Selection of electric motors for equipment with different types of load and operating modes

The correct selection of electric motors for production mechanisms ensures their continuous and reliable operation throughout the standard service life. This is a very important process where many different factors and criteria have to be considered. One of the most important factors is the consideration of the nature and type of the load.

The correct selection of electric motors for production mechanisms ensures their continuous and reliable operation throughout the standard service life. This is a very important process where many different factors and criteria have to be considered. One of the most important factors is the consideration of the nature and type of the load.

Here are all the criteria to consider when choosing: How to choose the right electric motor

When choosing electric motors for various machines, installations and machines, it is necessary to take into account the different types of load, the type of mechanical characteristics, the nature and duration of the work cycles of these mechanisms.

Knowing how the load on the shaft of the selected electric motor will change, it is possible to accurately determine how the power losses will change during operation, and thanks to this, choose an electric motor that, working at a given load, will not overheat. The maximum heating temperature of the insulation of the electric motor will not exceed the permissible value during the entire working cycle.

Incorrect selection of electric motors of production mechanisms leads to disruption of production processes and leads to losses of manufactured products and additional electricity costs.

Electrical equipment with electric motors must fully meet the requirements of the technological process.

The choice of one of the catalog types of electric motors is considered correct if the following conditions are met:

-

the most complete correspondence of the electric motor with the working machine (drive mechanism) in terms of mechanical properties. This means that the electric motor must have such a mechanical characteristic that it can provide the drive with the necessary values of speed and acceleration in a stationary and transient state;

-

maximum use of electric motor power in all operating modes. The temperature of all active parts of the electric motor in the most severe operating modes should be as close as possible to the permissible heating temperature, but not exceed it;

-

compatibility of the electric motor with the drive and environmental conditions in terms of design;

-

compliance of the electric motor with the parameters of the power supply.

To choose an electric motor, the following data is required:

-

type and name of the drive mechanism;

-

maximum shaft power, if the operating mode is continuous and the load is constant, and in other cases, graphs of changes in power or moment of resistance of the shaft as a function of time;

-

rotational frequency (or rotational frequency range) of the drive shaft;

-

method of articulation of the drive mechanism with the shaft of the electric motor (in the presence of kinematic transmissions, the type of transmission and the gear ratio are indicated);

-

the amount of starting torque the electric motor must provide to the drive shaft;

-

speed regulation limits (upper and lower values and corresponding power and torque values);

-

required quality (smoothness, gradation) of speed control;

-

frequency of activation of the drive within an hour;

-

characteristics of the external environment.

The selection of an electric motor based on consideration of all conditions and nominal data is carried out according to catalogs.

The possible modes of operation of electric drives are distinguished by a huge variety in terms of the nature and duration of cycles, load values, cooling conditions, the ratio of starting losses and smooth running, etc., therefore the production of electric motors for each of the possible modes of operation of an electric drive makes no practical sense.

Based on the analysis of real modes, a special class of modes is identified — nominal modes, for which serial engines are designed and manufactured.

The data contained in the passport of an electric machine refers to a certain nominal mode and is called the nominal data of an electric machine.

Manufacturers guarantee that when the electric motor operates in rated mode at rated load, it is fully utilized thermally.

The current GOST provides 8 nominal modes, which in accordance with the international classification have symbols S1 — S8.

Continuous duty S1 — operation of the machine at a constant load for a long enough time to achieve a constant temperature of all its parts.

Short-term duty S2 — operation of the machine at a constant load for a time insufficient for all parts of the machine to reach the set temperature, followed by stopping the machine for a time sufficient to cool the machine to a temperature not more than 2 ° C from the ambient temperature . For short-term work, the duration of the work period is 15, 30, 60, 90 minutes.

Intermittent duty S3 — a sequence of identical duty cycles, each of which includes the time of continuous load operation during which the machine does not heat up to the set temperature and the parking time during which the machine does not cool down to the ambient temperature.

In this mode, the duty cycle is such that the inrush current does not significantly affect the temperature rise. The cycle time is insufficient to achieve thermal equilibrium and does not exceed 10 minutes. The mode is characterized by the value of the duration of inclusion in percentages:

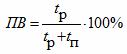

Motors produced by the industry for this mode of operation are characterized by a duty cycle (PV), which is defined by the duration of one duty cycle

where tp is the engine running time; tp — pause time.

Standardized values of the duration of inclusion: 15, 25, 40, 60% or relative values of the duration of the working period: 0.15; 0.25; 0.40; 0.60. For S3 mode, the rated data only corresponds to a certain duty cycle and refers to the duty period.

Modes S1 — S3 are currently the main ones, the nominal data for which are included by the local electric vehicle factories in the catalogs and passport of the machine.

Read more about it here: Operating modes of electric motors

For a reasonable motor selection in terms of power, it is necessary to know how the motor shaft load changes over time, which in turn makes it possible to assess the nature of the change in power losses.

In addition, it is necessary to establish how the process of heating the engine proceeds as a result of the release of energy losses in it. This approach allows you to choose the motor in such a way that the maximum temperature of the winding insulation does not exceed the permissible value. This condition is one of the main ones for ensuring the reliable operation of the engine throughout its service life.

The choice of the power of the electric motor must be made in accordance with the nature of the loads on the working machine. This character is assessed on two grounds:

-

according to the nominal mode of operation;

-

through changes in the amount of energy consumed.

Engine power must meet three conditions:

-

normal heating during operation;

-

sufficient overload capacity;

-

sufficient starting torque.

The choice of electric motors with the so-called"Power reserve", based on the largest possible load according to the schedule, leads to underutilization of the electric motor, and therefore to increased capital costs and operating costs due to reduced power factors and efficiency. Excessive increase in engine power can also lead to jerks during acceleration.

If the electric motor must work for a long time with a constant or slightly changing load, then determining its power is not difficult and is carried out according to the formulas. It is much more difficult to choose the power of electric motors in other modes of operation.

The short-term load is characterized by the fact that the periods of inclusion are short, and the breaks are sufficient for the complete cooling of the electric motor. In this case, it is assumed that the load on the electric motor during the switching periods remains constant or almost constant.

In order for the electric motor to be used correctly for heating in this mode, it is necessary to choose it so that its continuous power (indicated in the catalogs) is less than the power corresponding to the short-term load, i.e. the electric motor has a thermal overload during the periods of its short-term operation...

If the periods of operation of the electric motor are significantly less than the time required for its complete heating, but the pauses between the periods of switching on are significantly shorter than the time of complete cooling, then there is repeated short-term loading.

Power calculation and motor selection for continuous operation

With a constant or slightly varying shaft load, the motor power should only slightly exceed the load power.In this case, the condition must be met

Pn ≥ P,

where Pn is the rated engine power; P — load power. Choosing an engine comes down to choosing it from the catalog.

Selection of engine power for continuous operation. If the torque and power of the production mechanism do not change, then a motor with a nominal power Pn equal to the power of the load should be selected, taking into account losses in the transmission (gearbox):

Pn ≥ Pm /ηt, W

where ηt is the transmission (gearbox) efficiency.

At a given moment of resistance of the drive mechanism Ms, N ∙ m and the frequency of rotation of the output shaft of the gearbox n2, rpm

Pm = Mc ∙ ω2, W

where ω2 = 2π ∙ n2 / 60, rad / s

For some production mechanisms operating in a continuous mode with a constant moment of shaft resistance, there are approximate formulas for determining the power of motors.

Power calculation and motor selection for short term load

Motors for short-term operation of the electric drive are selected according to their rated power, which must be equal to the load power, taking into account the duration of operation. Standard allowable values for engines produced by the industry for short-term operation are 10, 30, 60, 90 minutes.

In the absence of intermittent duty motors, intermittent duty motors can be installed. In this case, a run time of 30 minutes corresponds to duty cycle = 15%, 60 minutes corresponds to duty cycle = 25%, and 90 minutes corresponds to duty cycle = 40%.As a last resort, it is possible to use engines for continuous operation with Pn < P and their subsequent checking for thermal conditions.

Power calculation and motor selection for intermittent load

For an electric drive operating in intermittent mode, the motor power is calculated using the average loss method or equivalent values. The first method is more accurate, but more labor-intensive. It is more convenient to use the method of equivalent values. Depending on the given load schedule P = f (t), M = f (t), I = f (t), the mean square values are determined, which are called equivalent.

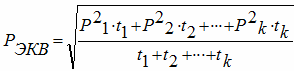

Equivalent power is the RMS power of the load diagram

where t1, t2, …, tk — time intervals in which the load power is equal to P1, P2, …, Pk, respectively.

According to the catalog, for the obtained values of Reqv and PV, the motor rated power is selected from the condition Pn ≥ REKV.

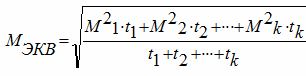

If the diagram M = f (t) is given, then the equivalent moment

and the equivalent power at speed n is given by the expression

Req = Meq • n / 9550 (kW).

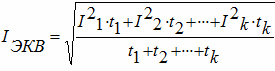

If the diagram I = f (t) is given, the current of the heating equivalent

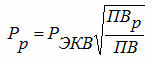

The calculated value of PVr often differs from the standard values, therefore either the obtained value of PVr is rounded to the nearest standard value, or the equivalent power is recalculated using the formula

During operation, short-term overloads are observed that exceed the nominal power of the motor. They do not significantly affect the heating of the engines, but can lead to incorrect operation or stalling. Therefore, the motor should be checked for overload capacity according to the expression

Pm / Pn = ku ∙ Mm / Mn,

where Pm is the highest power in the load diagram; Mm / Mn — the multiple of the maximum torque is determined by the catalog; coefficient ku = 0.8 takes into account the possible voltage drop in the network.

If this condition is not met, then a motor with a higher power must be selected from the catalog and again checked for overload capacity.

See also on this topic: Selection of an engine for intermittent operation

The industry produces a number of series of intermittent load motors:

-

asynchronous cranes with a squirrel rotor in the MTKF series and with a phase rotor in the MTF series;

-

similar metallurgical series MTKN and MTN;

-

DC series D.

The machines of the specified series are characterized by the shape of an elongated rotor (anchor), which provides a reduction in the moment of inertia. In order to reduce the losses released in the stator winding during transients, motors of the MTKF and MTKN series have an increased nominal slip snom = 7 ÷ 12%. The overload capacity of the motors of the crane and metallurgical series is 2.3 — 3 at duty cycle = 40%, which at duty cycle = 100% corresponds to λ = Mcr / Mnom100 = 4.4-5.5.