Magnetic starters

Magnetic starters are mainly intended for remote control of three-phase squirrel-cage induction motors, namely:

- for starting by direct connection to the network and stopping (switching off) the electric motor (non-reversible starters),

- for starting, stopping and reversing the electric motor (reversible starters).

In addition, starters in a thermal relay version also protect the controlled electric motors from overloading for an unacceptable duration.

Magnetic starters with an open version are intended for installation on panels, in closed cabinets and in other places protected from dust and foreign objects.

Shielded magnetic starters intended for indoor installation where the environment does not contain significant amounts of dust.

Dustproof magnetic starters designed for both indoor and outdoor installations in locations protected from sunlight and rain (under a canopy).

PML series magnetic starter

Magnetic starter device

Magnetic starters have a magnetic system consisting of armatures and a core and enclosed in a plastic case.Placed on the core of the clamping coil ... Traverse slides on the guides of the upper part of the starter, on which the armature of the magnetic system and bridges of main and blocking contacts with springs are mounted.

The principle of operation of the starter is simple: when voltage is applied to the coil, the armature is attracted to the core, the normally open contacts close, the normally closed contacts open. When the starter is turned off, the opposite occurs: under the action of the return springs, the moving parts return to their original position, while the main contacts and the normally open block contacts open, the normally closed block contacts close.

Reversible magnetic starters are two conventional starters mounted on a common base (panel) and with electrical connections that provide electrical interlock through the normally closed interlocking contacts of the two starters, preventing one magnetic starter from engaging when the other is engaged.

The most common schemes for turning on an irreversible and reversible magnetic starter, see here: Schemes for inclusion of a magnetic starter of an asynchronous electric motor… These circuits provide zero protection by means of a normally open starter contact which prevents the starter from spontaneously turning on when voltage is suddenly present.

Reversing starters may also have a mechanical interlock, which is located under the base (panel) of the starter and also serves to prevent simultaneous activation of two magnetic starters.With electrical interlocking through normally closed contacts of the starter itself (as provided by its internal connections), reversing starters operate reliably even without mechanical interlocking.

Reversible magnetic starter

Reversible motor using a reversing starter, it is carried out by pre-stopping, i.e. according to the scheme: turning off a rotating motor — point — turning on for reverse rotation. In this case, the starter can control an electric motor with the corresponding power.

In case of reversing or stopping the electric motor by counter-switching, its power should be selected 1.5 — 2 times lower than the maximum switching power of the starter, which is determined by the state of the contacts, i.e. their durability when working in an applied mode. In this mode, the starter must work without mechanical blocking. In this case, electrical blocking through the normally closed contacts of the magnetic starter is required.

The magnetic starters of the protected and dustproof versions are closed. Starter housing The splash-proof design has special rubber seals that prevent dust and water splashes from entering the starter. The entrances to the housing are closed with special samples using gaskets.

Thermal relays

A range of magnetic starter thermal relays are supplied which provide thermal protection of the electric motor against overload of unacceptable duration. Current correction for relay setting — smooth and made by the setpoint regulator by turning with a screwdriver. See here for thermal relay device… If it is impossible to carry out thermal protection in repeatedly short-term mode of operation, magnetic starters without a thermal relay should be used. Thermal relays do not protect against short circuits

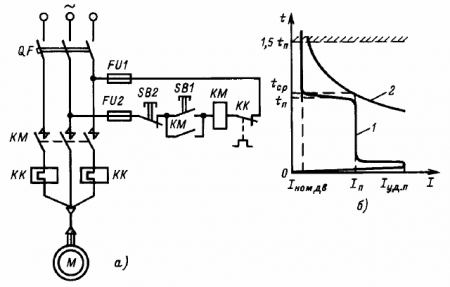

Scheme of direct starting and protection of an induction motor with a squirrel-cage rotor (a), (b) - the starting characteristic of the motor (1) and the protective characteristic of the thermal relay (2)

Installation of magnetic starters

For reliable operation, the installation of magnetic starters must be carried out on a flat, rigidly reinforced vertical surface. It is recommended to install starters with a thermal relay with the smallest temperature difference between the air surrounding the starter and the electric motor.

In order to prevent false alarms, it is not recommended to install starters with a thermal relay in places subject to shocks, sharp shocks and strong shaking (for example, on a common panel with electromagnetic devices for rated currents above 150 A), since when turned on they create great shocks and shocks…

In order to reduce the effect on the operation of the thermal relay of additional heating from external heat sources and to comply with the requirement that the ambient temperature of the air starter is inadmissible above 40 О It is recommended not to place thermal devices (rheostats etc.) and do not install them with a thermal relay in the upper, most heated parts of the cabinets.

When a wire is connected to the terminal of the magnetic starter, its end must be bent into a ring or U-shape (to prevent the spring washers of this terminal from being bent).When connecting two wires of approximately the same cross-section to the terminal, their ends must be straight and located on both sides of the clamping screw.

The connected ends of copper wires must be tinned. The ends of stranded wires must be twisted before tinning. In the case of connecting aluminum wires, their ends must be cleaned with a small file under a layer of CIATIM grease or technical petroleum jelly and additionally covered after removal with quartz-vasileline or zinc-vasileline paste. The contacts and moving parts of the magnetic starter must not be lubricated.

Before starting the magnetic starter, it is necessary to check it from the outside and make sure that all its parts are in good working order, as well as the free movement of all moving parts (by hand), check the rated voltage of the starter coil with the voltage, supplied to the coil, make sure all electrical connections are made according to the diagram.

When using starters in reversible modes, pressing the movable traverse by hand until the main contacts come into contact (beginning of closing), check for the presence of a solution of normally closed contacts, which is necessary for the reliable operation of the electrical interlock.

With the magnetic starter on, a small humming electromagnet typical of laminated magnet systems alternating current.

Maintenance of magnetic starters during operation

Care for beginners should consist, first of all, in protecting the starter and thermal relay from dust, dirt and moisture... Make sure the terminal screws are tight. It is also necessary to check the condition of the contacts.

The contacts of modern magnetic starters do not require special maintenance. The wear period of the contact depends on the conditions and mode of operation of the starter. Cleaning starter contacts is not recommended, as removing contact material during cleaning will reduce contact life. Only in some cases of severe melting of the contacts when the emergency mode of the electric motor is turned off, it is allowed to clean them with a small file.

If, after prolonged operation, the magnetic starter seems to have a rattling character, it is necessary to clean the working surfaces of the electromagnet from contamination with a clean rag, check the presence of an air gap, as well as check the absence of jamming of moving parts and short-circuit cracks the connected turns located on the core.

During disassembly and subsequent assembly of the magnetic starter, the relative position of the armature and core that was before disassembly should be maintained, since their worn surfaces help to eliminate noise. When disassembling magnetic starters, it is necessary to wipe dust from the inner and outer surfaces of the plastic parts of the starter with a clean and dry cloth.