What is the difference between a servo drive and a stepper motor

Stepper motor

The stepper motor belongs to the class of synchronous electric machines. Its stator contains several pole projections, each with an individual field winding. The rotor of a stepper motor is equipped with distinct magnetic poles, as a rule, these are permanent magnets fixed on a movable shaft or cylinder so that they can very precisely interact with the stator poles excited by the winding currents. The poles of the stator can be magnetized at a certain frequency, their excitation is carried out by applying pulses to the corresponding windings.

Thus, in order to obtain a certain angular speed of rotation of the rotor from the stepper motor, pulses of a certain frequency and duration are sequentially supplied to the stator windings, and the position of the working body is tracked only indirectly, by the number of "steps", because the magnets are expected to follow the poles...

We can say that the stepper motor is the best brushless motor option for those applications where it is necessary to precisely set the angular velocity of the rotor, but the accuracy of the position itself is not extremely critical. Because if for some external reason during the rotation of the rotor its physical deceleration occurs, then the pulses, although they will be delivered in the necessary amount and with the right parameters, expecting a certain result, in fact, their «effective amount» will be more - little and the controlled worker body will probably not be in the right position. However, a stepper motor is suitable for a vacuum cleaner or a quadcopter.

Servo

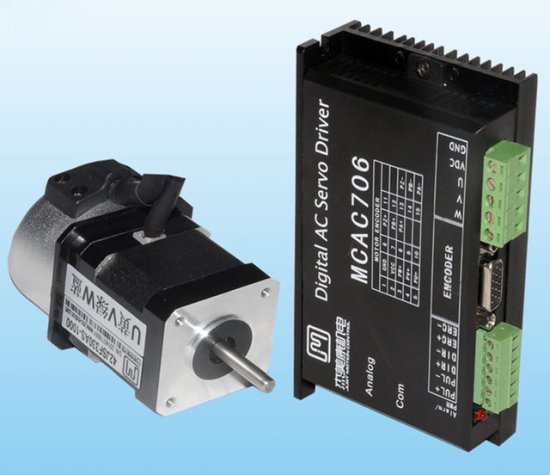

A servo drive is also a synchronous electric machine, but fundamentally more accurate than a stepper motor. Therefore, a servo drive is called a drive, not just a motor (servo means servo), because it necessarily includes not only a motor (for example, the same stepper motor), but also a process control and monitoring circuit. A mandatory component of the servo is the sensor for the position of the working body, in some cases — the rotor. For example, in CNC machines, a servo drive is needed to control the position of the work tool.

The servo has a feedback system for position, shaft rotation angle, etc. ), then the servo is guided by the direct result, on the real (not theoretical!) position of the working body. Depending on the current state, the logic circuit makes an adjustment regardless of whether the rotor has slipped, whether there has been backlash, or, say, whether the moving part of the machine has caught on some object.

Main practical differences

-

The servo drive is able to accelerate very intensively due to the possibility of changing the current of the field coils. The stepper motor picks up speed much more slowly.

-

The servo torque is adjustable and can be increased as the speed increases. Stepper motor torque drops at increased speed.

-

In a servo drive, the field winding current is proportional to the load, while a stepper motor initially has significant torque limitations.

-

A stepper motor does not imply position correction and a servo is more flexible in this regard.

-

A servo drive can be positioned very precisely (e.g. via an encoder) and a stepper motor is positioned only indirectly.

-

A servo requires a more careful approach to the design and tuning of the control circuit, especially in terms of safety, because if the stepper motor has a stuck shaft, it will simply start skipping steps, and the servo motor can start hard, increase the current and in resulting in burns or damage to the operating mechanism.