Synchronous compensators in electrical networks

The synchronous compensator is a lightweight synchronous motor designed for idle operation.

The synchronous compensator is a lightweight synchronous motor designed for idle operation.

The main consumers of electrical energy, in addition to active power, consume from the generators of the system reactive power… The number of users requiring large magnetizing reactive currents to create and maintain magnetic flux include asynchronous motors, transformers, induction furnaces, and others. As a result, distribution networks are usually operated with lagging current.

The reactive power generated by the generator is obtained at the lowest cost. However, the transfer of reactive power from generators is associated with additional losses in transformers and transmission lines. Therefore, to obtain reactive power, it becomes economically advantageous to use synchronous compensators located at the nodal substations of the system or directly at the consumers.

Synchronous motors, thanks to DC excitation, they can work with cos = 1 and do not consume reactive power from the network, and during operation, with overexcitation, they give reactive power to the network. As a result, the power factor of the network is improved and the voltage drop and losses in it are reduced, as well as the power factor of the generators operating in power plants.

Synchronous compensators are designed to compensate the power factor of the network and maintain the normal voltage level of the network in areas where consumer loads are concentrated.

A synchronous compensator is a synchronous machine operating in motor mode without shaft load with alternating current in the field.

In the overexcitation mode, the current leads the mains voltage, that is, it is capacitive with respect to this voltage, and in the underexcitation mode, it lags behind, inductive. In this mode, the synchronous machine becomes a compensator — a reactive current generator.

The overexcited mode of operation of the synchronous compensator is normal when it supplies reactive power to the grid.

Synchronous compensators are devoid of drive motors and in terms of their operation are essentially synchronous idler motors.

For this purpose, each synchronous compensator is equipped with an automatic excitation or voltage regulator, which regulates the magnitude of the excitation current so that the voltage at the terminals of the compensator remains constant.

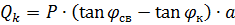

In order to improve the power factor and accordingly reduce the offset angle between the current and the voltage from the value of φw to φc, reactive power is required:

where P is the average active power, kvar; φsv — phase shift corresponding to the weighted average power factor; φk — phase shift to be obtained after compensation; a — a factor equal to about 0.9 entered into the calculations to take into account a possible increase in the power factor without installing compensating devices.

In addition to reactive current compensation inductive industrial loads, synchronous line compensators are required. In long transmission lines, at low load, line capacity prevails and they operate with leading current. To compensate for this current, the synchronous compensator must operate with lagging current, i.e., with insufficient excitation.

With a significant load on power lines, when the inductance of electricity consumers prevails, the power line operates with a lagging current. In this case, the synchronous compensator must operate with leading current, i.e. overexcited.

A change in the load on the power line causes a change in the reactive power flows in magnitude and phase and leads to significant fluctuations in the line voltage. In this regard, it becomes necessary to regulate.

Synchronous compensators are usually installed at regional substations.

To regulate the voltage at the end or in the middle of the transit power lines, intermediate substations can be created with synchronous compensators, which must regulate or keep the voltage unchanged.

The operation of such synchronous compensators is automated, which creates the possibility of smooth automatic control of the generated reactive power and voltage.

To perform asynchronous starting, all synchronous compensators are provided with starting coils in pole parts or their poles are massive. In this case, the direct method and, if necessary, the reactor start-up method are used.

In some cases, powerful compensators are also put into operation using start-phase induction motors mounted with them on the same shaft. For synchronization with the network, the self-synchronization method is usually used.

Since synchronous compensators do not develop active power, the question of the static stability of work for them loses its urgency. Because of this, they are manufactured with a smaller air gap than generators and motors. Reducing the gap makes field winding easier and lowers machine costs.

Rated apparent power of the synchronous compensator corresponds to its operation with overexcitation, i.e. the rated power of the synchronous compensator is its reactive power at leading current, which it can carry for a long time in operating mode.

The highest underexcitation current and power values are obtained when operating in reactive mode.

In most cases, the underexcitation mode requires less power than the overexcitation mode, but in some cases more power is required. This can be achieved by increasing the gap, but this leads to an increase in the cost of the machine, and therefore the question of using a negative excitation current mode has recently been raised. Since the synchronous compensator in terms of active power is only loaded with losses, it can, according to him, work stably and with little negative excitation.

In some cases, in dry periods, for operation in compensator mode, they are also used hydroelectric generators.

Structurally, compensators do not fundamentally differ from synchronous generators. They have the same magnet system, excitation system, cooling etc. All medium power synchronous compensators are air cooled and made with exciter and exciter.

Due to the fact that synchronous compensators are not designed to perform mechanical work and do not carry an active load on the shaft, they have a mechanically light construction. Compensators are produced as relatively low-speed machines (1000 - 600 rpm) with a horizontal shaft and a convex pole rotor.

An idle generator with suitable excitation can be used as a synchronous compensator.In an overexcited generator an equalizing current appears which is purely inductive with respect to the generator voltage and purely capacitive with respect to the grid.

It must be borne in mind that an over-excited synchronous machine, whether operating as a generator or as a motor, may be regarded relative to the mains as a capacitance, and an unexcited synchronous machine as an inductance.

To transfer the grid-connected generator to the synchronous compensator mode, it is enough to close the access of steam (or water) to the turbine. In this mode, the overexcited turbine-generator begins to consume a small amount of active power from the grid only to cover the rotation losses (mechanical and electrical) and transfers the reactive power to the grid.

In the mode of synchronous compensator, the generator can work for a long time and depends only on the operating conditions of the turbine.

If necessary, the turbine generator can be used as a synchronous compensator both with the turbine rotating (together with the turbine) and with it turned off, i.e. with the clutch disassembled.

Spinning the steam turbine on the side of the generator that has gone into drive mode can cause the tail section of the turbine to overheat.