Application of surge arresters (limiters)

Purpose of Surge Protectors (SPN)

Surge arresters (SPDs) are high voltage devices designed to protect the insulation of electrical equipment from atmospheric and switching surges.

Unlike traditional valve spark gaps and silicon carbide resistors /, they do not contain spark gaps and consist only of a column of non-linear zinc oxide resistors enclosed in a polymer or porcelain coating.

Zinc oxide resistors allow the use of surge arresters for deeper surge limitation than valves and are able to withstand the operating voltage of the network without time limit. The polymer or porcelain coating provides effective protection of the resistors from the environment and safe operation.

The dimensions of the restrictors and their weight are significantly smaller compared to the valves.

Normative documents for the use of surge arresters (surge arrester)

Currently, the following regulatory documents exist, which to one degree or another address the issues of protection of power installations from overvoltage:

Instructions for the device for lightning protection of buildings and facilities (RD 34.21.122-87);

Temporary instructions for the use of RCDs in electrical installations of buildings (Letter of the State Energy Supervision Agency of Russia dated 04.29.97 No. 42-6 / 9-ET, section 6, point 6.3);

GOST R 50571.18-2000, GOST R 50571.19-2000, GOST R 50571.20-2000.

Specifications for surge arresters (surge arresters)

The highest continuous operating voltage (Uc) is the highest effective value of alternating current voltage that can be supplied to the arrester terminals without time limitation.

Rated voltage is a normative parameter in accordance with IEC99-4 that defines the value of alternating voltage that an arrester must withstand for 10 seconds during operational tests.

Conduction current is the current flowing through the arrester under the influence of the voltage applied to the arrester terminals under operating conditions. This current consists of active and capacitive components and its value is several hundred microamperes. This operating current is used to evaluate the quality of the surge.

The resistance of the arrester to slowly changing voltage is the ability of the arrester to withstand the increased voltage level of the power frequency without breakdown for a given time. This voltage value is used to set the protective shutdown of the arrester after a certain time.

The rated discharge current is the current according to which the protective level of an arrester in lightning mode is classified at an impulse of 8/20 μs.

The rated switching surge current is the current at which the protection level is rated for switching surges with 30/60 μs pulse parameters.

The discharge current limit is the peak value of a lightning discharge current of 4/10 μs, which is used to test the strength of an arrester in the event of a direct lightning strike at the installation site.

The current carrying capacity is the standard for the service life of the arrester for the entire service life in the most unfavorable cases of limiting both lightning and switching surges. The equivalent of the throughput is the line discharge class, which according to IEC99-4 has 5 classes.

Short-circuit resistance in an arrester is the ability of a damaged arrester to withstand the short-circuit currents in the network at the arrester location without exploding the tire.

Design of Surge Protectors (Surge)

Most of the major electrical product manufacturers in the development and production of surge protectors use the same design solutions, technologies and design as in the production of other cable products. This refers to overall dimensions, housing material, applied technical solutions for installing the product in the user's electrical installation, appearance and other parameters. In addition to the design of surge arresters, the following requirements may be imposed:

The housing of the device must be made in accordance with the requirements for protection against direct contact (protection class at least IP20);

There is no risk of a fire protection device or a short circuit in the line in the event of an overload failure;

Availability of a simple and reliable indication of damage, the possibility of connecting a remote alarm;

Easy on-site installation (standard DIN rail mounting, compatibility with automatic fuses from most European manufacturers: ABB, Siemens, Schrack, etc.)

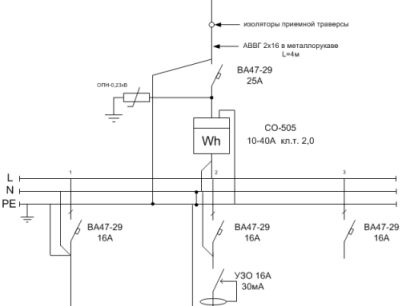

An example of arrester installation

How to protect yourself from overvoltage

Protect yourself and your equipment (using differential protection devices)

How to prevent insulation failure of the induction winding of the electric motor stator

How to turn on a three-phase electric motor in a single-phase network without rewinding