The process of forming an electric arc and methods of extinguishing it

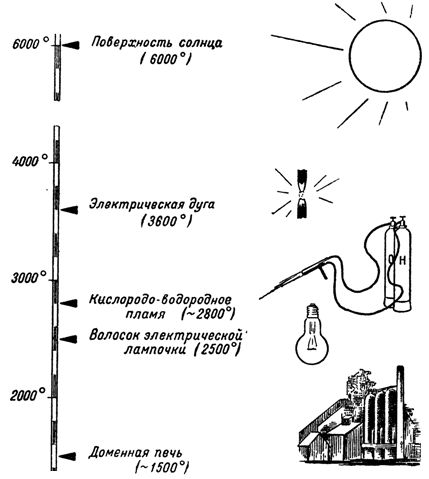

When the electric circuit is opened, an electric discharge occurs in the form of an electric arc. For the appearance of an electric arc, it is enough for the voltage of the contacts to be above 10 V at a current in the circuit of the order of 0.1 A or more. With significant voltages and currents, the temperature inside the arc can reach 3-15 thousand ° C, as a result of which contacts and live parts melt.

At voltages of 110 kV and above, the length of the arc can reach several meters. Therefore, an electric arc, especially in high power circuits, for voltages above 1 kV is a great danger, although serious consequences can also be in installations for voltages below 1 kV. As a result, arcing must be contained as much as possible and quickly extinguished in circuits for voltages both above and below 1 kV.

Causes of electric arcing

The process of forming an electric arc can be simplified as follows.When the contacts diverge, the contact pressure first decreases and the contact surface increases accordingly, transition resistance (current density and temperature — local (in certain areas of the contact area) overheating begins, which further contributes to thermionic radiation, when under the influence of high temperature the speed of electrons increases and they burst from the surface of the electrode.

The process of forming an electric arc can be simplified as follows.When the contacts diverge, the contact pressure first decreases and the contact surface increases accordingly, transition resistance (current density and temperature — local (in certain areas of the contact area) overheating begins, which further contributes to thermionic radiation, when under the influence of high temperature the speed of electrons increases and they burst from the surface of the electrode.

At the moment of contact separation, that is, the circuit is broken, the voltage is quickly restored in the contact gap. Since in this case the distance between the contacts is small, there is electric field high voltage under the influence of which electrons are withdrawn from the surface of the electrode. They accelerate in an electric field and when they hit a neutral atom, they give it their kinetic energy. If this energy is sufficient to tear off at least one electron from the shell of a neutral atom, then the process of ionization takes place.

The formed free electrons and ions make up the plasma of the arc trunk, that is, the ionized channel in which the arc burns and a continuous movement of particles is ensured. In this case, negatively charged particles, mainly electrons, move in one direction (toward the anode), and atoms and molecules of gases deprived of one or more electrons — positively charged particles — in the opposite direction (toward the cathode).

Plasma conductivity is close to that of metals.

Plasma conductivity is close to that of metals.

A large current flows in the arc shaft and a high temperature is created.This temperature of the arc cylinder leads to thermal ionization — the process of ion formation due to the collision of molecules and atoms with high kinetic energy at high speeds of their movement (molecules and atoms of the medium where the arc burns disintegrate into electrons and positively charged ions ). Intense thermal ionization maintains high plasma conductivity. Therefore, the voltage drop along the arc is small.

In an electric arc, two processes are constantly taking place: in addition to ionization, also deionization of atoms and molecules. The latter occurs mainly through diffusion, that is, the transfer of charged particles into the environment and the recombination of electrons and positively charged ions, which reassemble into neutral particles with the return of the energy spent on their disintegration. In this case, the heat is removed to the environment.

Thus, three stages of the considered process can be distinguished: arc ignition, when due to shock ionization and the emission of electrons from the cathode, an arc discharge begins and the intensity of ionization is higher than deionization, stable burning of the arc supported by thermal ionization in the arc cylinder when the intensities of ionization and deionization are the same, disappearance of the arc when the intensity of deionization is higher than that of ionization.

Methods of extinguishing the arc in electrical switching devices

To disconnect the elements of the electrical circuit and exclude damage to the switching device, it is necessary not only to open its contacts, but also to extinguish the arc that appears between them. Arc extinguishing processes, as well as burning, with alternating current and direct current are different.This is determined by the fact that in the first case the current in the arc passes through zero every half-cycle. At these times, the release of energy in the arc stops and the arc spontaneously extinguishes and then re-ignites each time.

In practice, the current in the arc becomes close to zero slightly earlier than the zero crossing, because as the current decreases, the energy supplied to the arc decreases, and the temperature of the arc decreases accordingly and thermal ionization ceases. In this case, the deionization process continues intensively in the arc gap. If you open and quickly open the contacts at this time, then the subsequent electrical interruption may not occur and the circuit will be disconnected without arcing. In practice, however, this is extremely difficult to do, and therefore special measures are taken to accelerate the extinction of the arc, to ensure cooling of the arc space and to reduce the number of charged particles.

As a result of deionization, the dielectric strength of the gap gradually increases and at the same time the recovery voltage in it increases. The ratio of these values depends on whether the rainbow will light up in the next half of the period or not. If the dielectric strength of the gap increases faster and is greater than the recovery voltage, the arc will no longer ignite, otherwise a stable arc will be provided. The first condition defines the arc quenching problem.

Different arc quenching methods are used in switchgear.

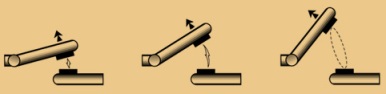

Extending the arc

If the contacts diverge during the disconnection of the electrical circuit, the resulting arc is stretched.At the same time, the cooling conditions of the arc are improved because its surface area increases and more voltage is required for burning.

Splitting a long arc into a series of short arcs

If the arc formed when the contacts open is divided into K short arcs, for example by pulling into a metal grid, it will extinguish. Typically, the arc is introduced into a metal grid under the influence of an electromagnetic field induced in the grid plates by eddy currents. This method of arc quenching is widely used in switchgear for voltages below 1 kV, in particular in automatic air switches.

Arc cooling in narrow slots

Extinguishing small arcs is facilitated. Therefore, in switching devices arc chutes with longitudinal slots are widely used (the axis of such a slot coincides in direction with the axis of the arc cylinder). Such a gap is usually formed in chambers made of insulating arc-resistant materials. Due to the contact of the arc with cold surfaces, its intense cooling occurs, the diffusion of charged particles into the environment and, accordingly, rapid deionization.

In addition to slots with flat-parallel walls, slots with ribs, protrusions, extensions (pockets) are also used. All this leads to deformation of the arc cylinder and increases the area of its contact with the cold walls of the chamber.

The arc is drawn into narrow slots usually by a magnetic field interacting with the arc, which can be thought of as a current-carrying conductor.

External magnetic field to move the arc is most often provided by a coil connected in series with the contacts between which the arc occurs.Narrow slot arc quenching is used in devices for all voltages.

High pressure arc extinguishing

At constant temperature, the degree of gas ionization decreases with increasing pressure, while the thermal conductivity of the gas increases. All other things being equal, this results in improved arc cooling. Arc extinguishing by high pressure, created by the arc itself in tightly closed chambers, is widely used in fuses and a number of other devices.

At constant temperature, the degree of gas ionization decreases with increasing pressure, while the thermal conductivity of the gas increases. All other things being equal, this results in improved arc cooling. Arc extinguishing by high pressure, created by the arc itself in tightly closed chambers, is widely used in fuses and a number of other devices.

Arc quenching in oil

If switching contacts placed in oil, the arc that occurs when they are opened leads to intense evaporation of the oil. As a result, a gas bubble (envelope) is formed around the arc, consisting mainly of hydrogen (70 ... 80%), as well as oil vapor. The emitted gases penetrate directly into the area of the arc cylinder at high speed, cause mixing of cold and hot gas in the bubble, provide intensive cooling and, accordingly, deionization of the arc gap. In addition, the deionizing ability of the gases increases the pressure inside the bubble created during the rapid decomposition of the oil.

The intensity of the arc extinguishing process in the oil is the higher the closer the arc comes into contact with the oil and the faster the oil moves relative to the arc. Given this, the arc gap is limited by a closed insulating device - arc chute... In these chambers, a closer contact of the oil with the arc is created, and with the help of insulating plates and discharge holes, working channels are formed through which the the movement of oil and gases, providing intensive blowout (blowout) of the arc.

Arc chutes according to the principle of operation, they are divided into three main groups: with self-blowing, when high pressure and speed of gas movement are created in the area of the arc due to the energy released in the arc, with forced blowing of oil with the help of special pumping hydraulic mechanisms, with magnetic quenching in oil, when the arc is under the action of the magnetic field, it moves into narrow gaps.

Arc chutes according to the principle of operation, they are divided into three main groups: with self-blowing, when high pressure and speed of gas movement are created in the area of the arc due to the energy released in the arc, with forced blowing of oil with the help of special pumping hydraulic mechanisms, with magnetic quenching in oil, when the arc is under the action of the magnetic field, it moves into narrow gaps.

The most effective and simple self-inflating arc chutes... Depending on the location of the channels and exhaust openings, chambers are distinguished in which intensive blowing of the gas-steam mixture and oil along the current of the arc (longitudinal blowing) or through the arc (transverse blowing) is provided ). The considered arc extinguishing methods are widely used in circuit breakers for voltages above 1 kV.

The most effective and simple self-inflating arc chutes... Depending on the location of the channels and exhaust openings, chambers are distinguished in which intensive blowing of the gas-steam mixture and oil along the current of the arc (longitudinal blowing) or through the arc (transverse blowing) is provided ). The considered arc extinguishing methods are widely used in circuit breakers for voltages above 1 kV.

Other methods of extinguishing the arc in devices for voltages above 1 kV

In addition to the above methods of extinguishing the arc, they also use: compressed air, the flow of which blows the arc along or across, ensuring its intense cooling (instead of air, other gases are used, often obtained from solid gas-generating materials — fibers, vinyl plastic, etc. — at the expense of their decomposition by the burning arc itself), SF6 (sulfur hexafluoride), which has a higher electrical strength than air and hydrogen, as a result of which the arc burning in this gas, even at atmospheric pressure, is quickly extinguished, highly rarefied gas (vacuum) when the contacts are opened, in which the arc does not ignites (extinguishes) after the first passage of the current through zero.

In addition to the above methods of extinguishing the arc, they also use: compressed air, the flow of which blows the arc along or across, ensuring its intense cooling (instead of air, other gases are used, often obtained from solid gas-generating materials — fibers, vinyl plastic, etc. — at the expense of their decomposition by the burning arc itself), SF6 (sulfur hexafluoride), which has a higher electrical strength than air and hydrogen, as a result of which the arc burning in this gas, even at atmospheric pressure, is quickly extinguished, highly rarefied gas (vacuum) when the contacts are opened, in which the arc does not ignites (extinguishes) after the first passage of the current through zero.