What are the types and types of circuit breakers in electrical networks

The main difference between these switching devices from all other similar devices is the complex combination of capabilities:

The main difference between these switching devices from all other similar devices is the complex combination of capabilities:

1. to maintain the nominal load in the system for a long time due to the reliable transmission of powerful currents of electricity through its contacts;

2. to protect operational equipment from accidental damage in the electrical circuit by quickly disconnecting the power supply from it.

Under normal equipment operating conditions, the operator can manually switch the load with the circuit breakers, providing:

-

different power schemes;

-

change the network configuration;

-

withdrawing the equipment from operation.

Emergency situations in electrical systems occur immediately and spontaneously. A person is not able to quickly react to his appearance and take measures to eliminate them. This function is assigned to automatic devices built into the circuit breaker.

In electricity, the division of electrical systems by type of current is accepted:

-

permanent;

-

alternating sinusoidal.

In addition, there is a classification of equipment according to the magnitude of the voltage for:

-

low voltage — less than a thousand volts;

-

high voltage — everything else.

For all types of these systems, their own circuit breakers designed for repeated operation have been created.

AC circuits

This category of keys has a huge assortment of models produced by modern manufacturers. It is classified by mains voltage and current load.

Electrical equipment up to 1000 volts

According to the power of the transmitted electricity, automatic switches in alternating current circuits are conditionally divided into:

1. modular;

2. in a molded case;

3. power air.

Modular designs

The specific design in the form of small standard modules with a width multiple of 17.5 mm determines their name and design with the possibility of mounting on a Din-rail.

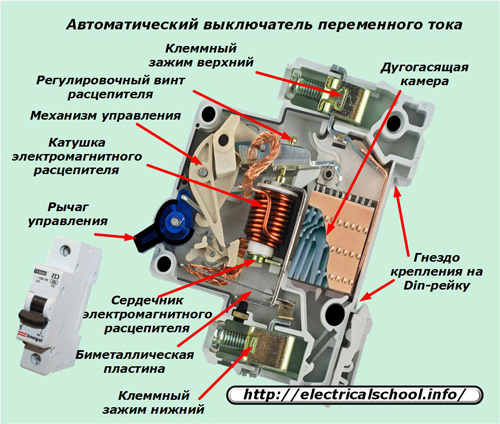

The internal structure of one of these circuit breakers is shown in the photo. Its body is made entirely of a durable dielectric material that eliminates electric shock to a person.

The supply and output wires are connected to the upper and lower terminal block respectively. For manual control of the switch state, a lever with two fixed positions is installed:

-

the upper one is designed to supply current through a closed power supply contact;

-

below — provides a break in the power circuit.

Each of these machines is designed for continuous operation at a certain value rated current (Yin). If the load becomes larger, the power contact is broken. For this purpose, two types of protection are placed inside the box:

1. thermal release;

2. current interrupt.

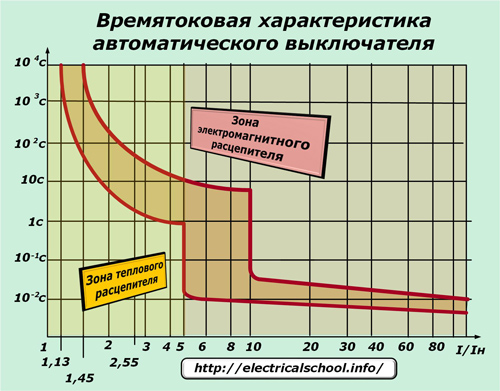

The principle of their operation makes it possible to explain the time current characteristic, which expresses the dependence of the protection operation time on the load or fault current passing through it.

The graph shown in the photo is given for one specific circuit breaker when the limit operating zone is selected at 5 ÷ 10 times the rated current.

In case of initial overload, thermal release from bimetallic plate, which with an increased current gradually heats up, bends and acts on the shutdown mechanism not immediately, but with some time delay.

Thus, it allows small overloads associated with a short-term connection of users to self-remove and eliminate unnecessary shutdowns. If the load provides critical heating of the wiring and insulation, the power contact is broken.

When an emergency current occurs in the protected circuit, capable of burning the equipment with its energy, then an electromagnetic coil comes into action. With an impulse, due to the increase in load that has occurred, it throws the core on the trip mechanism to immediately stop the out-of-bounds mode.

The graph shows that the higher the short-circuit currents, the faster they are tripped by the electromagnetic release.

The household automatic steam protector works on the same principles.

When large currents are interrupted, an electric arc is created, the energy of which can burn the contacts. To eliminate its effect, an arc extinguishing chamber is used in circuit breakers, which divides the arc discharge into small streams and extinguishes them due to cooling.

Multiple cutouts of modular structures

Magnetic trips are tuned and matched to work with specific loads because they create different transients when they start. For example, when switching on various lighting fixtures, the short-term inrush current due to the changing resistance of the filament can approach three times the nominal value.

Therefore, for the group of sockets of apartments and lighting circuits, it is customary to choose automatic switches with a current-time characteristic of the «B» type. That's 3 ÷ 5 inches.

Induction motors, when rotating a driven rotor, cause larger overload currents. For them, choose machines with characteristic «C» or — 5 ÷ 10 In. Due to the created reserve in time and current, they allow the motor to rotate and are guaranteed to enter the operating mode without unnecessary shutdowns.

In industrial production, on metal cutting machines and mechanisms, there are loaded drives connected to motors that create more increased overloads. For such purposes, automatic switches with characteristic «D» with a rating of 10 ÷ 20 In are used. They have proven themselves well when working in circuits with active-inductive loads.

In addition, machines have three more types of standard time-current characteristics that are used for special purposes:

1. "A" — for long wiring with an active load or protection of semiconductor devices with a value of 2 ÷ 3 In;

2. "K" — for expressed inductive loads;

3. «Z» — for electronic devices.

In the technical documentation of different manufacturers, the limit value for the last two types may differ slightly.

Molded box circuit breakers

This class of devices can switch higher currents than modular designs. Their load can reach values up to 3.2 kiloamperes.

They are produced according to the same principles as modular structures, but taking into account the increased requirements for transmitting the increased load, they try to give them relatively small dimensions and high technical quality.

These machines are designed for safe operation in industrial facilities. According to the value of the nominal current, they are conditionally divided into three groups with the ability to switch loads up to 250, 1000 and 3200 amperes.

Structural design of their body: three- or four-pole models.

Power air switches

They work in industrial installations and withstand very heavy currents up to 6.3 kiloamperes.

These are the most complex devices for switching low voltage devices. They are used for operation and protection of electrical systems as input and output devices for high power distribution systems and for connecting generators, transformers, capacitors or powerful electric motors.

A schematic representation of their internal structure is shown in the photo.

Here double disconnection of the supply contact is now used and arc extinguishing chambers with grids are installed on each side of the disconnection.

The algorithm of operation includes the closing coil, the closing spring, the motor drive of the spring charge and the automation elements. A current transformer with protective and measuring coil is integrated to monitor the current loads.

Electrical equipment over 1000 volts

Circuit breakers for high-voltage equipment are very complex technical devices and are made strictly individually for each voltage class. They are commonly used of transformer substations.

Requirements are imposed on them:

-

high reliability;

-

security;

-

productivity;

-

ease of use;

-

relative silence during operation;

-

optimal price.

The loads that break high voltage circuit breakers in the event of an emergency stop accompanied by a very strong arc. Various methods are used to extinguish it, including breaking the circuit in a special environment.

This switch includes:

-

contact system;

-

arc extinguishing device;

-

live parts;

-

insulated housing;

-

drive mechanism.

One of these switching devices is shown in the photo.

For high-quality operation of the circuit in such structures, in addition to the operating voltage, consider:

-

the nominal value of the load current for its reliable transmission in the on state;

-

maximum short-circuit current at eff. value that the shutdown mechanism can withstand;

-

admissible component of the aperiodic current at the time of circuit failure;

-

auto reclose capabilities and two AR cycles.

According to the methods of extinguishing the arc during tripping, switches are classified into:

-

butter;

-

vacuum;

-

air;

-

SF6 gas;

-

autogas;

-

electromagnetic;

-

autopneumatic.

For reliable and convenient operation, they are equipped with a drive mechanism that can use one or more types of energy or their combinations:

-

raised spring;

-

lifted load;

-

compressed air pressure;

-

electromagnetic pulse from the solenoid.

Depending on the conditions of use, they can be created with the ability to work at voltages from one to 750 kilovolts inclusive. Naturally, they have a different design. dimensions, automatic and remote control capabilities, protection settings for safe operation.

Auxiliary systems of such circuit breakers can have a very complex branched structure and be located on additional panels in special technical buildings.

DC circuits

These networks also have a huge number of switches with different capabilities.

Electrical equipment up to 1000 volts

Modern DIN-rail mountable modular devices are massively presented here.

They successfully complement the classes of old machines of this type AP-50, AE and the like, which were fixed on the walls of the panels with screw connections.

DC modular designs have the same structure and operating principle as their AC counterparts. They can be performed by one or several units and are selected according to the load.

Electrical equipment over 1000 volts

High voltage DC circuit breakers are used in electrolysis plants, metallurgical industrial facilities, railway and urban electrified transport and power plants.

The main technical requirements for the operation of such devices correspond to their alternating current counterparts.

Hybrid circuit breaker

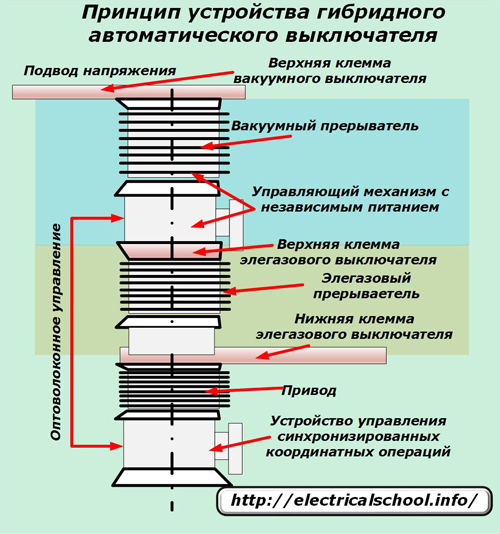

Scientists from the Swedish-Swiss company ABB managed to develop a high-voltage DC circuit breaker that combines two power structures in its device:

1.SF6 gas;

2. vacuum.

It is called hybrid (HVDC) and uses the technology of sequential arc extinguishing in two media at the same time: sulfur hexafluoride and vacuum. For this purpose, the following device is assembled.

Voltage is applied to the top bus of the hybrid vacuum circuit breaker and removed from the bottom bus of the SF6 circuit breaker.

The power supplies of the two switching devices are connected in series and controlled by their separate drives. In order for them to work simultaneously, a synchronized coordinate operation control device was created, which transmits commands to an independently powered control mechanism via an optical channel.

Thanks to the use of high-precision technologies, the designers were able to achieve coordination of the actions of the drives of the two drives, which fits into a time interval of less than one microsecond.

The circuit breaker is controlled by a relay protection unit built into the power line through a repeater.

The hybrid circuit breaker made it possible to significantly increase the efficiency of composite SF6 and vacuum structures by exploiting their combined characteristics. At the same time, it was possible to realize the advantages over other analogues:

1. the ability to reliably turn off short-circuit currents at high voltage;

2. the possibility of small efforts to carry out the switching of the power elements, which made it possible to significantly reduce the dimensions and, accordingly, the price of the equipment;

3. the availability of meeting different standards for creating structures working as part of a separate circuit breaker or compact devices of one substation;

4.the ability to eliminate the effects of rapidly increasing stress during recovery;

5. Ability to form a basic module for working with voltages up to 145 kilovolts and more.

A distinctive feature of the design is the ability to break an electrical circuit in 5 milliseconds, which is almost impossible to do with power devices of another design.

The hybrid circuit breaker was ranked among the top ten developments of the year by the MIT (Massachusetts Institute of Technology) Technology Review.

Other electrical equipment manufacturers are engaged in similar research. They also achieved certain results. But ABB is ahead of them in this matter. Its management believes that AC transmission is causing its heavy losses. These can be greatly reduced by using direct voltage high voltage circuits.