Types of gear motors in electric drive

In electric drives for various purposes, in connection with many areas of modern industry, gear motors are widely used. These are special drive units that include an electric motor and a gearbox. This solution proves to be very useful and effective in automation, control and regulation systems, as well as in medical technology and many other specialized fields.

In practice, gear motors can be found today on industrial equipment for a variety of purposes. Cylindrical and planetary gearboxes are more common in industry, simply because of the convenient relative position of the output shaft of the gearbox and the electric motor.

The gearbox in its usual form is a monobloc, which is a combination of a gearbox and an electric motor. In this case, the electric motor and the gearbox are enclosed in a housing together with other parts of one mechanism.

The housing can be cast iron, metal or made of a lighter alloy, depending on the purpose and field of application of the drive. Due to its compact design, the installation of this drive unit is quite simple and usually does not require much effort.

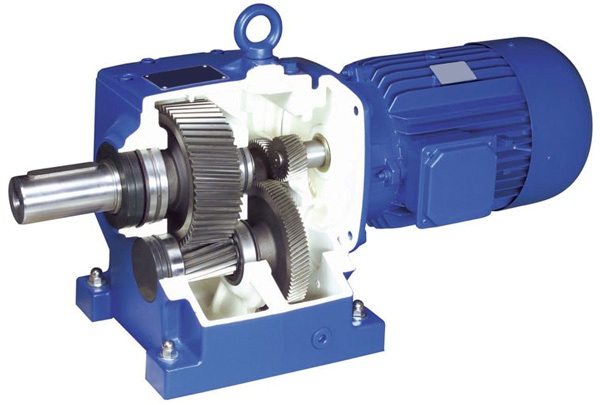

The part of the unit, which is itself a gearbox, in its simplest form includes shafts with gears resting on bearings. To obtain the required range of gear ratios, single-stage, two-stage, three-stage and four-stage motors with a reduction gear are used.

The construction of a geared motor can be easily understood by considering an example of a geared cylindrical two-stage unit. The drive gear of the first stage is fixed directly to the shaft of the electric motor. In this case, the same shaft also protrudes as the gearbox input shaft. The torque is transmitted from the drive gear to the gear shaft with the gear block, and then to the output shaft gear.

Thus, in the end, the working element of the equipment on which this reducer is mounted is also set in motion. A single-stage geared motor is even simpler: there is only a pair of shafts in the crankcase of the device, and only one gear is mounted on each.

The standard gear motor design involves pre-priming the unit with dip paint and then an air-dried alkyd enamel coating (usually blue or grey). For extreme operating conditions and for outdoor installation, special coatings for motor gearboxes are used.

In general, units of this type are suitable for operation in temperate climates.The main advantage of the gear motor is high efficiency, easy installation and minimal maintenance costs.

Today, there are four main types of gearboxes used in an electric motor housing: cylindrical, worm, wave and planetary. Let's take a closer look at each of these types.

Gear motors are the most popular in modern technology and industry. Units of this type allow to achieve an efficiency of over 90%, are distinguished by extremely slow wear of their structural elements and show high efficiency even under the most difficult conditions.

The cylindrical geared motor can work for a long time and even around the clock, powered by a regular network with a current frequency of 50 Hz, capable of providing the drive with the necessary power.

The gearbox shaft can be rotated in any direction, ensuring constant high efficiency at different operating speeds. Helical gear motors are affordable and their application is always economically justified. The installation always comes out quickly and conveniently.

The optimal solution for mechanisms operating in intermittent or continuous mode is the worm motor. The drive itself is unpretentious in maintenance, and the device is very easy to install, which is why it enjoys well-deserved popularity. In addition, a very wide range of gear ratios is achieved here — up to 100. The worm motor makes minimal noise during operation, while it is characterized by low vibrations.

An important feature of the worm gearbox is its characteristic self-locking ability.Lifting a load with a worm gearbox, you can be sure that in the event of a breakdown of the electric motor or simply when it suddenly stops, the gearbox will stop firmly at one point and the load will not fall, and therefore they will definitely not be damaged.

Optionally, the worm gear shaft can be rotated in any direction, which is extremely important when lifting in any field, from construction to transportation. For any lifting and conveyor systems, this worm motor option will be very useful.

Spur gear motors are considered to be one of the most high-tech and advanced powertrains of their kind. Wave transmission combines the proven reliability of a gear with the dynamics of flexible elements.

The wave gear motor is generally applicable in any field of industry, as it is always compact, light and allows you to get high gear ratios despite the small number of moving parts.

The unit is easily sealed by physically separating the drive motor, which makes it possible to use this type of gearbox even in workshops with increased dust and in conditions of high risk of explosion.

The surge reducer is capable of operating efficiently at any load (both low and high) within its rating, under both low and high pressure conditions. The unit is characterized by smooth running and high accuracy available for the driven machine.

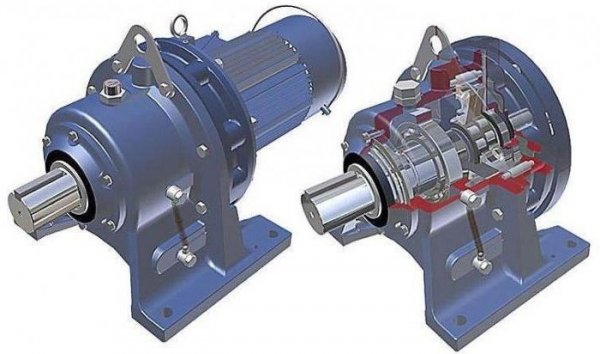

The optimal operation of the machine will be ensured by a planetary gearbox, characterized by a coaxial arrangement of the motor and the drive.The planetary unit differs from other types of gearboxes with its lightest weight and greater compactness with high performance characteristics.

These characteristics determine the use of a planetary gearbox, for example, in the design of wipers for cars. This solution makes it safe in case of uneven load on the gearbox shaft during the entire period of its operation from the moment of starting to stopping. Shaft loading can be direct or reversible for 8 to 24 hours of continuous operation.

The planetary gearbox is suitable for low pressure operation and can work with high precision equipment. Suitable for operation in all weather conditions, even in high humidity, you just need to adjust the motor accordingly.