Electric welding of aluminum wires by contact heating

Electric contact welding is the most common type of welding used to terminate and join aluminum conductors of wires and cables.

Electric contact welding is the most common type of welding used to terminate and join aluminum conductors of wires and cables.

Welding of aluminum single-core wires with a total cross-section when twisted up to 12.5 mm2. Electric welding of joints and branches is carried out using a VKZ apparatus without flux. The insulation is removed from the ends of the wire with pliers 35 — 40 mm long), cleaned with a brush for cardo tape or sandpaper to a metallic shine and twisted together.

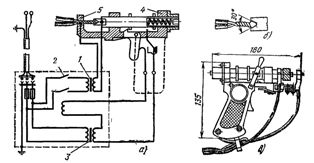

After that, the welding device of the VKZ apparatus (Fig. 1) is prepared for welding: its carbon electrode is returned and the twisted veins are gripped with the jaws of the holder so that the ends of the twisted veins rest in the opening of the carbon electrode.

By pressing the trigger, the device is turned on, then the carbon electrode under the action of a spring and as the ends of the veins melt, move forward and weld them, welding automatically stops at the moment when the connected veins melt to a predetermined length. The joint is insulated with a polyethylene cap or insulating tape.

Rice. 1. Automatic electric welding by contact heating of single-wire aluminum wires with a total cross-section of up to 12.5 mm2 with a VKZ apparatus: a — diagram of the apparatus, b — position of the welded wires in the carbon electrode during welding, c — general view of the apparatus , 1 — welding transformer 220/10 V, 2 — switching relay, 3 — control transformer 220/36 V, 4 — welding device (gun), 5 — wire holder sponge until welded

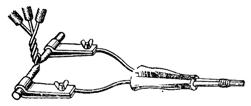

Welding of the specified single-wire cores by contact heating in the assembly area is carried out using pliers with two carbon electrodes (Fig. 2) connected to the poles of the secondary winding of the transformer 9-12 V, 0.5 kV-A.

Rice. 2. Electric welding by contact heating of single-wire aluminum wires with a total cross-section of up to 12.5 mm2 in pliers with two carbon electrodes

The preparation of the wire for welding is carried out in the same way as when welding with the VKZ apparatus, only the insulation is removed from the wire at a length of 25-30 mm (instead of 35-40 mm) and a thin layer of flux is applied to the wire before welding in length 5-6 mm.

When welding in tongs with two carbon electrodes, the twisted veins are placed vertically with their ends down, then the ends of the carbon electrodes are brought together until they touch while the electrodes are heated.The hot electrodes are pressed against the ends of the wires until the aluminum melts and a weld ball is formed.

After cooling, the welded joints are cleaned of slag and flux residues with a steel brush or sandpaper and insulated with a polyethylene cap or insulating tape.

Stranded wires with a total cross-section from 32 to 240 mm2. The connection and branching of the cores is carried out by merging into a common monolithic rod.

For welding, a welding transformer with a secondary voltage of 8-9 V with a power of 1-2 kV-A is used, an electrode holder with a carbon electrode and a cooler are connected to the transformer, suitable shapes are selected according to the section, filler rods are prepared from aluminum wire with cross section 2.5 — 4 mm2, and their surface is thoroughly cleaned with a cardo tape brush or sandpaper and degreased with a cloth soaked in gasoline.

Before starting welding, the filler rods are coated with a thin layer of flux. The insulation is removed from the ends of the core along the length: with a total cross section up to 50 mm2 — 60 mm, 75 mm2 — 65 mm, 105 mm2 — 70 mm, 150 mm2 — 72 mm, 240 mm2 — 75 mm If the cable cores with impregnated paper insulation are prepared for welding, then a threaded bandage is applied to the insulation, after which it is loosened with pliers by twisting the core wires and removing the oil composition from their surface with a cloth soaked in gasoline.

Treated veins are placed vertically with the ends up. A detachable cylindrical form is placed on the veins, which is selected according to the total area of the connected veins, but for the nearest larger area.

On the veins, winding is carried out with an asbestos cord 1-1.5 mm thick, so that the fused end of the veins protrudes from the asbestos bandage, and its end is aligned with the upper edge of the form. Both halves of the form are fastened with a wire strip or a clamp made of thin sheet metal.

A cooler is placed on the core between the mold and the insulating edge. The ends of the veins are covered with a thin layer of flux. Then they begin to weld: they tightly press the end of the carbon electrode to the ends of the veins and hold it like that until the start of melting, then slowly move the end of the electrode along the ends of the veins, melting all the wires one by one.

An additive rod is then dipped into the molten metal, the resulting bath of molten metal is stirred by circular motion of the electrode. After filling to the edges of the mold with molten aluminum, the electrode is withdrawn, the process of melting the end of the core is considered complete.

After the weld has cooled, the coolers and molds are removed and the weld and the adjacent section of the cores are cleaned of slag from the cardo belt with a brush.