Speed control of parallel excitation motors

Rotation frequency DC motors can be changed in three ways: by changing the resistance of the r -th armature circuit, changing the magnetic flux Ф, changing the voltage U supplied to the motor.

Rotation frequency DC motors can be changed in three ways: by changing the resistance of the r -th armature circuit, changing the magnetic flux Ф, changing the voltage U supplied to the motor.

The first method is rarely used, because it is uneconomical, allows to control the speed of rotation only under load and forces the use of mechanical characteristics with different slopes. When controlled in this way, the torque limit is kept constant. The magnetic flux does not change and assuming approximately this amperage, determined by the long-term allowable engine heating, is the same at all speeds, then the maximum allowable torque must also be the same at all revs.

Speed regulation DC motors with parallel excitation change in the magnetic flux has gained considerable popularity. The flow can be changed with a rheostat. As the resistance of this rheostat increases, the excitation current and magnetic flux decrease and the rotation frequency increases.Each reduced value of the magnetic flux Ф corresponds to increased values of n0 and b.

So with the weakening of the magnetic flux mechanical characteristics are straight lines located above the natural feature, not parallel to it, and with greater slope, the smaller flows correspond. Their number depends on the number of rheostat contacts and can be quite large. In this way, the regulation of the rotation speed by weakening the flux can be made practically stepless.

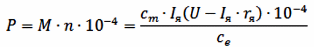

If, as before, we assume that the maximum permissible amperage at all speeds is the same, then P = const

Therefore, when adjusting the speed by changing the magnetic flux, the maximum permissible power of the motor remains constant at all speeds. The torque limit changes in proportion to the speed. As the engine speed increases, the weakening of the field increases the spark under the brushes due to an increase in the reactive e. and others. with induced in the involved sections of the engine.

When the motor is running at reduced flux, the stability of operation is reduced, especially when the load on the motor shaft is variable. At a small value of the flux, a demagnetizing effect of the armature reaction is noticed. Since the demagnetization effect is determined by the magnitude of the armature current of the electric motor, then with changes in the load, the speed of the motor changes sharply. To increase the stability of operation, parallel-excited variable speed motors are usually supplied with a weak series field winding, the flux of which partially compensates for the demagnetizing effect of the armature reaction.

Engines designed to operate at higher speeds must have increased mechanical strength. At high speeds, engine vibration and operating noise increase. These reasons limit the maximum speed of the electric motor. The lower speed also has a certain practical limit.

Rated torque determines the size and cost of DC motors (as well as asynchronous motors). By reducing the smallest, in this case nominal, revolutions of the motor with a certain power, its rated torque will increase. This will increase the engine size.

In industrial enterprises, motors with adjustment ranges are most often used

To expand the range of speed regulation by changing the magnetic flux, a special motor excitation circuit is sometimes used, which makes it possible to improve the commutation and reduce the influence of the armature reaction at high engine speeds. The supply to the coils of the two pole pairs is split, forming two independent circuits: the coil circuit of one pole pair and the circuit of the other pair.

One of the circuits is connected to a constant voltage, in the other the magnitude and direction of the current change. With this inclusion, the total magnetic flux interacting with the armature can be changed from the sum of the highest values of the fluxes of the coils of the two circuits to their difference.

The coils are connected in such a way that the full magnetic flux always passes through one pair of poles. Therefore, the armature reaction affects to a lesser extent than when the magnetic flux of all poles is weakened.All multi-pole DC motors with a wave armature winding can thus be controlled. At the same time, stable operation of the engine is achieved in a significant range of speeds.

Controlling the speed of DC motors by changing the input voltage requires the use of special circuits.

DC motors compared to asynchronous motors are much heavier and several times more expensive. The efficiency of these engines is lower, and their operation is more complicated.

Industrial plants receive power from three-phase current and special converters are needed to obtain direct current. This is due to additional energy losses. The main reason for using direct current motors with parallel excitation to drive metal cutting machines is the possibility of practically stepless and economical regulation of their speed of rotation.

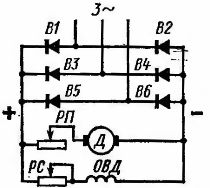

In mechanical engineering, complete drives with rectifiers and a parallel-excited DC motor are used (Fig. 1). Through the computer rheostat, the excitation current of the electric motor is changed, providing almost stepless regulation of its rotation speed in the range 2: 1. The drive set includes a starting rheostat RP, as well as protective equipment, in fig. 1 is not shown.

Rice. 1. Schematic of a DC drive with a rectifier

VThe transformer oil-immersed rectifiers (B1 — B6) and all equipment are placed in a control cabinet, and a computer rheostat is installed in a convenient service location.