Requirements for the mechanical characteristics of electric drives of crane mechanisms

The choice of the electric drive system of the crane mechanism is largely determined by the requirements for its mechanical characteristics, which vary depending on the type of technological operations performed by the crane. For example, the high accuracy of assembly operations performed with a crane requires high rigidity from the characteristics of electric drives with a significant control range, while for magnetic cranes transporting scrap, shavings, etc., these requirements do not play such an important role.

The choice of the electric drive system of the crane mechanism is largely determined by the requirements for its mechanical characteristics, which vary depending on the type of technological operations performed by the crane. For example, the high accuracy of assembly operations performed with a crane requires high rigidity from the characteristics of electric drives with a significant control range, while for magnetic cranes transporting scrap, shavings, etc., these requirements do not play such an important role.

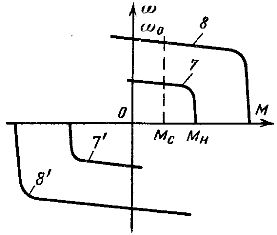

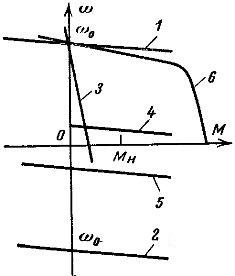

In most cases, for cranes, generalized characteristics of the electric drive can be reduced to those shown in fig. 1 and 2.

Each of them has a specific purpose:

-

Functions 1 and 2 are used to raise and lower loads at high speed;

-

characteristic 3 and similar are necessary for smooth starting of the motor with rheostat regulation and sometimes serve to obtain intermediate speeds of movement of loads;

-

hard characteristic 4 in some cases is necessary to fine-tune the load to a certain level when lifting it;

-

characteristic 5 allows the lowering of light and heavy loads at low speed in the braking mode (quadrant IV), as well as the lowering of light loads and an empty hook when it is necessary to use the power mode (quadrant III);

-

characteristic 6 is necessary for mechanisms operating with a possible sudden overload, for example, for grabs.

Rice. 1. Mechanical characteristics of electric drives of crane mechanisms.

Rice. 2. Mechanical characteristics of electric drives of crane mechanisms with torque limitation.

It should be noted that in some cases, especially for motion mechanisms, the main requirement for the mechanical performance of an electric drive is to maintain a constant acceleration when the motor is started. Such a mode of operation can be obtained, for example, in the presence of the characteristics shown in fig. 2. Low speeds of movement with a shaft moment equal to Ms and low acceleration are provided by characteristics 7 and 7', and increased speeds and accelerations — by characteristics 8 and 8'.

The given graphs (Fig. 1) make it possible to judge which propulsion system should be selected if a certain set of characteristics is required. It is obvious, for example, that characteristics 1, 2, 3 can be obtained from a conventional wound-rotor induction motor with rheostat regulation in the rotor circuit.

The electric drive will be more complex if it needs to have characteristics 1, 2, 3, 5.In this case, you can use an asynchronous motor with a phase rotor and chokes, a saturation voltage regulator or a thyristor in the stator circuit, an asynchronous motor with a phase rotor and a shaft vortex generator. The given characteristics can be obtained from electric drives with DC motors.

The choice of an electric drive system cannot be completed by considering only the possibility of obtaining certain mechanical characteristics from it. It is also necessary to evaluate its dynamic qualities, economic indicators, reliability and ease of maintenance.

At the same time, it should be noted that the general image of the characteristics required for crane mechanisms (Fig. 1) does not give a complete idea of the requirements for the electric drive of cranes. In order to fully understand what the requirements are for an electric drive with characteristics 4 and 5, it is necessary to know the minimum speed at the rated load and the stiffness of the characteristics, or the control range and the required overload torque at the minimum travel speed.

When specifying the above indicators, attention should again be paid to the technological requirements. Taking into account the rigidity of the characteristics required for example for the mechanisms of assembly cranes, the accuracy of stopping when carrying out the operations of lowering and lifting loads must first be considered.

If this accuracy is a few millimeters during lifting operations, then the minimum speed of lifting the load will be 0.005-0.02 m / s at a nominal speed of about 0.1-0.5 m / s.Note that the figures given can be used to directly determine the required steering range. Therefore, it is very important to correctly establish the requirements for the braking accuracy of the electric drive.

In some cases, obtaining a certain type of mechanical performance essentially dictates the choice of an electric drive system. So characteristics 6, 7, 8 (Fig. 1 and 2) required for grippers can be provided with the best performance by the system controlled converter - DC motor. This decision is also due to the fact that electric drives of shaking mechanisms usually require two or three more intermediate reduced speeds and this determines the need for additional regulating characteristics.

When creating an electric drive system for crane mechanisms, it is essential to obtain characteristics similar in appearance to characteristics 3 and 7 (Figs. 1 and 2), which provide a reduction in shock loads on the mechanism when sampling loose rope and backlash in gears.

To clarify this position, it should be noted that during the operation of the electric drive of the lifting crane mechanism, such a mode often occurs when the engine starts to rotate, and the load is at rest. After removing the slack in the rope and clearances, the load starts moving with a bang, as the engine may have reached considerable speed by this time. In this case, the so-called pickup mode takes place.

If at the same time the characteristic of the engine is rigid, then the rope and the mechanism experience shock loads, which lead to their increased wear.In addition, the risk of shaking the load increases.

With soft characteristics, when the ropes are pulled and clearances are removed, the torque developed by the motor increases and its speed decreases. Therefore, when the load starts to move, the impact on the mechanical equipment is greatly reduced. To a lesser extent, due to the manifestation of only the presence of backlash, a reduction of shocks with a soft starting characteristic is also observed in the movement mechanisms.