Resistors for starting and controlling rheostats

Depending on the purpose, resistors are divided into the following groups:

- starting resistors to limit the current at the moment of connecting a stationary motor to the network and to maintain the current at a certain level during its acceleration;

- braking resistors to limit the motor current when braking;

- regulating resistors for regulating current or voltage in an electrical circuit;

- additional resistors connected in series in the circuit electrical appliances in order to reduce the stress on it;

- discharge resistorsconnected in parallel with the windings of electromagnets or other inductances to limit tripping surges or delay the release of relays and contactors, such resistors are also used to discharge capacitive storage devices;

- ballast resistors connected in series to the circuit to absorb part of the energy or parallel to the source to protect it from overvoltage when the load is switched off;

- load resistors to create an artificial load from generators and other sources; they are used to test electrical apparatus;

- heating resistors for heating the environment or apparatus at low temperatures;

- grounding resistors connected between ground and the neutral point of the generator or transformer to limit short-circuit currents to ground and possible surges during grounding;

- setting resistors to set a certain value of current or voltage in energy receivers.

The start, stop, discharge and ground resistors are designed primarily for short-term operation and should have as long a warm-up time as possible.

There are no special requirements for the stability of these resistors. All other resistors operate primarily in continuous operation and require the necessary cooling surface. The resistance of these resistors must be stable within the specified limits.

Depending on the material of the wire, metal, liquid, carbon and ceramic resistors are distinguished. V industrial electric drive most common metal resistors. Ceramic resistors (with non-linear resistance) are widely used in high voltage arresters.

Depending on the material of the wire, metal, liquid, carbon and ceramic resistors are distinguished. V industrial electric drive most common metal resistors. Ceramic resistors (with non-linear resistance) are widely used in high voltage arresters.

Resistor source material

In order to reduce the overall dimensions of the starting resistors, the specific resistance of the material used for its manufacture should be as high as possible. Allowable operating temperature of the material, it should also be as large as possible to reduce the weight of the material and the required cooling surface.

In order for the resistance of the resistor to depend as little as possible on the temperature, temperature coefficient of resistance (TCS) resistor should be as small as possible. Resistor material intended for operation in air must not corrode or must form an opposing protective film.

There is little steel electrical resistance… In the air, steel oxidizes intensively and therefore it is used only in rheostats filled with transformer oil. In this case, the working temperature of the steel is determined by the heating of the transformer oil and does not exceed 115 ° C.

Due to the high TCR value, steel is not applicable for stable resistance resistors. The only advantage of steel is its cheapness.

Electrical cast iron has a significantly higher electrical resistivity and significant TCR than steel. The working temperature of cast iron reaches 400 ° C... Cast iron resistors usually have a zigzag shape. Due to the fragility of cast iron, the required mechanical strength of the starting resistor elements is achieved by increasing their cross-section. Therefore, cast iron resistors are suitable for operation at high currents and powers.

Due to insufficient resistance to mechanical influences (vibrations, shocks), cast iron resistors are used only in stationary installations.

Specific electrical resistance sheet electrical steel due to the addition of silicon, it is almost three times higher than that of ordinary steel. Steel resistors have a zigzag shape and are obtained from sheet metal by stamping. Due to the large TCR, sheet steel is only used for starting resistors, usually mounted in transformer oil.

For resistors with increased resistance, constantan can be used, which does not corrode in air and has a maximum operating temperature of 500 ° C. The high resistance makes it possible to create constantan-based small resistors. Constantan is widely used in wire and tape form.

For the production of heating resistors, nichrome is mainly used, which has a high electrical resistance and operating temperature.

For resistors with high resistance resistance, manganin with an operating temperature of not more than 60 gr. S.

How starting resistors work

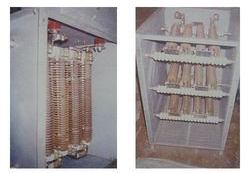

Wire or tape spiral resistors are made by winding on a cylindrical mandrel «turn for turn». The required gap between the turns is established by stretching the spiral and attaching it to the supporting insulators in the form of porcelain rollers.

The disadvantage of this design is low rigidity, due to which the contact of adjacent turns is possible, which requires a reduction in the operating temperature of the material (100 ° C for a constantan coil). Since the thermal capacity of such a resistor is determined only by the mass of the resistive material, the heating time of such resistors is small.

It is recommended to use resistors in the form of a spiral for long-term operation, since heat is dissipated from the entire surface of the wire or strip.

It is recommended to use resistors in the form of a spiral for long-term operation, since heat is dissipated from the entire surface of the wire or strip.

To increase the rigidity of the spiral, the wire can be wound on a ceramic tube-like frame with a spiral groove on the surface, preventing the turns from closing in on themselves. This design allows you to increase the operating temperature of the resistor from constantan to 500 ° C.Even in short-term operation, the frame more than doubles the heating constant due to its large mass.

At d <0.3 mm, the grooves on the surface of the frame are not made, and the insulation between the turns is created due to the scale (oxide film) formed when the wire is heated. To protect against mechanical damage, the wire is covered with heat-resistant glass enamel. Such tube resistors are widely used for controlling low-power motors, such as discharge, additional resistances in automation circuits, etc. The maximum power at which their temperature does not exceed the maximum permissible is 150 W, and the heating constant is 200 — 300 p. Due to the technological complexity of the production of large frames, these resistors are not used at high powers.

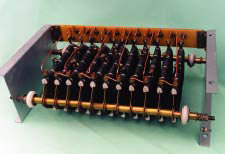

For starting motors up to 10 kW so-called wire or strip fields, sometimes called loop resistors. Porcelain or soapstone insulators are mounted on a steel plate. The constantan wire is wound in grooves on the surface of the insulators. For high current resistors, tape is used.

The coefficient of heat transfer in relation to the surface of the conductor is only 10-14 W / (m2- ° C). Therefore, the cooling conditions for such a resistor are worse than for a free helix. Due to the low mass of the insulators and the weak thermal contact of the conductor with the metal plate, the heating constant of the frame resistor is approximately the same as in the absence of the frame. The maximum allowable temperature is 300 °C.

Power dissipation reaches 350 watts. Usually several resistors of this type are assembled in one block.

For engines with a power of three to several thousand kilowatts, high-temperature resistors based on heat-resistant alloys 0X23Yu5 are used. In order to reduce the overall dimensions and obtain the necessary rigidity, the heat-resistant tape is wound around the rib and placed in the grooves that fix the position of the individual bends. Five 450 W resistors are installed in one block, which can be connected in parallel at high currents.

Thermal resistors have a low TCR and high mechanical stiffness, which is why they are widely used in devices exposed to high mechanical stress. These resistors have high thermal stability. Short-term heating up to 850 ° C is allowed with a long-term permissible temperature of 300 ° C.

Thermal resistors have a low TCR and high mechanical stiffness, which is why they are widely used in devices exposed to high mechanical stress. These resistors have high thermal stability. Short-term heating up to 850 ° C is allowed with a long-term permissible temperature of 300 ° C.

Cast iron resistors are widely used for motors with power from three to several thousand kilowatts.

At the maximum operating temperature of cast iron of 400 ° C, the nominal power of the resistors is taken based on a temperature of 300 ° C. The resistance of cast iron resistors is largely dependent on temperature, so they are used only as outputs.

A set of cast iron resistors are assembled in standard boxes using steel rods insulated from cast iron with micanite. If it is necessary to make taps for a resistor, they are made using special clamps that are installed between adjacent resistors connected in series.

A set of cast iron resistors are assembled in standard boxes using steel rods insulated from cast iron with micanite. If it is necessary to make taps for a resistor, they are made using special clamps that are installed between adjacent resistors connected in series.

The total power of the resistors installed in one box should not exceed 4.5 kW. During installation, the resistor boxes are mounted on top of each other. In this case, the heated air in the lower boxes washes the upper ones, impairing the cooling of the latter.

For critical electric drives, it is recommended to assemble the rheostat from standard boxes (without taps inside the box). If the resistor in the box is damaged, the circuit is quickly restored by replacing the defective box with a new one.

For critical electric drives, it is recommended to assemble the rheostat from standard boxes (without taps inside the box). If the resistor in the box is damaged, the circuit is quickly restored by replacing the defective box with a new one.

Since the temperature of the air near the resistor is high, the wires and busbars must either be sufficiently heat-resistant or not insulated at all.

Selection of resistors

The resistance of the starting resistor was chosen so that the starting current were limited and were not dangerous for the motor (transformer) and the electrical network. On the other hand, the value of this resistance should ensure the start of the motor for the required time.

After calculating the resistance, the calculation and selection of the heating resistor is carried out. The temperature of the resistor in any mode should not exceed the permissible for this design.