Contacts in electrical installations and electrical apparatus

The points of connection of the individual elements that make up any electrical circuit are called electrical contacts.

The points of connection of the individual elements that make up any electrical circuit are called electrical contacts.

Electrical contact — connection of wires that allow an electric current to be carried. Formation of current conductors contact are called contact bodies or positive and negative contacts, depending on which pole of the current source they are connected to.

Word "contact" means "touch", "touch". In an electrical system that combines various devices, machines, lines, etc., a huge number of contacts are used to connect them. The reliability of the equipment and the operation of the system largely depends on the quality of the contact connections.

Classification of electrical contacts

Electrical contacts are fixed and movable. Fixed contacts - all types of detachable and integral, designed for long-term connection of wires. Detachable contacts are made by clamps, bolts, screws, etc., integral — by soldering, welding or riveting.Movable contacts are divided into interrupted (contacts of relays, buttons, switches, contactors, etc.) and sliding (contacts between the collector and the brushes, contacts of switches, potentiometers, etc.).

The simplest type of electrical contact is a contact pair. A difficult type of contact is, for example, a contact forming a double parallel circuit closure or a double series closure (the latter is called coupling). The contact that switches the circuit when the device is actuated is called a changeover. A switching contact that breaks the circuit at the time of switching is called a switching contact, and not breaking the circuit at the time of switching is called a transient contact.

Depending on the form, electrical contacts are divided into:

-

point (top — plane, sphere — plane, sphere — sphere), which are commonly used in sensitive devices and relays that switch minor loads;

-

linear — occur at contacts in the form of cylindrical bodies and at brush Contacts;

-

planar — in high current switching equipment.

Usually the contacts are attached to flat springs, the so-called contact (made of nickel silver, phosphor and beryllium bronzes and less often steel), which are subject to high requirements regarding the constancy of their mechanical properties throughout the entire service life of the device, often calculated in tens and more than a million cycles. A set of springs, made in the form of a separate block, which are switched simultaneously, form a contact group (or pack).

Performance characteristics of electrical contact connections

The contact of the contacts does not occur over the entire surface, but only at individual points due to the roughness of the contact surface with any accuracy of its processing. Almost regardless of the type of contacts, the contact of the contact elements always takes place over small areas.

This is explained by the fact that the surface of the contact elements cannot be perfectly flat. Therefore, in practice, when the contact surfaces approach each other, they first come into contact with several protruding tips (points) and then, but with increasing pressure, deformation of the contact material occurs and these points turn into small playgrounds.

Lines of electric current passing from one contact to the other are attracted to these contact points. Therefore, the contact introduces some additional contact resistance Rk into the circuit connected by it.

If the contact surface is covered with a film, then R is increased. However, very thin films (up to 50 A) do not affect the contact resistance due to the tunneling effect. Thicker films may break under contact force or applied stress.

Electrical failure of contact films is called fritting. If the films are not destroyed, then Rk is mainly determined by the resistance of the films. Immediately after stripping a contact, as well as with sufficient contact force and voltage in the contact circuit, its resistance is determined mainly by the resistance of the contraction zones.

The greater the force applied to the contacts and the softer their material, the greater the total contact area of the contact surfaces and, accordingly, the less active electrical resistance at the junction (in the zone of the transition layer between the contact surfaces). This active resistance is called transient resistance.

Transient resistance — one of the main parameters of the quality of electrical contacts, as it characterizes the amount of energy absorbed in the contact compound, which turns into heat and heats the contact. The contact resistance can be strongly influenced by the way the contact surfaces are treated and their condition. For example, a rapidly forming oxide film on aluminum contacts can significantly increase the contact resistance.

When the current passes through the contacts, they are heated and the highest temperature is observed on the contact surface due to the presence of transition resistance. As a result of contact heating, resistance of the contact material and, accordingly, the resistance of the transition.

When the current passes through the contacts, they are heated and the highest temperature is observed on the contact surface due to the presence of transition resistance. As a result of contact heating, resistance of the contact material and, accordingly, the resistance of the transition.

In addition, an increase in the contact temperature promotes the formation of oxides on its surface, which increases the transient resistance even more significantly. And although with an increase in temperature, the contact material can soften somewhat, which is associated with an increase in the contact surface, in general, this process can lead to the destruction of the contacts or their welding. The latter, for example, is very dangerous for open contacts, because as a result, the device with these contacts will not be able to turn off the circuit. Therefore, for different types of contacts, a maximum permissible temperature with a long current flowing through them is determined.

To reduce heating, it is possible to increase the mass of the metal of the contacts and their cooled surface, which will enhance heat dissipation. To reduce the contact resistance, it is necessary to increase the contact pressure, choose the appropriate material and type of contacts.

For example, open contacts intended for external use are recommended to be made of materials that are slightly oxidizable, or to cover their surface with an anti-corrosion layer. Such materials include, in particular, silver, which can be used to coat contact surfaces.

Copper unbreakable contacts can be tinned (tinned surfaces are more difficult to oxidize). For the same purposes, the contact surfaces are covered with a lubricant, for example, petroleum jelly. Oil-immersed contacts are well protected against corrosion without other special measures. This is used in oil circuit breakers.

The operation of any electrical consists of 4 stages — open state, short circuit, closed state and opening, each of which affects the reliability of the contact.

In the open state, the external environment acts on the electrical contact, and as a result, films form on their surface.

In the closed state, when the contacts are pressed together and current passes through them, they heat up and deform; under some conditions, if the contacts overheat, welding may occur.

When the contacts close and open, bridge or discharge phenomena occur, accompanied by evaporation and transfer of metal contact, changing its surface. In addition, mechanical wear is possible. contacts resulting from bumping and sliding against each other.

As the contacts approach each other at very small distances, even at small power source voltages, the field gradient becomes so great that the dielectric strength of the gap breaks down and breakdown occurs. If there are foreign particles on the surface, especially those containing carbon, then when they come into contact, evaporation occurs and conditions for disposal are created.

Opening is usually the hardest part of the job. electrical contact Depending on the parameters of the circuit (R, L and C) and the magnitude of the applied voltage when opening, phenomena occur that cause wear Contacts. If the circuit voltage is greater than the voltage Upl, in where the metal of the contacts melts, after their separation, the contact force decreases and therefore the contact area, resistance and temperature will increase.

When the temperature exceeds the melting point of the metal, a molten metal bridge will form between the contact surfaces, gradually stretching and then breaking at the hottest point. The high temperature at the rupture of the bridge facilitates the initiation of ejection.

The bridge itself only exists in ohmic circuits at supply voltages below the arc voltage. If there is an inductance in the circuit, then the overvoltages caused by it at the moment of interruption of the current contribute to the appearance of a spark at currents below the arcing currents, and at currents above the arcing currents - arcs. Since there is almost always inductance in the circuit, bridges are in most cases accompanied by a discharge. Minimum spark voltage at the electrical outlet — 270-300 V.

Contacts of any type must provide not only continuous operation without unacceptable overheating under normal conditions, but also the necessary thermal and electrodynamic resistance in short-circuit mode. Movable breaking contacts should also not be destroyed by the high temperature of the electric arc that is formed when they are opened, and reliably closed without welding and melting when switched on for a short circuit. The measures discussed above also contribute to the fulfillment of these requirements.

Contacts of any type must provide not only continuous operation without unacceptable overheating under normal conditions, but also the necessary thermal and electrodynamic resistance in short-circuit mode. Movable breaking contacts should also not be destroyed by the high temperature of the electric arc that is formed when they are opened, and reliably closed without welding and melting when switched on for a short circuit. The measures discussed above also contribute to the fulfillment of these requirements.

Metal-ceramic contacts, which is a mixture of crushed copper powders with tungsten or molybdenum and silver with tungsten.

Such a compound simultaneously possesses good electrical conductivity due to the use of copper or silver and the high melting point due to the use of tungsten or molybdenum.

There is another way to eliminate the existing contradiction, which consists in the fact that materials with good electrical conductivity (silver, copper, etc.), as a rule, have a relatively low melting point, and refractory materials (tungsten, molybdenum) have a low electrical conductivity. This is the use of a double contact system consisting of operating and arcing contacts connected in parallel.

Working contacts are made of material with high electrical conductivity and arcing contacts — made of fire-resistant material. In normal mode, when the contacts are closed, most of the current flows through the working contacts.

When the circuit is de-energized, the operating contacts open first, followed by the arcing contacts.Therefore, in fact, the circuit is interrupted by arcing contacts, for which even the short-circuit current does not pose a great danger (for significant short-circuit currents, special arcing devices are additionally used).

When the circuit is de-energized, the operating contacts open first, followed by the arcing contacts.Therefore, in fact, the circuit is interrupted by arcing contacts, for which even the short-circuit current does not pose a great danger (for significant short-circuit currents, special arcing devices are additionally used).

When the circuit is switched on, the arcing contacts are closed first, followed by the operating contacts. Thus, the operating contacts do not actually break or close the circuit completely. This eliminates the danger of melting and welding.

To eliminate the possibility of spontaneous opening of contacts from electrodynamic efforts when short-circuit currents flow, the contact systems are designed so that the electrodynamic forces under these conditions provide additional contact pressure and prevent possible melting and welding of the contacts at the moment of switching on the short-circuit circuit, accelerated switching.

To eliminate the danger of a significant elastic impact on the contact surfaces, use pre-pressing of contacts with special springs... In this case, both a high switching speed and the elimination of possible vibrations are ensured, since the spring is pre-compressed and after touching contacts, the pushing force begins to grow not from zero, but from a certain specified value. mode, but also the required thermal and electrodynamic resistance in short-circuit mode.

Movable breaking contacts should also not be destroyed by the high temperature of the electric arc that is formed when they are opened, and reliably closed without welding and melting when switched on for a short circuit.The measures discussed above also contribute to the fulfillment of these requirements.

Contacts made of metal ceramic, which is a mixture of crushed copper powders with tungsten or with molybdenum and silver with tungsten, are particularly resistant to the destructive action of an electric arc.

Such a compound has both good electrical conductivity due to the use of copper or silver and a high melting point due to the use of tungsten or molybdenum.

Basic designs of contacts in electrical installations and electrical devices

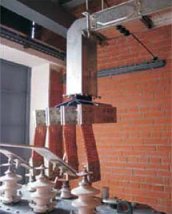

The construction of fixed (rigid) unbreakable contact joints must ensure reliable clamping of the contact surfaces and minimal contact resistance. It is better to connect the tires with several smaller bolts than with one large one, as this provides more points of contact. When connecting the tires, the contact resistance is lower than when using bolts, when drilling holes in the tires is necessary. The high quality of the contact connection is ensured by the welding of the busbars.

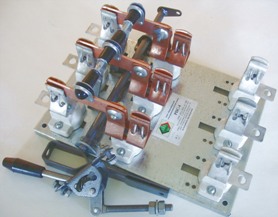

Movable breaking contacts — a basic element of switching devices... In addition to the general requirements for all contacts, they must have arc resistance, the ability to reliably turn on and off the circuit in the event of a short circuit, as well as withstand a certain number of switching operations and shutdown without mechanical damage.

The simplest contact of this type is a flat cutting contact. When engaged, the movable blade enters between the fixed spring-loaded jaws. The disadvantage of such a flat contact is that the contact of the contact surfaces occurs at several points due to the irregularities of these surfaces.

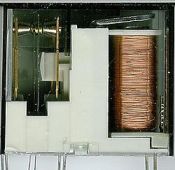

To obtain a linear contact, semi-cylindrical protrusions are stamped on the knife strips, and to increase the pressure, the strips are compressed with a steel clamp with a spring. Break contacts are most often used in circuit breakers and disconnectors.

The contact part of the self-aligning finger contact is made in the form of fingers, in the plate — in the form of plates, in the end — in the form of a flat top, in the socket — in the form of lamellas ( segments), in the brush — in the form of brushes of elastic, thin copper or bronze plates.

The specified contact parts (parts) in a number of designs can change, within limited limits, their position relative to the fixed contacts. Flexible current-carrying connections are provided for their reliable electrical connection.

The stability of the breaking contacts and the required compressive force are usually achieved by means of leaf or coil springs.

Finger contacts and contacts are used in devices with voltages above 1000 V for various currents as operating and arcing contacts, and flat contacts are used as operating contacts. End contacts are used for voltages 110 kV and higher, for currents not exceeding 1 — 1.5 kA as operating and arcing contacts. Brush contacts are used in devices for various voltages and significant currents, but only as working contacts, since an electric arc can damage relatively thin brushes.