How are induction motors different from synchronous motors?

In this article, we will look at the main differences between synchronous electric motors and induction motors so that anyone reading these lines can clearly understand these differences.

Asynchronous motors are more widespread today, but in some situations synchronous motors are more suitable, more effective for solving specific industrial and production problems, this will be discussed below.

First, let's recall what an electric motor is. Electrical motor is called an electric machine, designed to convert electrical energy into mechanical energy of rotation of the rotor and serves as a drive for some mechanism, for example, to drive a crane or a pump.

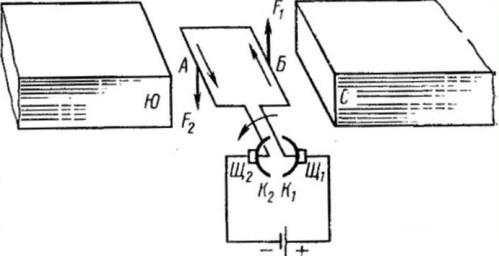

Back in school, everyone was told and shown how two magnets repel from the poles of the same name, and from the opposite poles - they attract. it permanent magnets… But there are also variable magnets. Everyone remembers a drawing with a conductive frame located between the poles of a permanent magnet in the shape of a horseshoe.

A horizontally located frame, if a direct current flows through it, will become the magnetic field of a permanent magnet under the action of a pair of forces (Ampere strength) until an upright equilibrium is reached.

If a direct current is then passed through the frame in the opposite direction, the frame will rotate further. As a result of such an alternating supply of the frame with direct current in one direction or another, a continuous rotation of the frame is achieved. The frame here is an analogue of a variable magnet.

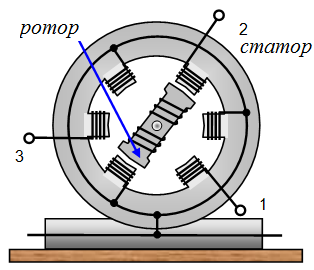

The above example with a rotating frame in its simplest form demonstrates the principle of operation of a synchronous electric motor. Each rotor synchronous motor has field windings that are supplied with direct current that forms the rotor's magnetic field. The stator of a synchronous electric motor contains a stator winding that forms the stator magnetic field.

When alternating current is applied to the stator winding, the rotor will rotate at a frequency corresponding to the frequency of the current in the stator winding. The speed of the rotor will be synchronous with the frequency of the stator winding current, which is why such an electric motor is called synchronous. The rotor magnetic field is generated by the current, not induced by the stator field, so the synchronous motor is able to maintain synchronous rated speed regardless of the load power, of course within reasonable limits.

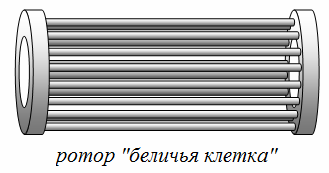

An induction motor, in turn, differs from a synchronous motor. If we recall the picture in the frame and the frame is simply short-circuited, then as the magnet rotates around the frame, the current induced in the frame will create a magnetic field on the frame and the frame will try to catch up with the magnet.

The speed of the frame under mechanical load will always be less than the speed of the magnet and therefore the frequency will not be synchronous. This simple example demonstrates how an induction motor works.

In an asynchronous electric motor, the rotating magnetic field is formed by an alternating current of the stator winding located in its channels. The rotor of a typical induction motor does not have windings as such, instead it has short-circuited bars (squirrel rotor), such a rotor is called a squirrel rotor. There are also phase rotor induction motors, where the rotor contains windings, the resistance and current in which can be controlled by a rheostat.

So what is the main difference between induction motor and synchronous motor? Outwardly, they are similar, sometimes even a specialist will not distinguish a synchronous electric motor from an asynchronous one by external characteristics. The main difference lies in the design of the rotors. The rotor of the induction motor is not supplied with current, and the poles on it are induced by the magnetic field of the stator.

The rotor of a synchronous motor has an independently driven field winding. The stators of a synchronous and asynchronous motor are arranged in the same way, the function in each case is the same - to create a rotating magnetic field on the stator.

The speed of an induction motor under load always lags behind the rotation of the stator magnetic field by the amount of slip, while the speed of the synchronous motor is equal in frequency to the "revolution" of the stator magnetic field, therefore, if the speed is to be constant under different loads , it is preferable to choose a synchronous motor, for example in The guillotine shear drive is best suited for its task by a powerful synchronous motor.

The field of application of asynchronous motors today is very wide. These are all kinds of machines, conveyors, fans, pumps — all that equipment where the load is relatively stable or the reduction in load speed is not critical to the work process.

Some compressors and pumps require constant speed at any load; synchronous motors are installed on such equipment.

Synchronous motors are more expensive to manufacture than asynchronous motors, so if there is a choice and a slight reduction in speed under load is not critical, they acquire an asynchronous motor.

Synchronous electric motors are widely used in electric drives that do not require speed control. Compared to asynchronous motors, they have a number of advantages:

-

higher efficiency;

-

the possibility of producing engines with a low rotational speed, which makes it possible to abandon intermediate gears between the engine and the working machine;

-

engine speed does not depend on its shaft load;

-

the possibility of using reactive power as compensating devices.

Synchronous electric motors can be consumers and generators reactive power... The nature and value of the reactive power of a synchronous motor depends on the magnitude of the current in the field winding. The dependence of the current in the winding supplying voltage to the electrical network on the excitation current is called the U-shaped characteristic of a synchronous motor. At 100% motor shaft load, its cosine phi equals 1. In this case, the electric motor does not consume reactive power from the electrical network. In this case, the current in the stator winding has a minimum value.