×7 mm to 16×12 mm), mini channels (from 22×10 mm to 40×16 mm), cable channels with standard (100×40 — 100× 50 mm) and large sizes (100×60 — 200×80 mm).

Many types of plastic boxes are manufactured and sold with additional accessories. In addition, they can have compartments (sections) along the entire length inside, which makes it possible to separate the wiring into separate groups.

Selection of cable trays

The pipe size can be determined by the formula:

C (n NS d2) / k,

where S is the cross-sectional area of the cable channel, mm2, n is the number of wires laid in it, pcs, d is the diameter of the wire, mm2, k is the filling factor (0.45) — due to the need to ensure effective dissipation of the heat.

In accordance with this formula, plastic trunks are selected for laying network cables in buildings.

So for example, to put 10 cables, you need a box with area S> (10 x 62 ) / 0.45 = 800 mm2

Based on the obtained value, the closest in size box size is selected from the standard denominations.

Installation of plastic cable ducts (cable ducts)

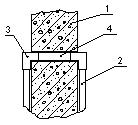

Depending on the category of the adjacent rooms, the passages through the walls are made open or sealed. For indoor heated rooms, the aisles are open. For this, holes are drilled in the walls of the working rooms, in which the built-in pipes are installed (Figure 1).

Rice. 1 Cable passage through the wall 1 — wall; 2 — plastic box; 3 — branch; 4 — built-in pipe

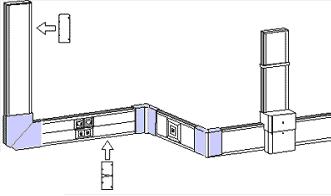

Horizontal cable channels are equipped with sockets for each workplace. Most manufacturers' sockets install with a simple click.

Rice. 2.Installation diagram of Legrand cable channels

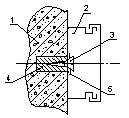

Depending on the type of supporting structure, different types of box fastening (screws, nails, silicone) can be used. An example of fixing the box with screws is shown in figure 3.

Rice. 3. Fastening boxes to the supporting structure 1 — supporting structure; 2 — box; 3 — screw; 4 — cork; 5 — washer