Linear fittings of overhead power lines

Linear fittings used to fasten wires in garlands of suspended insulators can be divided into five main types according to their purpose:

1. Clamps used to fasten wires and cables, divided into support, suspended from intermediate supports and tension, used on anchor-type supports.

2. Connecting elements (clamps, earrings, ears, swings) used to connect clamps with insulators, to hang garlands on posts and to connect multi-chain garlands to each other.

3. Protective fittings (rings) installed on strings of 330 kV and higher lines, designed for a more even distribution of voltage between the individual insulators of the column and to protect them from arc damage when overlapping.

4. Connecting fittings used to connect wires and cables in the section, as well as to connect wires in loops of anchor-type supports.

5. Distance elements used to connect separated phase wires to each other.Support brackets consist of a boat in which the wire is laid, dies and bolts (or bolts) to secure the wire in the boat, springs, clamps or clamps to secure the bracket to the garland.

Clamps for fixing wires and cables

According to the strength of the wire attachment, the supporting brackets are divided into the following types:

Blind clamps, where the strength of the termination reaches 30 - 90% of the strength of aluminum wires, 20 - 30% of the strength of steel-aluminum wires and 10 - 15% of the strength of steel cables. With such a termination, in the event of a break in one of the sections, as a rule, the wire and cable are not pulled from the clamp, and the tension of the wire or cable, which remained continuous, is transferred to the intermediate support.

Blind clamps are the main type of clamps currently used on overhead lines.

Blind clamps are the main type of clamps currently used on overhead lines.

Falling clamps (also called release), throwing out a boat with wire when the carrier string is deflected at a certain angle, (about 40 °) in the event of a wire break in one of the sections. Thus, the wire tension, which remains continuous, is not transferred to the intermediate support. This feature of the drop clamp allows the mass of the intermediate support to be reduced somewhat. However, in operation, there were cases of wires being thrown from falling clamps during dances and uneven ice loading in adjacent sections. Therefore, falling parentheses are not currently used and are not discussed below.

Multi-functional hangers are essentially not clamps, since the wire can roll freely on the rollers with a difference in tension in adjacent sections.Multi-functional hangers are used for fastening wires with a cross-section equal to or greater than 300 mm2 and cables on intermediate supports with large transitions. At the same time, the protection of the steel-aluminum wires is provided by special flexible connectors, which are installed on the wires in the areas of their possible movement on the rollers.

Blind clamps for phase divided into three conductors consist of a body, dies, tension bolts with nuts and aluminum gaskets. The previously produced spaced bolt and die bolt clamps have now been replaced with hinge side bolt clamps. With the new clamps, limited wire movement is possible from side to side of the span, reducing wire damage from vibration .

Tension clamps are used for the installation of steel-aluminum wires with a cross-section of 300 mm2 and more. They consist of a steel armature in which the steel core of the wire is crimped and an aluminum jacket in which the aluminum portion of the wire is crimped to the side of the section.

The disadvantage of compression tension anchor clamps is the need to cut the wire to crimp it. Therefore, a press clamp for tensioning steel-aluminum wires of the «prez» type is produced, in which the wire can be installed without cutting. However, clamps of this type are significantly heavier than conventional compression clamps.

For monometallic wires and steel cables, clamping clamps with a simpler design are produced, consisting of a bushing for pressing the wire and a part for hanging the bushing on the garland.

Clamps for tensioning wedges are used for hanging steel ropes.They consist of a body and a double gusset. When the cable is pulled, the wedge presses the cable against the body, which ensures reliable termination.

Connecting fittings of overhead power lines

The connecting elements are divided into clamps that serve to fasten the garland to the support or to the parts fixed to the support, earrings connected on the one hand with clamps or to parts of the support, and on the other hand with insulating caps, ears that serve to connecting the insulating bars with clamps or other details of the garland on the side of the wire.

The connecting elements are divided into clamps that serve to fasten the garland to the support or to the parts fixed to the support, earrings connected on the one hand with clamps or to parts of the support, and on the other hand with insulating caps, ears that serve to connecting the insulating bars with clamps or other details of the garland on the side of the wire.

Connecting elements also include intermediate links used to extend garlands and swings that serve to move from one to two or more suspension points.

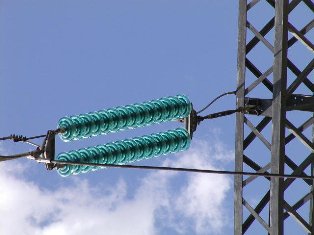

Protective fittings for overhead power lines

Protective fittings can be made in the form of horns or rings. Protective rings for supporting strings of lines with a voltage of 330 kV and more are made in the form of ovals, mounted with the longer side along the line.

Currently, on 330 and 500 kV lines, special supporting clamps are used with the arrangement of conductors approximately at the level of the skirt of the lower insulator.

In the case of insulated suspension of the cable on lines with a voltage of 220 kV and more, the insulators are shunted by exhaust horns.

The suspension of load-bearing garlands on intermediate supports is carried out using KGP-type attachment points, consisting of a U-shaped bolt with nuts fixed in the holes of the traverse. The attachment kit includes a clip or earring to hang the garland. The tension garlands are fixed on the supports using KG or KGN attachment points. Sketches of attachment points are given in the linear reinforcement catalogues.

Connecting fittings of overhead power lines

Connectors designed for connecting wires and cables are divided into oval and extruded.

Oval connectors are used for wires with a cross-section up to and including 185 mm2. In them, the wires are overlapped, after which the connector is pressed using special pliers. The steel-aluminum conductors with a section up to and including 95 mm2 are fixed in the connectors by twisting.

Bending connectors are used to connect wires with a cross-section of more than 185 mm2 and for steel cables of all cross-sections. The extruded connector for steel-aluminum conductors consists of a formed steel tube extruded on the steel core and an aluminum tube extruded on the aluminum part of the conductor. Connectors for monometallic conductors and steel cables consist of a single tube.

Remote elements

Distributors mounted on the phase-split conductors to ensure the required distance c between the conductors consist of two pairs of matrices fixed to the conductors with bolts and a rigid rod hinged to the matrices. At present, only distance spacers are used.

Experience with the operation of the release struts proved unsatisfactory, as struts of this type were thrown out when the wires danced; therefore their use is not permitted. In the hinges of the anchor supports, weighted supports with weights are installed, which limit the swinging of the hinges.