The use of wound rotor induction motors as part of a variable frequency drive

When upgrading crane electric drives, in order to reduce costs, it is rational to use existing and working crane asynchronous motors. The majority of domestic faucets are usually equipped with phase rotor motors of the MT and 4MT series.

When upgrading crane electric drives, in order to reduce costs, it is rational to use existing and working crane asynchronous motors. The majority of domestic faucets are usually equipped with phase rotor motors of the MT and 4MT series.

Of interest is the possibility of using crane asynchronous motors with a phase-locked rotor as part of a frequency-controlled electric drive. Currently, LLC «Cranpriborservice» has positive experience in the operation of asynchronous motors with a power of up to 55 kW with a short-circuited phase rotor when powered by frequency converters.

Such a technical solution was made during the modernization of cranes previously equipped with traditional crane drive systems based on an asynchronous motor with a phase rotor.In order to reduce the cost of such an upgrade, electric motors were saved, and in some cases ballast resistors, which, after checking the calculations and changing the connection scheme, were used as braking resistors.

From an energy point of view, the MT and 4MT series wound-rotor electric motors are even more preferable than the squirrel-cage electric motors of the same series, because they have a lower active resistance of the rotor winding and, therefore, lower losses in the copper of the rotor in equilibrium.

A wound-rotor electric motor selected for operation in a traditional crane system with an electric drive with rheostat regulation, when switching to power from a frequency converter (if the operating mode of the mechanism is not exceeded) always has a lower level of start-up losses.

In most cases, crane upgrades are performed to extend the speed control range for precise assembly operations or when transferring the crane to the floor. In this case, the operation mode of the crane, as a rule, is lower than that established during its manufacture. With vector control, steady-state losses are also reduced, as the power consumption in the electric drive is optimized at part load.

There is an opinion that the voltage pulses at pulse width modulationapplied to the motor windings leads to accelerated aging of the insulation. In this case, the use of "special electric motors for operation as part of variable frequency drives" is recommended.It is true that the insulation class of such electric motors does not differ from the insulation class of household electric motors of the MT and 4MT series. More than ten years of operation of phase rotor electric motors with short-circuited rings as part of a variable frequency drive has shown their high reliability.

A feature of the design of motors with a phase rotor is the presence of slip rings and brushes. Therefore, an open circuit of one of the rotor phases of such taps due to wear of the brushes or damage to the brush holder seems very likely.

In order to establish the operability of the electric drive in case of rotor phase loss, an experiment was carried out at the Cranpriborservice LLC stand with an electric drive of the lifting mechanism with a frequency converter of the Altivar 71 type and a 55 kW motor. The control law of the electric motor is vector. Before lifting a nominal load "from the weight", one of the short-circuited phases of the rotor of the 55 kW motor was disconnected.

The electric drive was then turned on in the uphill direction at a frequency of 25 Hz. At the same time, the electric drive accelerates in the direction of ascent, but fluctuations in speed are noticeable.

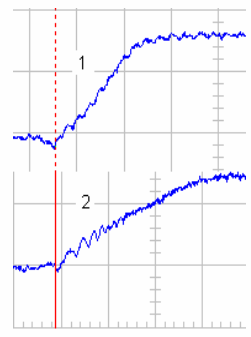

In fig. 1 shows the experimental oscillograms of the electric drive speed with the rotor short-circuited and when one of the phases in the rotor is disconnected.

Rice. 1. Experimental oscillograms of the speed of the electric drive when lifting the nominal load 0-3P: 1-rotor rings are short-circuited; 2. one of the rotor phases is disconnected.

From the oscillograms, it can be seen that the acceleration of the electric drive in the direction of ascent with a broken phase in the rotor lasts about 1.5 times longer than with fully shortened rings. However, from the point of view of protection against falling loads, such a regime is acceptable.

It should also be noted that the stator current measured by the converter during phase loss does not differ from the current in symmetrical mode, although theoretically its value should be higher. The thermal protection of the electric motor is based on the calculation of I2t, therefore its operation in this mode will not take place.

Thus, the loss of phase in the rotor may not be noticed by service personnel and the motor may be damaged by overheating. As protection against such a mode, it is possible to propose the inclusion of a thermal relay in the stator or rotor circuit, but this solution requires experimental verification.