The electric drive and its structure

Each electric actuator contains three components, namely:

-

Directly the engine;

-

Executive agency;

-

Transfer mechanism.

Accordingly, in order for the technological mechanism to perform its tasks precisely, all its components must perform some movements that can be carried out with the help of the drive.

What is an electric drive? — this is the main structural element of all technological units, the main function of which is to ensure the necessary movements of the executive body in accordance with a given law. For greater clarity, you can imagine a modern technological unit in the form of an integral set of drives that interact with each other and are connected by a single control system that ensures the necessary movements on different paths.

With the development of the industry, electric propulsion has taken a leading place both in production and in everyday life in terms of the number of motors and the total installed power.

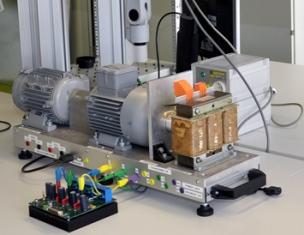

Any electric drive can be divided into a power unit (on it, the energy moves from the electric motor to the executive bodies), as well as the control system (provides the necessary movement according to the specified law). In addition, it includes three devices: control, transmission and conversion.

A transfer device includes couplings of connections, mechanical transmissions, which are necessary to transmit mechanical energy to the performing equipment, which is generated by an electric motor.

Converter designed to control the flow of electricity that comes from the network to regulate the operation of the electric motor. This is the power part of the control system.

A control mechanism is a low current information part of the control system that collects and processes input information. This information contains data about the current state of the system, as well as signals that are sent to electric motor units.

Currently, electric drives are being improved in terms of increasing their reliability, durability, performance, efficiency, high efficiency operation and reducing weight and size and specific properties. At each of the stages of technology improvement, obtaining the necessary results is accompanied by the development of the theoretical aspect of the matter.

Different types of electric drives are distinguished according to different parameters:

-

By type of movement: translational, rotational, reverse and unidirectional movement, and in addition, piston.

-

By type of mechanical transmission device: without gears and reducers.

-

By the method of transmission of energy of mechanical type: interconnected, individual and group.

-

According to the speed control method, as well as the position of the executive body: tracking, positional, adjustable and non-adjustable in terms of speed, adaptive, software controlled.

-

By type of electrical converter

Electric actuator — this is a device that is designed to shift the workpiece accordingly with the signals that come from the control unit.

Valves, gates, valves, throttle valves, guide vanes of any kind can act as working parts, which can affect changes in the amount of working substance or energy entering the control object.

The working bodies can move both rotationally and progressively, within the limits of a certain number of revolutions or one. With their participation, a direct impact is made on the subject being controlled. In most cases, the drive unit with an electric drive includes: a gearbox, the electric drive itself, a sensor for the indicator of the position of the limit switches, a feedback unit.