What is a variable speed electric drive for?

The consumption of any energy should be as efficient and appropriate as possible. This statement is unlikely to raise doubts. This is especially true for electrical energy, which today is the main resource in the national economy and industry.

Solving the problem of energy saving on a national scale will lead to significant preservation of many material resources in agriculture, industrial production, in the communal sphere and will have a positive impact on the ecology of the country.

One of the main consumers of electrical energy in many areas is movement powered by electricity, and if the economy of energy increases through more efficient management of it, through more competent consumption of mechanical and electrical energy in various technological processes, then the problem will be solved to a large extent.

The main way to solve this problem is to introduce variable speed electric drive where possible: conveyor belts, water supply pumps, ventilation systems, compressors, etc.Hardening of parts from different assortments.

Needless to say about transportation, public water supply and ventilation systems, which at different times of the day would do well to adjust according to current needs, rather than running the propulsion engines at full power all the time. The ventilation system, for example, can work less intensively at night and more intensively during the day.

Take, for example, a pump that pumps water into a water line. Different amounts of water are consumed in residential buildings at different times of the day. Consumption peaks, as you know, occur in the morning and evening hours, while during the day water consumption is half as much, and at night - 8 times less than in the morning and evening.

The water consumption of the system is proportional to the rotation speed of the pump drive, the water pressure in the system is proportional to the square of the rotation speed of the drive, and the power consumption of the drive motor is proportional to the cube of its rotation speed.

This means that the lower the rotation speed and the lower the pressure, the greater the energy savings. It obviously makes sense to reduce the head by reducing the rotation speed of the drive at night and during the day, this will provide very noticeable energy savings.

So, if the energy consumption of the pump motor of the domestic water supply system is proportional to the pressure and water flow at the same time, then how many times the pressure will be reduced, with a constant water flow, the same amount of energy will be consumed.

Practical examples of the application of such an idea show that energy savings reach 50%, in addition, water leaks in the system due to excess pressure and excess pressure are reduced to 20%. And all residents need is to install a frequency converter.

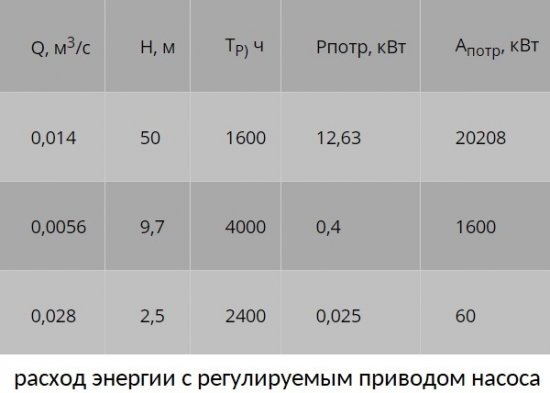

Let's do an approximate typical calculation, omitting all formulas related to hydraulics. Suppose there is a pump in standard mode, providing a head H = 50 m. The nominal flow rate of the liquid Q = 0.014 cubic meters / s, while the efficiency of the pump is n = 0.63.

Let the pump run at a flow rate of 1 * Q for 1600 hours, at a flow rate of 0.4 * Q for 4000 hours, and at a flow rate of 0.2 * Q for 2400 hours. Then, with a real electric motor with an efficiency of, say, 88%, the pump consumption will be approximately 52,000 kWh of electricity.

That is if you don't change the pressure. If we change the pressure in accordance with the current flow by reducing the engine speed, then the consumption of the same engine will be only 22,000 kWh. You save more than half!

The use of frequency converters in adjustable electric drive:

Frequency regulation of an asynchronous motor

Frequency converter - types, principle of operation, connection schemes

Differences between frequency converters and motor soft starters