What is servo, servo steering

A servo drive is a drive whose precise control is carried out through negative feedback and thus allows you to achieve the necessary parameters of the movement of the working body.

Mechanisms of this type have a sensor that monitors a specific parameter, for example speed, position or force, as well as a control unit (mechanical rods or an electronic circuit) whose task is to automatically maintain the required parameter during the operation of the device, depending on the signal from the sensor at any moment in time.

The initial value of the operating parameter is set using a control, for example potentiometer knob or by using another external system where a numerical value is entered. So, the servo drive automatically performs the assigned task — relying on the signal from the sensor, it precisely adjusts the set parameter and keeps it stable on the drive.

Many amplifiers and regulators with negative feedback can be called servos.For example, servo drives include braking and steering in cars, where a hand-operated amplifier necessarily has negative position feedback.

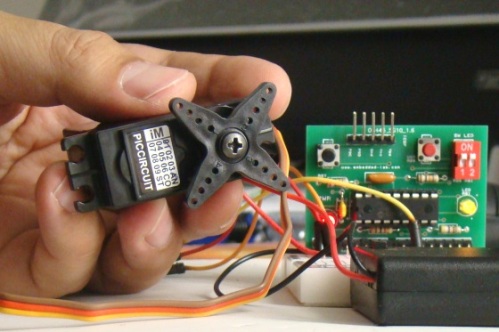

Main components of the servo:

-

Drive unit;

-

Sensor;

-

Control unit;

-

Converter.

For example, a pneumatic cylinder with a rod or an electric motor with a gearbox can be used as a drive. The feedback sensor can be encoder (angle sensor) or for example Hall sensor… Control unit — individual inverter, frequency converter, servo amplifier (English Servodrive). The control device can immediately include a control signal sensor (transducer, input, impact sensor).

In its simplest form, the control unit for an electric servo drive is based on a circuit for comparing the values of the set signals and the signal coming from the feedback sensor, as a result of which a voltage of the appropriate polarity is supplied to the electric motor.

If smooth acceleration or smooth deceleration is required to avoid dynamic overloads of the electric motor, then more complex control schemes based on microprocessors are applied, which can position the working body more precisely. So, for example, the device for positioning the heads in hard disks is arranged.

Precise control of groups or single servo drives is achieved by using CNC controllers, which by the way can be built on programmable logic controllers. Servo drives based on such controllers reach 15 kW of power and can develop a torque of up to 50 Nm.

Rotary servo drives are synchronous, with the possibility of extremely precise adjustment of rotation speed, rotation angle and acceleration, and asynchronous, where the speed is maintained very precisely even at extremely low speeds.

Synchronous servo motors are capable of accelerating very quickly to rated speed. Circular and flat linear servos are also common, allowing accelerations up to 70 m/s².

In general, servo devices are subdivided into electrohydromechanical and electromechanical. In the former, the movement is generated by the piston-cylinder system and the response is very high. The latter simply use an electric motor with a gearbox, but the performance is an order of magnitude lower.

The scope of application of servo drives today is very wide, due to the possibility of extremely accurate positioning of the working body.

There are mechanical locks, valves and working bodies of various tools and machine tools, especially with CNC, including automatic machines for the factory production of printed circuit boards and various industrial robots and many other precision tools. High speed servo motors are very popular with model aircraft. In particular, servo motors are notable for their characteristic uniformity of motion and efficiency in terms of energy consumption.

Three-pole commutator motors were originally used as drives for servo motors, where the rotor contained windings and the stator contained permanent magnets. It also had a collector brush. Later, the number of coils increased to five, and the torque became greater and the acceleration became faster.

The next stage of improvement — the windings were placed outside the magnets, so the weight of the rotor was reduced, and the acceleration time was reduced, but the cost increased. As a result, a key improvement step was taken — they abandoned the manifold (in particular, permanent magnet rotor motors became widespread) and the motor turned out to be brushless, even more efficient, since acceleration, speed and torque were now even higher.

Servo motors have become very popular in recent years. Controlled by Arduino, which opens wide possibilities for both amateur aviation and robotics (quadcopters, etc.), as well as for the creation of precision metal-cutting machines.

For the most part, conventional servo motors use three wires to operate. One of them is for power, the second is signal, the third is common. A control signal is supplied to the signal wire, according to which it is necessary to adjust the position of the output shaft. The position of the shaft is determined by the potentiometer circuit.

The controller, through resistance and the value of the control signal, determines in which direction it is necessary to turn in order for the shaft to reach the desired position. The higher the voltage removed from the potentiometer, the greater the torque.

Thanks to their high energy efficiency, precise control capabilities and excellent performance, servo drives based on brushless motors are increasingly found in toys, household appliances (heavy duty vacuum cleaners with HEPA filters) and industrial equipment.