Calculation of the power of electric motors of mechanisms of metal-cutting machines of a lathe group

When calculating the power of an electric motor with speed control, the mechanical characteristics of the mechanism must be taken into account.

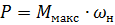

For the basic motion mechanism, in which two-zone speed control is implemented: with constant torque and constant power, the power of the electric motor is calculated by the formula

where: Mmax — maximum resistance under continuous load and maximum equivalent resistance under repeated short-term load; ωn — maximum speed with constant torque adjustment (at nominal flow rate).

For a power drive, the power is determined based on the maximum equivalent torque and the maximum speed. With a large range of speed regulation, it is recommended to use electric motors with independent ventilation or closed type. When using an electric motor with self-ventilation, it is necessary to take into account the deterioration of its cooling at low speeds.

For unregulated engines, as a rule, operating in S6 mode (if the cycle does not exceed 10 minutes), the power calculation is carried out as follows.

The power of the electric motor for each operation is determined by the formula:

where: Pzi, η — cutting power and efficiency of the machine, respectively.

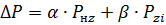

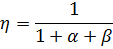

The load-dependent efficiency is determined based on the power losses, based on the expression:

where: Pnz — nominal cutting power; α and β — constant and variable loss coefficients.

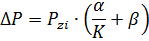

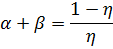

Taking into account the load factor

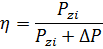

Machine efficiency

For the K = 1 case

Dividing the losses to determine the efficiency at each load gives

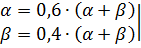

Preliminary for practical calculations is accepted

For drives of the main movement of turning, milling, drilling machines, the efficiency under constant load is 0.7 ... 0.8, for grinding machines 0.8 ... 0.9. The power of the electric motor at idle revolutions of the machine is determined by the formula:

The duration of the operation for each transition is determined by the formula:

where: l — transition length, mm; S — feed, mm / rev; n — speed of rotation of the spindle, rev / min.

The time to install and remove the part is equal to 1-3 minutes. Based on the calculated power and time for each operation, a load diagram is constructed and the equivalent power is determined.

When using an electric drive with speed control, the most severe operating mode is assumed when selecting a motor in terms of power, both in terms of load and starting frequency per hour.

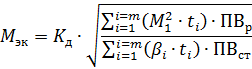

In this case, the preliminary selection of the electric motor is carried out according to the equivalent torque, taking into account the safety factor for dynamics within the limits of Kd = 1.1-1.5 and the most likely duration of inclusion.

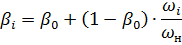

where: βi — coefficient that takes into account the deterioration of the cooling of the electric motor in the i -th interval, when the speed drops below the nominal;

β- coefficient of deterioration of heat transfer in case of stationary armature; PVR, PVst — calculated and standard value of the duration of inclusion.

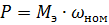

Engine power is determined by the formula

An overload and heating capacity check is then carried out, taking into account the actual moment of inertia of the motor, the workpiece and the mechanical parts of the machine.