Current overloads and their effect on the operation and service life of electric motors

Analysis of asynchronous motor failures shows that the main cause of their failure is insulation breakdown due to overheating.

Analysis of asynchronous motor failures shows that the main cause of their failure is insulation breakdown due to overheating.

Overloading of an electrical product (device) — exceeding the actual value of the power or current of an electrical product (device) over the rated value. (GOST 18311-80).

The heating temperature of the windings of the electric motor depends on the thermal characteristics of the motor and the environmental parameters. Part of the heat generated in the motor goes to heat the coils, and the rest is released into the environment. The heating process is affected by such physical parameters as heat capacity and heat dissipation.

Depending on the thermal condition of the electric motor and the surrounding air, the degree of their influence may vary.If the temperature difference between the motor and the environment is small and the released energy is significant, then the main part of it is absorbed by the winding, stator and rotor steel, the motor housing and its other parts. There is an intense rise in the temperature of the insulation... With heating, the effect of heat exchange is manifested more and more. The process is established after reaching an equilibrium between the heat generated and the heat released to the environment.

Increasing the current above the permissible value does not immediately lead to an emergency condition... It takes some time for the stator and rotor to reach their extreme temperature. Therefore, there is no need for the protection to react to every overcurrent. She should switch off the machine only when there is a danger of rapid deterioration of the insulation.

From the point of view of insulation heating, the magnitude and duration of current flow exceeding the nominal value are of great importance. These parameters depend primarily on the nature of the technological process.

Overloading of an electric motor of technological origin

Overloading of the electric motor caused by a periodic increase in torque on the shaft of the driven machine. In such machines and installations, the power of the electric motor changes all the time. It is difficult to observe a long period of time during which the current remains unchanged in magnitude. Short-term large moments of resistance periodically appear on the motor shaft, creating current surges.

Overloading of the electric motor caused by a periodic increase in torque on the shaft of the driven machine. In such machines and installations, the power of the electric motor changes all the time. It is difficult to observe a long period of time during which the current remains unchanged in magnitude. Short-term large moments of resistance periodically appear on the motor shaft, creating current surges.

Such overloads usually do not cause overheating of the motor windings, which have a relatively high thermal inertia.However, with sufficiently long duration and repeated repetition, dangerous heating of the electric motor… Defense must "distinguish" between these regimes. It should not react to short-term load shocks.

Other machines may experience relatively small but long-term overloads. The motor windings gradually heat up to a temperature close to the maximum allowable value. Usually, the electric motor has a certain reserve of heating and small overcurrents, despite the duration of the action, cannot create a dangerous situation. In this case, the shutdown is not necessary. In this way, here too, the motor protection must "distinguish" between dangerous and non-dangerous overloads.

Emergency overloads of the electric motor

with the exception of overloading of technological origin, perhaps emergency overloads that occurred for other reasons (damage in the power supply line, jamming of working devices, voltage drop, etc.). They create particular modes of operation of an induction motor and offer their requirements for safety devices... Consider the behavior of an induction motor in typical emergency modes.

Overloads in continuous operation with constant load

Electric motors are usually chosen with a certain power reserve. Also, most of the time the machines are running under load. As a result, the motor current is often well below the rated value. Overloads occur, as a rule, in the case of technological violations, breakdowns, jamming and jamming in the working machine.

Machines such as fans, centrifugal pumps, conveyor belts and screws have a quiet, constant or slightly varying load.Short-term changes in the material flow have practically no effect on the heating of the electric motor. They can be ignored. It is another matter if the violations of normal working conditions remain for a long time.

Most electric drives have a certain power reserve. Mechanical overloads primarily cause damage to machine parts. Given the random nature of their occurrence, it cannot be certain that under certain circumstances the electric motor will also be overloaded. For example, this can happen with screw motors. Changes in the physical and mechanical properties of the transported material (moisture, particle size, etc.) are immediately reflected in the power required to move it. The protection should shut down the electric motor in the event of an overload causing dangerous overheating of the windings.

From the point of view of the influence of long-term overcurrents on the insulation, two types of overloads should be distinguished: relatively small (up to 50%) and large (more than 50%).

The effect of the former does not appear immediately, but gradually, while the effects of the latter appear after a short time. If the temperature rise above the permissible value is small, the aging of the insulation occurs slowly. Small changes in the structure of the insulating material accumulate gradually. As the temperature increases, the aging process accelerates significantly.

I think that overheating above the permissible for every 8 — 10 ° C halves the service life of the insulation of the motor windings.Therefore, overheating by 40 ° C reduces the life of the insulation 32 times! Although this is a lot, it shows up after many months of work.

At high overloads (more than 50%), the insulation quickly collapses under the influence of high temperatures.

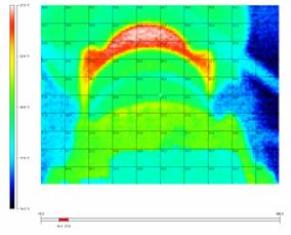

To analyze the heating process, we will use a simplified engine model. An increase in current leads to an increase in variable losses. The coil starts to heat up. The insulation temperature changes according to the graph in the figure. The rate of steady state temperature rise depends on the magnitude of the current.

Some time after an overload occurs, the temperature of the windings reaches the value permissible for the given class of insulation. At high G-forces it will be shorter, at low G-forces it will be longer. Thus, each overload value will have its own allowable time that can be considered safe to isolate.

The dependence of the permissible duration of the overload on its magnitude is called the overload characteristic of the electric motor... Thermophysical properties electric motors of various types have some differences and their characteristics also differ. One of these features is shown in the figure with a solid line.

Motor overload characteristic (solid line) and desired protection characteristic (dashed line)

From the given characteristics, we can formulate one of the main requirements to current-dependent overload protection… It should be raised depending on the magnitude of the overload.This makes it possible to exclude false alarms with harmless current spikes, occurring for example when the engine is started. The protection should work only when it falls into the zone of unacceptable current values and the duration of its flow. Its desired characteristic, shown in the figure with a dashed line, must always lie below the overload characteristic of the motor.

The operation of the protection is affected by a number of factors (imprecision of settings, dispersion of parameters, etc.), as a result of which deviations from the average values of the response time are observed. Therefore, the dashed line on the graph should be seen as some kind of average characteristic. In order not to cross the characteristics as a result of the action of random factors, which will lead to incorrect stopping of the engine, it is necessary to provide a certain margin. In fact, one should work not with a separate characteristic, but with a protective zone, taking into account the distribution of the reaction time of the protection.

In terms of exact motor protection actions, it is desirable that both characteristics are as close as possible to each other. This will avoid unnecessary tripping at close to allowable overloads. However, if there is a large spread of both characteristics, this cannot be achieved. In order not to fall into the zone of unacceptable current values in case of random deviations from the calculated parameters, it is necessary to provide a certain margin.

In terms of exact motor protection actions, it is desirable that both characteristics are as close as possible to each other. This will avoid unnecessary tripping at close to allowable overloads. However, if there is a large spread of both characteristics, this cannot be achieved. In order not to fall into the zone of unacceptable current values in case of random deviations from the calculated parameters, it is necessary to provide a certain margin.

The protective characteristic must be located at a certain distance from the overload characteristic of the motor to exclude their mutual crossing.But this leads to the loss of the accuracy of the motor protection action.

In the region of currents close to the nominal value, an uncertainty zone appears. When entering this zone, it is impossible to say for sure whether the protection will work or not.

This drawback is absent in protection operating depending on the winding temperature... Unlike the overcurrent protection, it acts depending on the cause of the aging of the insulation, its heating. When a temperature dangerous to the winding is reached, it shuts down the motor, regardless of the reason that caused the heating. This is one of the main advantages protection from temperature.

However, the lack of overcurrent protection should not be overstated. The fact is that motors have a certain current reserve. The rated current of the motor is always lower than the current at which the temperature of the windings reaches the permissible value. It is established, guided by economic calculations. Therefore, at rated load, the temperature of the motor windings is below the permissible value. Due to this, a thermal reserve of the engine is created, which to some extent compensates for the lack thermal relays.

Many factors on which the thermal condition of insulation depends have random deviations. In this regard, the specification of characteristics does not always give the desired result.

Overloads in variable continuous operation

Some working bodies and mechanisms create loads that vary over a wide range, such as in crushing, grinding and other similar operations. Here, periodic overloads are accompanied by underloads to idle.Any increase in current, taken separately, does not lead to a dangerous rise in temperature. However, if there are many and they are repeated often enough, the effect of the increased temperature on the insulation quickly accumulates.

Some working bodies and mechanisms create loads that vary over a wide range, such as in crushing, grinding and other similar operations. Here, periodic overloads are accompanied by underloads to idle.Any increase in current, taken separately, does not lead to a dangerous rise in temperature. However, if there are many and they are repeated often enough, the effect of the increased temperature on the insulation quickly accumulates.

The heating process of the electric motor at a variable load differs from the heating process at a constant or slightly variable load. The difference is manifested both in the course of temperature changes and in the nature of heating of individual parts of the machine.

As the load changes, so does the temperature of the windings. Due to the thermal inertia of the engine, temperature fluctuations are less widespread. At a sufficiently high frequency of loading, the temperature of the windings can be considered practically unchanged. This will be equivalent to continuous operation with constant load. At low frequency (of the order of hundredths of a hertz and lower) temperature fluctuations become noticeable. Periodic overheating of the winding can shorten the life of the insulation.

With large load fluctuations at low frequency, the motor is constantly in a transient process. Its coil temperature changes after load fluctuations. Since individual parts of the machine have different thermophysical parameters, each of them heats up in its own way.

The course of thermal transients under variable load is a complex phenomenon and is not always subject to calculation. Therefore, the temperature of the motor windings cannot be estimated from the current flowing at any given time. Due to the fact that the individual parts of the electric motor are heated in different ways, the heat passes from one part to another in the electric motor.It is also possible that after switching off the electric motor, the temperature of the stator windings will rise due to the heat supplied by the rotor. Thus, the magnitude of the current may not reflect the degree of heating of the insulation. It should also be borne in mind that in some modes the rotor will heat up more intensively and cool down less than the stator.

The complexity of the heat transfer processes makes it difficult to control the heating of the motor... Even the direct measurement of the temperature of the windings can give an error under some conditions. The fact is that in unstable heat processes, the heating temperature of different parts of the machine can be different, and the measurement at one time cannot give a true picture. However, coil temperature measurement is more accurate than other methods.

Periodic work can be referred to the most unfavorable from the point of view of the action of the protection. Periodic inclusion in work implies the possibility of short-term motor overload. In this case, the magnitude of the overload must be limited by the condition of heating the windings, which does not exceed the permissible value.

The protection "monitoring" the heating state of the coil must receive the corresponding signal. Since current and temperature may not correspond to each other in transient conditions, protection based on current measurement cannot perform its role properly.