Induction heating, hardening and induction melting of metals

The most perfect type of heating is the one in which the heat is generated directly in the heated body. This method of heating is very well done by passing an electric current through the body. However, direct - the inclusion of a heated body in an electrical circuit is not always possible for technical and practical reasons.

In these cases, a perfect type of heating can be realized using induction heating, where the heat is also generated in the heated body itself, which eliminates unnecessary, usually large, energy consumption in the walls of the furnace or in other heating elements. Therefore, despite the relatively low efficiency of generating currents of increased and high frequency, the overall efficiency of induction heating is often higher than with other heating methods.

The induction method also allows rapid heating of non-metallic bodies evenly throughout their thickness.The poor thermal conductivity of such bodies excludes the possibility of rapid heating of their inner layers in the usual way, that is, by supplying heat from the outside. In the induction method, heat is generated in the same way both in the outer layers and in the inner ones, and there may even be a risk of overheating of the latter if the necessary thermal insulation of the outer layers is not done.

A particularly valuable property of induction heating is the possibility of a very high concentration of energy in the heated body, easily amenable to accurate dosing. Only electric arc the same order of energy density can be obtained, but this heating method is difficult to control.

The characteristics and well-known advantages of induction heating have created wide opportunities for its application in many industries. In addition, it allows you to create new types of structures that are not at all feasible for conventional heat treatment methods.

A physical process

In induction furnaces and devices, heat in an electrically conductive heated body is released by currents induced in it by an alternating electromagnetic field. In this way, direct heating takes place here.

Induction heating of metals is based on two physical laws: the Faraday-Maxwell law of electromagnetic induction and the Joule-Lenz law. Metal bodies (blanks, parts, etc.) are placed alternating magnetic field, which stirs up a whirlwind in them electric field… The EMF of the induction is determined by the rate of change of the magnetic flux. Under the action of induction EMF, eddy currents (closed inside the bodies) flow in the bodies, releasing heat according to the Joule-Lenz law… This EMF is created in the metal alternating current, the thermal energy released by these currents causes metal to heat up. Induction heating is direct and non-contact. It allows you to reach a temperature sufficient to melt the most refractory metals and alloys.

Intense induction heating is possible only in electromagnetic fields of high intensity and frequency, which are created by special devices - inductors. Inductors are powered by a 50 Hz network (industrial frequency installations) or by separate energy sources — medium and high frequency generators and converters.

The simplest inductor of low-frequency indirect induction heating devices is an insulated wire (extended or coiled) placed inside a metal tube or superimposed on its surface. As current flows through the inductor wire in the tube, it heats up eddy currents… Heat from the tube (can also be a crucible, container) is transferred to the heated medium (water flowing through the tube, air, etc.).

Induction heating and hardening of metals

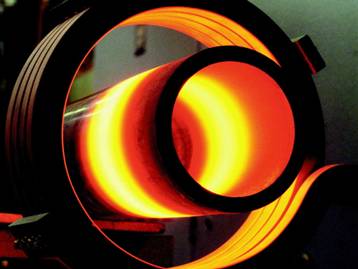

The most widely used direct induction heating of metals at medium and high frequencies. For this, inductors with a special design are used. The inductor emits electromagnetic wave, which falls on the heated body and dies in it. The energy of the absorbed wave is converted into heat in the body. The heating coefficient is the higher the closer the shape of the emitted electromagnetic wave (flat, cylindrical, etc.) to the shape of the body. Therefore, flat inductors are used for heating flat bodies, cylindrical (solenoid) inductors are used for cylindrical workpieces.In the general case, they can have a complex shape due to the need to concentrate the electromagnetic energy in the desired direction.

A characteristic of the induction energy input is the ability to regulate the spatial arrangement of the flow zone eddy currents.

First, eddy currents flow in the area covered by the inductor. Only that part of the body that is in magnetic contact with the inductor is heated, regardless of the overall size of the body.

Second, the depth of the eddy current circulation zone and therefore the energy release zone depends, among other factors, on the frequency of the inductor current (increases at low frequencies and decreases with increasing frequency).

The efficiency of energy transfer from the inductor to the heated current depends on the size of the gap between them and increases as it decreases.

Induction heating is used for surface hardening of steel products, by heating for plastic deformation (forging, stamping, pressing, etc.), metal melting, heat treatment (annealing, tempering, normalizing, hardening), welding, layering, metal brazing.

Indirect induction heating is used for heating process equipment (pipelines, containers, etc.), heating liquid media, drying coatings, materials (for example, wood). The most important parameter of induction heating installations is the frequency. For each process (surface hardening, by heating) there is an optimal frequency range that provides the best technological and economic indicators. Frequencies from 50 Hz to 5 MHz are used for induction heating.

Advantages of induction heating

1) Transferring electrical energy directly into the heated body allows direct heating of conductive materials. In this case, the heating rate is increased compared to installations with indirect action, where the product is heated only from the surface.

2) The transfer of electrical energy directly into the heated body does not require contact devices. It is convenient in the conditions of automated manufacturing production, when vacuum and protective means are used.

3) Due to the phenomenon of surface effect, the maximum power is released in the surface layer of the heated product. Therefore, induction heating during cooling provides rapid heating of the surface layer of the product. This makes it possible to obtain a high surface hardness of the part with a relatively viscous medium. Induction surface hardening is faster and more economical than other surface hardening methods.

4) Induction heating in most cases improves productivity and improves working conditions.

Induction melting furnace

An induction furnace or device can be thought of as a type of transformer in which the primary coil (inductor) is connected to an alternating current source and the heated body itself serves as the secondary coil.

The working process of induction melting furnaces is characterized by electrodynamic and thermal movement of liquid metal in a bath or crucible, which contributes to obtaining metal with the same composition and its uniform temperature throughout the volume, as well as low metal waste (several times less slightly than in arc furnaces).

Induction melting furnaces are used in the production of castings, including shaped, from steel, cast iron, non-ferrous metals and alloys.

Induction melting furnaces can be divided into industrial frequency channel furnaces and industrial, medium and high frequency crucible furnaces.

An induction duct furnace is a transformer, usually at power frequency (50 Hz). The secondary winding of the transformer is a molten metal winding. The metal is enclosed in an annular refractory channel.

The main magnetic flux induces an EMF in the metal of the channel, the EMF creates a current, the current heats the metal, therefore an induction channel furnace is similar to a transformer operating in short-circuit mode.

Inductors of channel furnaces are made of longitudinal copper tube, it is water-cooled, the channel part of the hearth is cooled by a fan or by a centralized air system.

Channel induction furnaces are designed for continuous operation with rare transitions from one class of metal to another. Channel induction furnaces are mainly used for melting aluminum and its alloys, as well as copper and some of its alloys. Other series of furnaces are specialized as mixers for holding and superheating liquid iron, non-ferrous metals and alloys prior to casting in foundry molds.

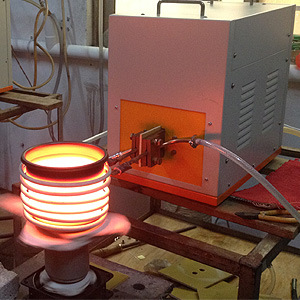

The operation of an induction crucible furnace is based on the absorption of electromagnetic energy by a conductive charge. The cell is placed inside a cylindrical coil - an inductor. From an electrical point of view, an induction crucible furnace is a short-circuited air transformer whose secondary winding is a conducting charge.

Induction crucible furnaces are mainly used for melting die casting metals in a batch mode of operation and, regardless of the mode of operation, for melting certain alloys, such as bronzes, which adversely affect the lining of channel furnaces.