Materials used to make electrical contacts

The service life and reliability of the contact largely depend on the material of the contact.

Contact material requirements:

1. High electrical conductivity and thermal conductivity.

2. Corrosion resistant.

3. Resistance to high r film formation.

4. Low hardness of the material, to reduce the pressing force.

5. High hardness to reduce mechanical wear during frequent switching on and off.

6. Low erosion.

7. High arc resistance (melting point).

8. High current and voltage required for arcing.

9. Easy handling and low cost.

The listed requirements are contradictory and it is almost impossible to find a material that meets all these requirements.

The following materials are used for contact connections:

Med. Meets almost all of the above requirements, except for corrosion resistance. Copper oxides have low conductivity. Copper is the most common contact material and is used for both detachable and switching contacts.In detachable joints, anti-corrosion coatings are used on the working surfaces.

Med. Meets almost all of the above requirements, except for corrosion resistance. Copper oxides have low conductivity. Copper is the most common contact material and is used for both detachable and switching contacts.In detachable joints, anti-corrosion coatings are used on the working surfaces.

In switching contacts, copper is used when pressing above 3 N for all modes of operation except long-term. For continuous operation, copper is not recommended, but if used, measures should be taken to combat oxidation of the working surfaces. Copper can also be used for arc contacts. At low contact pressure (P < 3 N) the use of copper contacts is not recommended.

Silver. Very good contact material that meets all requirements except arc resistance at high currents. It has good wear resistance at low currents. Silver oxides have almost the same conductivity as pure silver. Silver is used for main contacts in high current devices, for all contacts with continuous operation. In contacts for low currents at low pressure (relay contacts, auxiliary circuit contacts).

Silver is usually used in the form of overlays — the entire part is made of copper or other material on which a silver coating is welded (soldered) to form a working surface.

Aluminum. Compared to copper, it has significantly lower conductivity and mechanical strength. It forms a poorly conductive solid oxide film, which greatly limits its use. Can be used in collapsible contact connections (busbars, field wires). For this purpose, the contact working surfaces are silver, copper-plated or copper-reinforced.

However, the low mechanical strength of aluminum should be taken into account, as a result of which the joints may weaken over time and the contact may break (the contact pressure should not be overestimated).Aluminum is not suitable for switching contacts.

Platinum, gold, molybdenum. They are used for switching contacts for very low currents at low pressure. Platinum and gold do not form oxide films. Contacts made of these metals have low transient resistance.

Tungsten and tungsten alloys. With high hardness and high melting point, they have high electrical wear resistance. Tungsten and tungsten-molybdenum alloys, tungsten-platinum and others are used at low currents for contacts with a high breaking frequency. At medium and high currents, they are used as arc contacts to interrupt currents up to 100 kA and more.

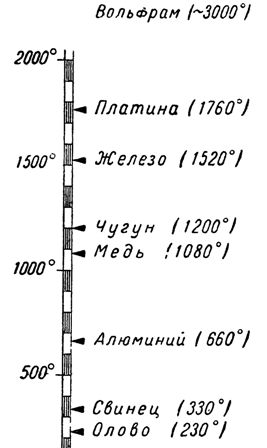

Melting points of various conducting materials

Sintered metal — a mechanical mixture of two practically unalloyed metals obtained by sintering a mixture of their powders or impregnating one with a melt of the other. In this case, one of the metals has good conductivity, while the other has high mechanical strength, is refractory and arc resistant. In this way, metal ceramics combine high arc resistance with relatively good conductivity.

The most common metal-ceramic compositions are: silver - tungsten, silver - molybdenum, silver - nickel, silver cadmium oxide, silver - graphite, silver - graphite - nickel, copper - tungsten, copper - molybdenum, etc. Silver, mainly for alternating current) for medium and large intermittent currents, as well as for main contacts for rated currents up to 600 A.