Modern brushless DC motors

Thanks to significant advances in semiconductor electronics and the technology to create powerful neodymium magnets, brushless DC motors are widely used today. They are used in washing machines, vacuum cleaners, fans, drones, etc.

And although the idea of the principle of operation of a brushless motor was expressed as early as the beginning of the 19th century, it waited in the wings until the beginning of the semiconductor era, when the technologies became ready for the practical implementation of this interesting and efficient concept, which allowed brushless direct current motors to walk as widely as they do today. …

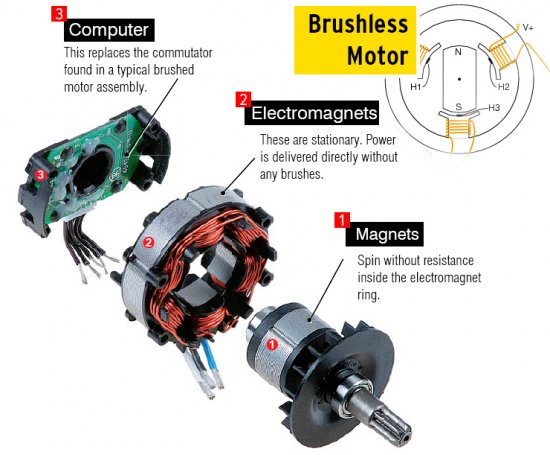

In the English version, they are called engines of this type BLDC Motor — Brushless DC motors — brushless DC motor. The motor rotor contains permanent magnets, and the working windings are located on the stator, that is, the BLDC motor device is completely opposite to what is in the classic brushed motor. The BLDC motor is controlled by an electronic controller called ESC — Electronic Speed Controller — electronic cruise control.

Electronic regulator and high efficiency

The electronic regulator allows the electrical energy supplied to the brushless motor to be smoothly varied. Unlike simpler versions of resistive speed governors, which simply limit power by connecting a resistive load in series with the motor, which converts excess power into heat, electronic speed control provides significantly higher efficiency without wasting the electrical power delivered. energy for unnecessary heating. ..

Brushless DC motor can be classified as self-synchronizing synchronous motor, where a sparking node requiring regular maintenance is completely turned off — collector… The function of the collector is taken over by the electronics, due to which the whole design of the product is greatly simplified and becomes more compact.

The brushes are actually replaced by electronic switches, the losses in which are much smaller than they would be with mechanical switching. Powerful neodymium magnets on the rotor allow for greater torque on the shaft. And such an engine heats up less than its collector predecessor.

As a result, the efficiency of the engine is the best, and the power per kilogram of weight is higher, plus a fairly wide range of rotor speed regulation and almost complete absence of generated radio interference. Structurally, engines of this type are easily adapted to work in water and in aggressive environments.

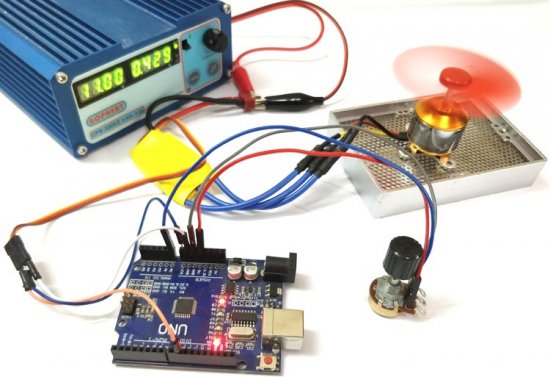

The electronic control unit is a very important and expensive part of a brushless DC motor, but it cannot be dispensed with.From this device, the engine receives power, the parameters of which simultaneously affect both the speed and the power that the engine will be able to develop under load.

Even if the rotation speed does not need to be adjusted, an electronic control unit is still needed, because it not only carries the control function, but also has a power supply component. We can say that ESC is an analogue of frequency controller for asynchronous AC motorsspecially designed for powering and controlling brushless DC motor.

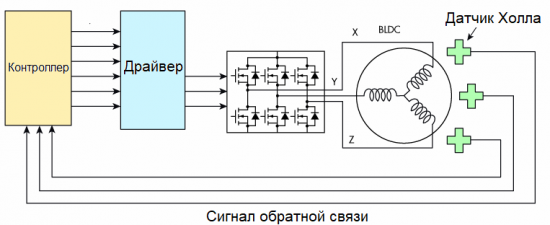

BLDC motor control

To understand how a BLDC motor is controlled, let's first remember how a commutator motor works. At its core the principle of rotation of the frame with a current in a magnetic field.

Each time the frame with the current rotates and finds an equilibrium position, the commutator (the brushes pressed against the collector) changes the direction of the current through the frame and the frame continues. This process is repeated as the frame moves from pole to pole. Only in the collector motor there are many such frames and there are several pairs of magnetic poles, which is why the brush collector contains not two contacts, but many.

ECM does the same. It reverses the polarity of the magnetic field as soon as the rotor has to turn away from the equilibrium position. Only the control voltage is not supplied to the rotor, but to the stator windings, and this is done with the help of semiconductor switches at the right time (rotor phases).

It is obvious that the current to the stator windings of a brushless motor must be supplied at the correct time, that is, when the rotor is in a certain known position. To do this, use one of the following methods.The first is based on the rotor position sensor, the second is by measuring the EMF of one of the coils that is not currently receiving power.

The sensors are different, magnetic and optical, the most popular are magnetic sensors Hall effect… The second method (based on EMF measurement), although effective, does not allow precise control at low speeds and at start-up. Hall sensors, on the other hand, provide more precise control in all modes. There are three such sensors in three-phase BLDC motors.

Motors without rotor position sensors are applicable in cases where the motor starts without a shaft load (fan, propeller, etc.). If starting is done under load, a motor with rotor position sensors is required. Both options have their pros and cons.

A solution with a sensor turns into a more convenient control, but if at least one of the sensors fails, the engine will have to be disassembled, in addition, the sensors require separate wires. In the sensorless version, no special wires are needed, but during start-up the rotor will swing back and forth. If this is unacceptable, it is necessary to install sensors in the system.

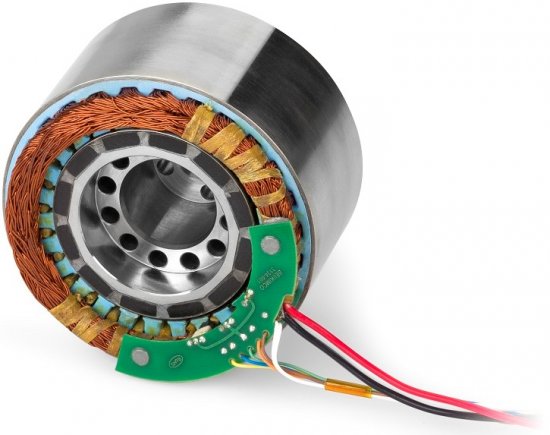

Rotor and stator, number of phases

The rotor of a BLDC motor can be external or internal and the stator internal or external respectively. The stator is made of magnetically conductive material, with the number of teeth completely divided by the number of phases. The rotor may be made, not necessarily of a magnetically conductive material, but necessarily with magnets firmly attached to it.

The stronger the magnets, the greater the available torque. The number of stator teeth should not be equal to the number of rotor magnets.The minimum number of teeth is equal to the number of control phases.

Most modern brushless DC motors are three-phase, simply for simplicity of design and control. As in AC induction motors, the windings of the three phases are connected here to the stator by a "delta" or "star".

Such motors without rotor position sensors have 3 power wires, and motors with sensors have 8 wires: two additional wires for powering the sensors and three for the signal outputs of the sensors.

Low-speed external rotor motors are made with a large number of poles (and therefore teeth) per phase to obtain rotation with an angular frequency significantly less than the frequency of the control current. But even with high-speed three-phase motors, the number of teeth less than 9 is usually not used.