VLT AQUA Drive frequency converters for pump units

In modern pumping installations, the most widespread is an electric drive with frequency control. The basis of this type of drive is a semiconductor frequency converter. First semiconductor frequency converters began to be used in pumping units in the late 1960s.

In modern pumping installations, the most widespread is an electric drive with frequency control. The basis of this type of drive is a semiconductor frequency converter. First semiconductor frequency converters began to be used in pumping units in the late 1960s.

Danfoss was one of the first to use semiconductor frequency converters in the drive of centrifugal installations. It was the first in the world (since 1968) to produce a series of frequency converters used in pumping installations.

Using its many years of experience in the use of frequency converters in this branch of technology, the company has created a series of frequency converters VLT AQUA Drive intended for use in pumping installations of water supply and sewage systems. VLT AQUA drive converters are manufactured for drives from 0.37 kW to 1400 kW.

The power factor of the converter is also quite high (cosphi ≥ 0.9), so using a variable drive based on the VLT AQUA Drive converter does not require additional devices that increase cosphi (static compensating batteries, etc.).

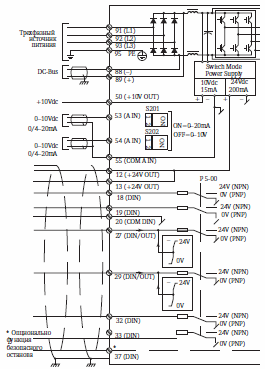

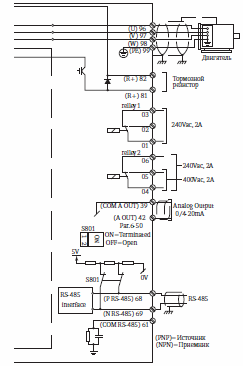

In fig. 1 shows a schematic diagram of the VLT AQUA Drive transducer and a typical external connection diagram (power supply, pump motor, sensors, etc.). The external view of the VLT AQUA Drive converters is shown in fig. 2.

Rice. 1. Connection diagram of the VLT AQUA Drive converter

Rice. 2. Frequency converters «Danfoss» VLT AQUA Drive series

The VLT AQUA Drive is intended for use in pumping installations for water supply, waste water disposal and irrigation systems. In this regard, it has a number of special features that provide the properties required to operate in these conditions, which are listed below.

1. The converter control system provides automatic regulation of proportional-integral controllers, due to which the gains of the PI regulators are adjusted depending on the response of the control object (reservoir-pump-water line) to changes in the entered operating mode of the system variable drive.

Thanks to this property, the PI controller is individually adjusted for each specific object and does not require precise adjustment of the proportional (P) and integral components of the controller when commissioning the converter.

2. The VLT AQUA Drive converter control system ensures gradual filling of the empty pipeline, preventing the risk of hydraulic shock and consequent damage to pipes and hydromechanical equipment.This property is especially valuable for irrigation pumping units, which are often included in the operation of empty water pipes. The filling of the water supply is carried out by a signal pressure sensor in a few steps.

3. The control system of the VLT AQUA Drive converter has the ability to signal the drop of pressure in the pipeline below the set value when the pump reaches the rated speed (point A). This signal indicates the need to turn on an additional pump if a group of pumps is running on the water line.

If a single pump is intended to operate on isolated water mains, the signal indicates a water break or a large water leak from the system. In this case, the pump unit is turned off and measures are taken to eliminate the malfunction of the water supply.

4. The converter control system has the ability to regulate the speed of the pump when it is stopped. Thanks to this property, the rotation speed is gradually reduced to the rotation speed corresponding to the moment of closing the valve, which prevents the occurrence of water hammer in the system and mechanical influences on the valve itself.

5. The VLT AQUA Drive inverter control system has the ability to detect dry running. The system continuously evaluates the pump's operating conditions based on the measurement results of the drive parameters (drive speed and power). At low energy consumption, which occurs with too little or no flow, the pump unit stops.

6. The VLT AQUA Drive frequency controller can operate in sleep mode.This mode is understood as the operation of the pump with a very low flow rate, which corresponds to low energy consumption. This usually happens when the pump is running at low speed.

The control system, comparing the speed of the pump and the power consumed by it, puts the system into «sleep mode». At low flow, the pump increases the pressure to the required value and stops. In addition, the control system monitors the pressure in the water supply system or the level of wastewater in the receiving tank of the sewage plant.

When the pressure in the water supply system drops or the level of wastewater in the receiving tank of the pumping station rises, the pump is put into operation. Due to the property of the control system to provide a «sleeping mode», the wear of the pumping unit is reduced, preventing its operation with a small water intake or a small flow of waste water in the receiving tank of the pumping station. The presence of this function of the converter allows to save an average of 5% of the energy consumed for the water supply.

7. The control system of the VLT AQUA Drive converter has a function due to which the pressure loss in the water line from the pumping station to the dictating point of the water network is taken into account. Thanks to this function, the required pressure is adjusted at the outlet of the pumping station in accordance with the changing water supply. This takes into account that the pressure loss in the pipes is proportional to the square of the flow rate.

This property makes it possible to provide the necessary head at the end of the water line without a pressure sensor.However, it can be effectively used only in the absence of intermediate water drainage along the pipeline.

8. Along with the mentioned properties of the VLT AQUA Drive converter of the control system, the following should be noted:

-

ensuring a smooth start with a given intensity of starting and stopping the pump, which prevents damage to the pump bearings, reduces the likelihood of hydraulic shock in the pipelines, reduces starting currents in the power supply network;

-

ensuring the alternation of pumping units as working and in standby mode. This ensures uniform wear of the motor resource of the pumping units;

-

Converter payout indication showing how much time is left until the VLT AQUA Drive is fully restored.

In addition, we separately note special energy-saving features of variable frequency drives based on Danfoss converters.

1. AEO function (automatic energy optimization function). Thanks to this function, the drive consumes as much energy as is necessary to supply liquid at a given time.

Using this feature saves an additional 5-10% energy. In addition, this feature reduces drive consumption reactive power and, accordingly, the load current of the electric motor. This function is particularly effective for mechanisms with fan drag moment (the drag moment is proportional to the square of the speed), including centrifugal pumps. This feature also reduces the acoustic noise of the device.

2.Automatic motor adaptation function built into the inverter.The regulation of the frequency converter depends significantly on the internal parameters of the electric motor (resistance, inductance, etc.).

The automatic adaptation function allows you to precisely determine the parameters of the motor connected to the inverter and adjust it. This function is important in cases where pump motors are replaced, when motor parameters change after repair, and when different types of electric motors are connected in series to the same converter.

The presence of this function reduces energy consumption by 3-5%, and when using refurbished electric motors, the savings reach 10%. The use of particularly high power frequency converters is associated with the generation of higher order harmonics.

The presence of higher harmonics in the current leads to overheating of the cable wires, increases the losses in the transformers, worsens the working conditions capacitor banks… In addition, the insulation of the elements of power networks ages prematurely, the elements of protective devices (automatic devices, fuses) are triggered unreasonably, interference occurs in telecommunication networks located near power cables.

Currently, many models of frequency converters are equipped with built-in electromagnetic compatibility (EMC) filters. In particular, to prevent higher current harmonics from entering the external supply network, VLT AQUA Drive frequency converters are equipped with chokes in the intermediate current link to reduce harmonic distortions.