Elements of automatic systems

Any automatic system consists of separate structural elements, interconnected and performing certain functions, which are usually called elements or means of automation... From the point of view of the functional tasks performed by the elements in the system, they can be divided into perceiving, setting , comparing, transforming, executive and corrective.

Any automatic system consists of separate structural elements, interconnected and performing certain functions, which are usually called elements or means of automation... From the point of view of the functional tasks performed by the elements in the system, they can be divided into perceiving, setting , comparing, transforming, executive and corrective.

Sensor elements or primary transducers (sensors) measure the controlled quantities of technological processes and convert them from one physical form to another (for example, thermoelectric thermometer converts the temperature difference into thermoEMF).

Setting elements of the automation (setting elements) serve to set the required value of the controlled variable Xo. Its actual value must match this value. Examples of actuators: mechanical actuators, electrical actuators such as variable resistance resistors, variable inductors and switches.

Comparators for automation compare the preset value of the controlled value X0 with the actual value X. The error signal received at the output of the comparator ΔX = Xo — X is transmitted either through the amplifier or directly to the drive.

Transforming elements perform the necessary signal conversion and amplification in magnetic, electronic, semiconductor and other amplifiers when the signal power is insufficient for further use.

Executive elements create control actions on the control object. They change the amount of energy or matter supplied to or removed from the controlled object so that the controlled value corresponds to a given value.

Corrective elements serve to improve the quality of the management process.

In addition to the main elements in automatic systems, there are also subsidiaries, which include switching devices and protective elements, resistors, capacitors and signaling equipment.

Everything automation elements regardless of their purpose, they have a certain set of characteristics and parameters that determine their operational and technological characteristics.

The main of the main characteristics is a static characteristic of an element... It represents the dependence of the output value Хвх on the input Хвх in stationary mode, i.e. Xout = f(Xin). Depending on the influence of the sign of the input quantity, irreversible (when the sign of the output quantity remains constant throughout the range of variation) and reversible static characteristics (when a change in the sign of the input quantity leads to a change in the sign of the output quantity) are distinguished.

A dynamic characteristic is used to evaluate the performance of an element in a dynamic mode, i.e. with rapid changes in the input value. It is set by the transient response, transfer function, frequency response. The transient response is the dependence of the output value Xout on the time τ: Xvx = f (τ) — with a jump-like change of the input signal Xvx.

A transmission factor can be determined from the static characteristics of the element. There are three types of transmission factors: static, dynamic (differential), and relative.

Static gain Kst is the ratio of the output value Xout to the input Xin, that is, Kst = Xout / Xvx. The transfer factor is sometimes called the conversion factor. In relation to specific structural elements, the static transmission ratio is also called gain (in amplifiers), reduction ratio (in gearboxes), transformation factor (in transformers) etc.

For elements with a non-linear characteristic, a dynamic (differential) transfer coefficient Kd is used, i.e. Kd = ΔХвх /ΔXvx.

Relative transmission coefficient Cat is equal to the ratio of the relative change in the output value of the element ΔXout / Xout.n to the relative change of the input quantity ΔXx / Xx.n,

Cat = (ΔXout / Xout.n) /ΔXvx / Xvx.n,

where Xvih.n and Xvx.n — nominal values of output and input quantities. This coefficient is a dimensionless value and is convenient when comparing elements that are different in design and principle of operation.

Sensitivity threshold — the smallest value of the input quantity at which there is a noticeable change in the output quantity.It is caused by the presence of friction elements in structures without lubricants, gaps and backlash in the joints.

A characteristic feature of automatic closed systems, where the principle of control by deviation is used, is the presence of feedback. Let's look at the principle of feedback using the example of a temperature control system for an electric heating furnace. In order to maintain the temperature within the specified limits, the control action entering the facility, ie. the voltage supplied to the heating elements is formed taking into account the temperature value.

Using a primary temperature transducer, the output of the system is connected to its input. Such a link, that is, a channel through which information is transmitted in the opposite direction compared to the control action, is called a feedback link.

Feedback it can be positive and negative, rigid and flexible, basic and additional.

A positive feedback relationship is invoked when the signs of feedback and referent influence match. Otherwise, the feedback is called negative.

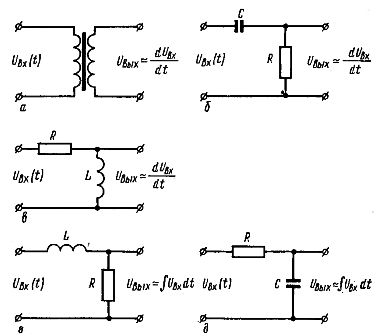

Flexible feedback circuits: a, b, c — differentiation, d and e — integration

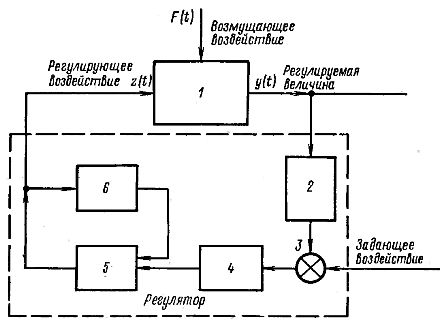

Scheme of the simplest automatic control system: 1 — control object, 2 — main feedback link, 3 — comparison element, 4 — amplifier, 5 — actuator, 6 — feedback element, 7 — correction element .

Scheme of the simplest automatic control system: 1 — control object, 2 — main feedback link, 3 — comparison element, 4 — amplifier, 5 — actuator, 6 — feedback element, 7 — correction element .

If the transmitted action depends only on the value of the controlled parameter, i.e. it does not depend on time, then such a connection is considered rigid. Hard feedback operates in both steady and transient states.A flexible loopback refers to a link that operates only in transient mode. Flexible feedback is characterized by the transmission along it to the input of the first or second derivative of the change in the controlled variable over time. In flexible feedback, the output signal exists only when the controlled variable changes over time.

Basic feedback connects the output of the control system to its input, i.e. it connects the controlled value to the main one. The rest of the reviews are considered supplementary or local. Additional feedback transmits an action signal from the output of each link in the system to the input of each previous link. They are used to improve the properties and characteristics of individual elements.