Classification of automatic control systems

The set of automatic control device and control object connected and interacting with each other in accordance with the control algorithm is called automatic control system (ACS).

Automatic control systems can be classified according to the control method and functional characteristics. According to the control method, all systems are divided into two large classes: ordinary (non-self-regulating) and self-regulating (adaptive).

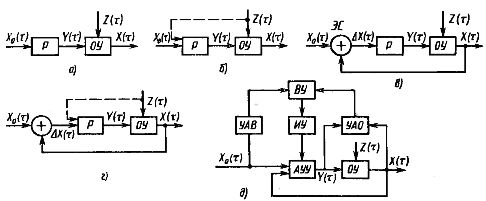

Ordinary systems belonging to the simple category do not change their structure in the course of management. They are the most developed and widely used in foundries and thermal workshops. Common automatic control systems are divided into three subclasses: open, closed, and combined control systems.

Open-loop automatic control systems, in turn, are divided into automatic rigid control systems (SZHU) and disturbance control systems.

In the first systems, the regulator acts on the control object regardless of the obtained result, that is, the value of the controlled variable and the external disturbance. Disturbance control systems work on the principle that the control action is generated depending on the external disturbances that affect the control object.

As an example, consider the heating system of a foundry or thermal workshop. In this case, the consumption of hot water in the store's heating pipe depends on the external weather conditions. The colder it is outside, the more hot water is supplied to the radiators and vice versa.

Closed automatic control systems operating on the deflection principle are also called automatic control systems (ACS). Their distinguishing feature is the presence of a closed cycle of signal passage, i.e. the presence of a return channel through which information about the state of the controlled variable is transmitted to the input of the comparison element.

Automatic control systems are designed to solve three problems: stabilization of the controlled value (stabilizing ATS), changing the controlled value according to known (programmed ATS) or unknown (tracking ATS) programs.

In ATS stabilization, the setpoint of the controlled variable is constant. An example of such a system is the temperature control system in the working space of a thermal furnace. In software ATS, the value of the controlled variable changes over time according to a pre-designed (known) program.

In servo systems, the set value of the controlled variable changes over time according to a previously unknown program.Tracking and software ATSs differ from stabilizers in the principle of processing the reference signal.

The most typical example of servo control is the automatic maintenance of a given ratio between the consumption of fuel and air when regulating the combustion process in furnaces for melting and heating fuel.

Automatic control systems: a — open, b — bias open, c — closed, d — combined, d — self-regulating, P — controller, OU — control object, ES — comparison element, UAV — device for analysis of the control action: VU — computing device, IU is executive device, AUU is automatic control device, AUO is control object analysis device.

Combined systems combine the advantages of deviation and disturbance control systems, which increases control accuracy. The effect of unaccounted disturbances in combined systems is compensated or attenuated by bias control.

Self-regulating (adaptive) systems can be divided into three subclasses: extreme systems, self-tuning systems, and self-tuning systems.

Extreme regulation systems are called stabilizing, tracking, or programmed control systems in which the setting, program, or reproduction law automatically changes depending on changes in external conditions or the internal state of the system to create the most favorable ( optimal) mode of operation of a control object.

In such systems, instead of a permanent setting or program, an automatic search device is installed, which analyzes each characteristic of the object (efficiency, productivity, economy, etc.) and, depending on the obtained result, supplies the required value of a controlled variable to the control device, so that this characteristic has an outstanding value with a continuous change in various disturbing influences that affect the operating conditions of the system.

In systems with self-tuning parameters, when the external conditions or characteristics of the controlled object change, there is an automatic (not according to a predetermined program) change in the variable parameters of the control device to ensure stable operation of the system and maintain the controlled value at a given or optimal level.

In systems with a self-adjusting structure, when the external conditions and characteristics of the control object change, the elements in the connection scheme are switched or new elements are introduced into it. The purpose of these changes (choice) of the structure is to achieve a better solution to the management problem.

The selection of the structure is done by automatic search using computational and logical operations. Such systems must not only adapt to all changes in external conditions and characteristics of the object, but also function normally even in the presence of malfunctions or damage to individual elements, creating new circuits to replace the broken ones. Self-regulating systems can be made to improve, "gain experience" by quickly trying several options, choosing and "remembering" the best one.

Functional classification all automatic control systems are divided into four classes:

-

systems for coordinating the work of mechanisms,

-

systems for regulating the parameters of technological processes,

-

automatic control systems,

-

automatic protection and blocking systems.

Systems designed to coordinate the operation of individual mechanisms of the plant or the plant as a whole automatic rigid control systems (SZHU).

Automatic control systems (ACS) technological processes ensure the maintenance of the controlled value at a given level or its change according to a given program.

Automatic control systems (ACS) contain means and methods for obtaining information about the current values of technological process parameters (temperature, pressure, dustiness or gas content in the air, etc.) without direct human involvement.

Automatic protection systems (SAZ) and blocking systems (SAB) prevent the occurrence of emergency situations when operating equipment in a stable state.