Electric actuator with linear motors

The majority of electric motors are rotary. At the same time, many working bodies of production machines must, according to the technology of their work, perform translational (for example, conveyors, conveyors, etc.) or reciprocating (mechanisms for feeding metal cutting machines, manipulators, pistons and other machines).

The majority of electric motors are rotary. At the same time, many working bodies of production machines must, according to the technology of their work, perform translational (for example, conveyors, conveyors, etc.) or reciprocating (mechanisms for feeding metal cutting machines, manipulators, pistons and other machines).

The transformation of rotary movement into translational movement is carried out by means of special kinematic connections: screw nut, spherical screw gear, gear rack, crank mechanism and others.

It is natural for the constructors of working machines to want to use engines whose rotor moves linearly to drive the working bodies performing forward and reciprocating movement.

Currently, electric drives are developed using linear asynchronous, valve and stepper motors… In principle, any type of linear motor can be formed from a rotary motor by linearly moving the cylindrical stator in a plane.

An idea of the structure of a linear induction motor can be obtained by turning the induction motor stator into a plane. In this case, the vector of magnetizing forces of the stator will move linearly along the span of the stator, i.e. in this case, not a rotating (as in conventional motors), but a traveling electromagnetic field of the stator is formed.

As a secondary element, a ferromagnetic strip located with a small air gap along the stator can be used. This strip acts as a cell rotor. The secondary element is carried by the moving stator field and moves linearly at a speed less than the speed of the stator field by the amount of linear absolute slip.

The linear velocity of the traveling electromagnetic field will be

where τ, m — pole pitch — the distance between adjacent poles of a linear asynchronous motor.

Secondary element speed

where sL — relative linear slip.

When the motor is supplied with standard frequency voltage, the resulting field velocities will be sufficiently high (more than 3 m / s), which makes it difficult to use these motors to drive industrial mechanisms. Such engines are used for high-speed transport mechanisms. In order to obtain lower running speeds and speed control of a linear induction motor, its windings are powered by a frequency converter.

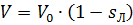

Rice. 1. The design of the linear uniaxial motor.

Several options are used to design a linear induction motor. One of them is shown in fig. 1.Here, the secondary element (2) — a tape connected to the working body, moves along the guides 1 under the action of a traveling electromagnetic field created by the stator 3. However, this design is convenient for assembly with a working machine, it is associated with significant leakage currents of the stator field, as a result of which the cosφ of the motor will be low.

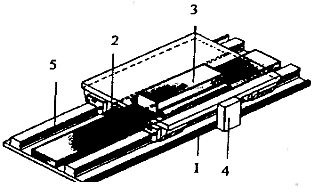

Fig. 2. Cylindrical linear motor

To increase the electromagnetic connection between the stator and the secondary element, the latter is placed in the slot between the two stators, or the motor is designed as a cylinder (see Fig. 2). In this case, the motor stator is a tube (1), inside which there are cylindrical windings (2) which are the stator winding. The ferromagnetic washers 3 are placed between the coils that are part of the magnetic circuit. The secondary element is a tubular rod, which is also made of a ferromagnetic material.

Linear induction motors can also have an inverted design where the secondary is stationary while the stator moves. These engines are generally used in vehicles. In this case, a rail or a special tape is used as a secondary element, and the stator is placed on a movable carriage.

The disadvantage of linear asynchronous motors is the low efficiency and associated energy losses, mainly in the secondary element (slip losses).

Recently, in addition to asynchronous, they began to be used synchronous (valve) engines… The design of a linear motor of this type is similar to that shown in fig. 1. The stator of the motor is turned into a plane, and permanent magnets are placed on the secondary.An inverted design variant is possible where the stator is a movable part and the permanent magnet secondary element is stationary. The stator windings are switched depending on the relative position of the magnets. For this purpose, a position sensor (4 — in Fig. 1) is provided in the design.

Linear stepper motors are also effectively used for positional drives. If the stator of the stepper motor is deployed in the plane, and the secondary element is made in the form of a plate, on which teeth are formed by milling the channels, then with suitable switching of the stator windings, the secondary element will perform a discrete movement, the step of which can be very small — to fractions of a millimeter. An inverted design is often used where the secondary is stationary.

The speed of a linear stepper motor is determined by the value of the tooth separation τ, the number of phases m and the switching frequency

Obtaining high speeds of movement does not create difficulties, since the increase in the division and frequency of gears is not limited by technological factors. Restrictions exist on the minimum value of τ, since the ratio of the pitch to the gap between the stator and the secondary must be at least 10.

The use of a discrete drive allows not only to simplify the design of mechanisms performing linear one-dimensional motion, but also makes it possible to obtain two or multi-axis motions using a single drive.If two winding systems are placed orthogonally on the stator of the movable part, and grooves are made in the secondary element in two perpendicular directions, then the movable element will perform discrete movement in two coordinates, i.e. provide movement in a plane.

In this case, the problem of creating support for the movable element arises. To solve it, an air cushion can be used - the pressure of the air supplied to the space under the moving elements. Linear stepper motors provide relatively low thrust and low efficiency. Their main application areas are light manipulators, light assembly machines, measuring machines, laser cutting machines and other devices.