Servicing of complete switchgear

KRUs are designed to receive and distribute AC electrical power at an industrial frequency. The use of switchgear allows you to refuse the installation of electrical equipment delivered to the construction site in bulk: all the equipment necessary for the circuit of the switchgear is installed in separate cabinets in specialized factories.

KRUs are designed to receive and distribute AC electrical power at an industrial frequency. The use of switchgear allows you to refuse the installation of electrical equipment delivered to the construction site in bulk: all the equipment necessary for the circuit of the switchgear is installed in separate cabinets in specialized factories.

Complete switchgear units (KRU) have a number of advantages over conventional ones distribution units (RU): technological in the industrial installation of substations, reliable in operation with proper operation, etc.

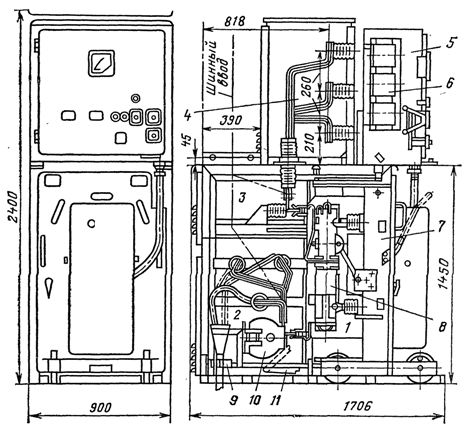

The structural feature of KRU (Fig. 1) and KRUN 6-10 kV (Fig. 2) is a metal cabinet, which is a frame metal structure. The cabinet is divided by metal partitions into compartments: busbars, pull-out trolley, disconnectable contacts, current transformers and cable assemblies, tool cabinet. Partitions in the cabinets are designed to locate possible accidents inside the cabinets and for easier maintenance.

In extendable cabinets, circuit breaker trolleys can occupy three positions:

-

operating where the circuit breaker cart is in the cabinet, the primary and secondary circuit contacts are closed, the circuit breaker is under load or energized if open,

-

control when the cart with the circuit breaker is not completely removed from the cabinet, the contacts of the primary circuit are open and the secondary ones remain closed (in this position it is possible to test the circuit breaker for opening and closing).

-

repair, in which the cart with the switch is completely pumped out of the cabinet, the contacts of all circuits are open.

Rice. 1. Cabinet of the K-XII series with a VMC -10 circuit breaker: 1 compartment of a pull-out trolley, 2 — compartment for current transformers and cable seals, 3 — compartment of upper (busbar) disconnecting contacts, 4 — compartment for busbars, 5 - tool cabinet, b -relay compartment, 7 -trolley, 8 — circuit breaker VMP -10 with drive PE -11, 9 — current transformer with zero sequence, 10 — current transformer, 11 — earthing

Rice. 2. Complete switchgear of the K-37 series. Section through the outlet cage with air outlet: 1 — compartment for retractable trolley, 2 — compartment for disconnecting contacts, current transformers, earthing, 3 — compartment for busbars, 4 — relay cabinet, 5 — trolley with switch, 6 — ventilation .

The main device of the switchgear, which affects its reliability, is the retractable element, in which most of the listed locks are assembled. Unclear operation of the slider lock can cause the latter to fail to deploy with the switch on.If the difference between the retainer and the lever resting on it will be more than the allowable, deformation or breakage of the retainer may occur. The clear fixation of the sliding element in the working position indicates the correct articulation of the main detachable contacts, and if the adjustment of the finishing mechanism is disturbed, the moving contacts may not reach the fixed ones.

During repairs, to protect personnel from accidental contact with live parts that are under voltage, the cabinets are equipped with a blocking system:

-

when rolling the cart out of the cabinet, access to live parts is automatically closed by protective covers,

-

operational blocking, which excludes wrong operations: pushing the trolley out of the working and control position when the switch is on,

-

closing the earthing switch if the circuit breaker trolley is in the operating position,

-

rolling the cart into the cabinet with the grounder on.

In the event of a failure of the earthing disconnector to be blocked, the withdrawable element can be installed in the operating position with the disconnector and the switch on at the same time. Failure of safety covers and the drive of the cover mechanism can result in the fact that a worker inside the retractable element compartment is energized if the covers are not fully closed when the retractable element is deployed, are not padlocked . etc.

Complete switchgear works reliably with proper cabinet installation, high-quality commissioning and equipment setup.An important factor for the reliable operation of the reactor installation is their correct operation, compliance with all manufacturers' recommendations for the operation of the reactor installation. Failure to comply with the listed requirements can lead to damage and accidents in the distribution system.

The presence of holes in the partitions reduces the localization ability of the distribution and distribution devices. In the event of a short circuit in the terminations of the cables, in case of damage to the circuit breakers, overlapping of the insulation, the electric arc can pass through the openings to the busbars and equipment of the neighboring cells.

Poor sealing of cabinets can lead to moisture and dust entering the cabinets causing insulation to overlap, warping during cabinet assembly results in failure of primary disconnect contacts and support insulators when carts roll into cabinets, poor adjustment and defects in locking mechanisms lead to wrong actions by personnel during switching.

When inspecting KRU, KRUN, attention should be paid to the quality of the sealing of doors, bottoms in the places of cable passage, the absence of cracks in the joints of cabinets through which small animals can penetrate.

The operation of the lighting and heating network (in the cold season) of cabinets and rooms, the oil level in the switches, the absence of visible damage to the insulators, the condition of the relay equipment and secondary circuits, the presence of clear inscriptions on the cabinets are checked. Coronation of insulators is checked at night. Equipment checks are carried out through observation windows, hatches, mesh fences.

In case of sudden changes in the temperature of the outside air, the relative humidity in the cabinets increases (up to 100%) and the insulators become humidified. Overlapping of the insulators may occur on a damp and dusty surface. For reliable operation of the insulation, it is necessary to periodically clean it.

One of the effective ways to protect the insulation is to coat the insulators with a hydrophobic paste. In addition, to ensure the normal operation of the cabinets in conditions of dew loss, face seam seals are additionally provided, support and sleeve insulators are used with a discharge path length above the surface of the insulator at least 165 mm, and automatic devices :

-

turning on the heating of the oil switches at temperatures below — 25 ° C,

-

activation of forced heating of cabinets at temperatures below + 5 ° C for accelerated drying of the insulation and prevention of dew loss on the insulation at relative humidity above 70%,

-

heating devices and relay equipment at temperatures below +5 ° C.

Recently, in order to reduce the severity of the damage that occurred during a short circuit in the KRU and KRUN cells, various versions of the so-called "arc protection" have been used. For this protection, sensors are used that react to bright light, high temperature and overpressure accompanying short circuits in the cells.

Photocells installed in the cells of the outgoing lines and in the busbar compartments are used as sensors that react to the bright light of the arc. Photocells are included in the high-speed protection circuits, which trip the corresponding switches with minimal delay.

The sensor, which reacts to the high temperature of the arc, is a cable stretched in the cage, which, when burned, releases the limit switch, the contacts of which act on the tripping circuits of the circuit breaker.

The safety valve is a sensor that reacts to overpressure in the cells. When actuated, it acts on the limit switch, causing the connection switches feeding the section to break.

In addition to the above methods, which prevent the destruction of the cells of complete switchgear from internal short circuits, a high-speed relay protection of the busbars of the 6-10 kV sections is used, which is triggered only in the event of a short circuit of the substation busbars and turns it off with a minimum time delay through switches of the power connections.