Executive DC motors and tachogenerators

DC executive motors

Direct current actuators are low-power machines used in automation and telemechanics, in automatic control, regulation and control systems of automated installations, where they convert the electrical signal of a measuring device — a control voltage — into an angular movement of a shaft to affect of control, regulating or control apparatus... In cases where the input signal is insufficient to drive the drive motor, a magnetic or semiconductor power amplifier is used.

Direct current actuators are low-power machines used in automation and telemechanics, in automatic control, regulation and control systems of automated installations, where they convert the electrical signal of a measuring device — a control voltage — into an angular movement of a shaft to affect of control, regulating or control apparatus... In cases where the input signal is insufficient to drive the drive motor, a magnetic or semiconductor power amplifier is used.

Drive motors typically operate with frequent starts, stops, and reverses. They feature significant starting torque and speed. In most cases, the dependences of the armature torque and speed on the control voltage are close to linear.

Depending on the power supply system of the electrical circuits, a distinction is made between armature-controlled and pole-controlled drive motors.In armature control, the control winding is the armature winding in connection with which the control voltage is supplied to its terminals, and the constant excitation current provides an independent source of constant voltage electrical energy. In the case of pole control, the control coil serves as the primary pole excitation coil and the control voltage is supplied to its terminals, and the armature terminal voltage set by an independent DC voltage source remains unchanged.

Depending on the power supply system of the electrical circuits, a distinction is made between armature-controlled and pole-controlled drive motors.In armature control, the control winding is the armature winding in connection with which the control voltage is supplied to its terminals, and the constant excitation current provides an independent source of constant voltage electrical energy. In the case of pole control, the control coil serves as the primary pole excitation coil and the control voltage is supplied to its terminals, and the armature terminal voltage set by an independent DC voltage source remains unchanged.

Anchor steering is usually used. Reversing the polarity of the control voltage causes the armature to rotate in the opposite direction.

Executive DC motors are manufactured with power ratings from a fraction of a watt to 600 W of normal and special designs.

Motors of normal design are similar to DC machines for general use, but differ from them in that the frame with the main poles, like the armature, is assembled from thin sheets of electrical steel insulated from each other, which improves the properties of these machines in transient conditions. In addition, there are no additional poles in these machines, since the armature reaction is small and the switching processes are completely satisfactory. Since the armature speed is low, there is no fan on the shaft of such motors.

Motors of normal design are similar to DC machines for general use, but differ from them in that the frame with the main poles, like the armature, is assembled from thin sheets of electrical steel insulated from each other, which improves the properties of these machines in transient conditions. In addition, there are no additional poles in these machines, since the armature reaction is small and the switching processes are completely satisfactory. Since the armature speed is low, there is no fan on the shaft of such motors.

Motors of special design include magnetoelectric machines with excitation of the main magnetic field using permanent magnets, as well as low-inertia machines that differ in the design of the armature.The latter include: motors with a hollow non-magnetic armature - a hollow thin-walled plastic cylinder with a pressed coil of copper wire with an internal fixed ferromagnetic magnetic circuit mounted on a bearing shield, and less durable motors with a disc armature - a thin non-magnetic disc made of ceramics, textolite , glass, and sometimes aluminum with a printed coil, which is a set of copper foil wires, radially located on both sides of the disk, on which silver-graphite brushes slide. The mentioned designs are characterized by a low moment of inertia of the armature, which provides high speed of the executive motor.

The mass of direct current executive motors is 2 — 4 times smaller than the mass of asynchronous executive motors with the same rated power, and their efficiency at rated power 5 ... 10 W is about 0.3 and reaches a value of 0.65 and a little higher for motors with a nominal power of 200 — 300 W.

DC tachogenerators

DC tachogenerators are low-power machines designed to convert a mechanical value into an electrical signal—an output voltage. In particular, they are used to control and measure the speed of the drive shaft to which the tachogenerator shaft is connected, the armature clamps of which are connected to the measuring device. In addition, tachogenerators are used in electromechanical computing devices to perform computational operations, as well as in devices for automatic processing of generated accelerating and damping signals.

DC tachogenerators are low-power machines designed to convert a mechanical value into an electrical signal—an output voltage. In particular, they are used to control and measure the speed of the drive shaft to which the tachogenerator shaft is connected, the armature clamps of which are connected to the measuring device. In addition, tachogenerators are used in electromechanical computing devices to perform computational operations, as well as in devices for automatic processing of generated accelerating and damping signals.

Tacho generators are magnetoelectric with excitation of the main magnetic field by means of permanent magnets and electrodynamic with electromagnetic excitation due to the magnetic field. excitation coil fed by an independent DC voltage source.

The output voltage of the tachogenerator in idle mode varies linearly with the speed of the armature, and under load this linearity is somewhat disturbed, and the more, the less resistance the measuring device connected to the armature clamps has. Nevertheless, for any tachogenerator there is a relatively small range of measured speeds within which, given a sufficiently large measuring device resistance and constant excitation circuit conditions, the output characteristic can be considered practically linear.

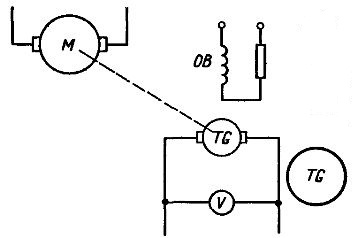

Schematic of inclusion of a direct current tachogenerator of independent excitation

A significant disadvantage of DC tachogenerators is the fluctuation of the output voltage due to a slight periodic change in the magnetic flux due to the uneven air gap and the unequal conductivity of the armature in different radial directions, including those caused by the tooth structure of its magnetic circuit, as well as due to the vibrations of the brushes, roughness and ellipticity of the collector and switching processes — largely eliminated in a hollow-armature tachogenerator, which is designed in the same way as a low-inertia DC executive motor with a similar armature.

A significant disadvantage of DC tachogenerators is the fluctuation of the output voltage due to a slight periodic change in the magnetic flux due to the uneven air gap and the unequal conductivity of the armature in different radial directions, including those caused by the tooth structure of its magnetic circuit, as well as due to the vibrations of the brushes, roughness and ellipticity of the collector and switching processes — largely eliminated in a hollow-armature tachogenerator, which is designed in the same way as a low-inertia DC executive motor with a similar armature.

The inaccuracy of the installation of the brushes on the geometric neutrality of the collector of the tachometer leads to asymmetry of the output voltage, i.e.to generate two different voltages in the armature winding in opposite directions of its rotation at the same speed. With the correct arrangement of the brushes, the voltage asymmetry is in the range of 0.3 to 1% of the rated voltage of the tachogenerator.