Connecting and branching wires by twisting

The method of connecting the wires by twisting is simple to implement, but requires subsequent soldering of the connection. When twisted, the wires have few contact points, and when current passes through the connection, the contact overheats, which can cause a fire. Therefore, connecting wires by twisting without soldering is not allowed. Soldering ensures the reliability of the electrical contact and the required mechanical strength.

The method of connecting the wires by twisting is simple to implement, but requires subsequent soldering of the connection. When twisted, the wires have few contact points, and when current passes through the connection, the contact overheats, which can cause a fire. Therefore, connecting wires by twisting without soldering is not allowed. Soldering ensures the reliability of the electrical contact and the required mechanical strength.

I receive high quality soldering it is necessary to choose the right solder, remove the oxide film on the connected contact surfaces. When connecting copper, the oxide film is removed before soldering, and when connecting aluminum wires - during the soldering process.

The heating temperature of the soldering point should be 30 — 50 ° C higher than the melting temperature of the solder and flux. The low temperature gives the so-called «cold soldering», which has low mechanical strength and creates an unreliable electrical contact.

The soldering iron should not be overheated when soldering.In this case, the rosin starts to burn and instead of cleaning the surface, it contaminates it. To avoid damage to the insulation, a 2-3 mm long section of the core is not tinned before cutting.

A feature of soldering and welding of aluminum wires is that during the soldering process, the oxide film from the surface of the connected wires is removed mechanically under a layer of molten solder or chemically — by using special fluxes that destroy the oxide film at a certain temperature. At the end of soldering, the remnants of the flux are carefully removed, as they can cause the contact to break.

Soldered joints of aluminum wires in humid air are not recommended due to possible corrosion. Soldering points are protected from moisture with protective covers.

Connection and branching of single-core and multi-core copper wires PR, PRVD, PRD are used in open wiring of rolls and insulators. This method is also used in electrical wiring with flat conductors PPV, etc., when the junction boxes do not have an insert with contact clamps.

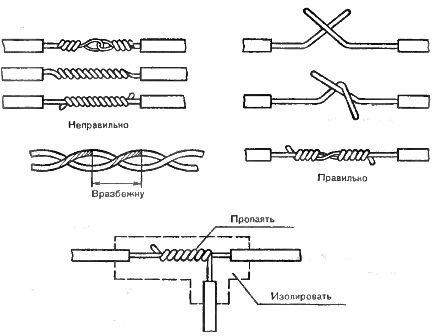

Wire methods are shown in Figure 1.

Rice. 1. Methods of connecting and branching wires by twisting

To connect two pieces of wires, it is necessary to tightly twist the wires of the current-carrying wires and cross the wires. The end of the left wire is made 6 - 8 turns around the right one, and the end of the right wire is also made 6 - 8 turns around the left one, but in the other direction.

Twisted joints should be at least 10-15 diameters of connecting wires. The joints are crimped with pliers soldered with POS-3O or POS-40 solder.The soldered twist is insulated along the entire length of the connection, with the obligatory capture of the uncleaned insulation of the wires. The connection of two twisted wires to each other is done randomly.

Soldering aluminum is done with a soldering iron with solder A. If other solders are used, then a blowtorch is used. Solder A is corrosion resistant, convenient for soldering and tinning. The oxide film of aluminum is mechanically destroyed when a wire is rubbed with solder, so no flux is required when soldering.

When soldering single-wire aluminum conductors with a cross section of 2.5 — 10 mm2, the connection and branching is carried out in the form of a double twist with a groove. The insulation is removed from the cores, sanded to a metallic shine, overlapped with a double twist to form a groove where the cores meet.

The joint is heated with a blowtorch or soldering iron to the point where the shoot begins to melt. With a soldering iron A, strongly rub the groove on one side. As a result of friction, the film peels off and the groove is filled with solder. Similarly, the groove on the other side is filled with solder. After cooling, the twist compound is isolated.