Lead-free soldering technologies: SAC solders and conductive adhesives

For decades, lead-tin solder has been used to secure electronic components, solder printed circuit boards. The serious adverse health effects associated with the use of lead have spawned a vigorous effort in the electronics industry to find substitutes for lead solder. Scientists now believe they have discovered some promising possibilities: alternative solders made of alloys and polymer compositions known as conductive glue.

For decades, lead-tin solder has been used to secure electronic components, solder printed circuit boards. The serious adverse health effects associated with the use of lead have spawned a vigorous effort in the electronics industry to find substitutes for lead solder. Scientists now believe they have discovered some promising possibilities: alternative solders made of alloys and polymer compositions known as conductive glue.

Soldering is the backbone of electronics manufacturing. Lead was perfect as solder. Arguably, all electronics are designed around the melting point and physical properties of lead. I lead — plastic material, unbreakable and therefore easy to work with. When lead is combined with tin in the correct ratio (63% tin and 37% lead), the alloy has a low melting point of 183 degrees Celsius, which is another advantage.

When working at low temperature soldering processes better control is exercised over the joint production technology, while the welded elements are not sensitive to the smallest temperature deviations. Low temperatures also mean less stress on equipment and materials (PCBs and components) that heat up during assembly, and higher productivity in electronics manufacturing due to shorter heat-up and cool-down times.

The main incentive for the electronics industry in Europe to start using lead-free solders was a lead ban imposed by the European Union. Under the Hazardous Substances Directive restriction, lead had to be replaced by other substances by 1 July 2006 (the directive also bans mercury, cadmium, hexavalent chromium and other toxic substances).

All electronic components that contain lead are now banned in Europe. In this regard, sooner or later Russia will also have to switch to lead-free connection technologies in electronics.

Lead, from an environmental perspective, is not a problem in itself as long as it is contained in electronic equipment. However, when electronic components end up in landfills, lead can wash out of the landfill soil and into drinking water. The risk increases in countries where e-waste is imported en masse.

In China, for example, workers without protective equipment, including many children, are engaged in disassembling (soldering) recyclable materials from electronic components. In Russia, even today, lead solders are very common in non-automated electronics manufacturing.

The harmful effects of lead on human health, even at low levels, are well known: disorders of the nervous and digestive systems, especially pronounced in children, and the ability of lead to accumulate in the body, causing severe poisoning.

Electronics manufacturers began looking for alternative solders as early as 1990, when the now-ratified proposals to ban lead in the US were discussed. Electronics industry experts reviewed 75 alternative solders and whittled that list down to half a dozen.

In the end, a combination of 95.5% tin, 3.9% silver and 0.6% copper, also known as SAC grade solder (abbreviation of the first letters of the elements Sn, Ag, Cu), was chosen, providing greater reliability and ease of operation as a replacement for lead-lead solder. The melting point of SAC solder is 217 degrees, it is close to the melting point of conventional lead-lead solder (183 ... 260 degrees).

Screwless solder

SAC solders are widely used in the offshore industry today. Introducing new types of solder has taken a lot of effort on the part of electronics companies. Experts were concerned that at the initial stage of the introduction of lead-free solders, an increase in the failure rate of electronic products was possible.

In this regard, equipment that is involved in the life and safety of people, for example, electronics for hospitals, is produced using old technologies. The ban on lead solder also does not yet apply to mobile phones and digital cameras. There is also no definitive answer about the complete safety of the new silver-based solders — this metal is toxic to aquatic animals.

Unleaded flux

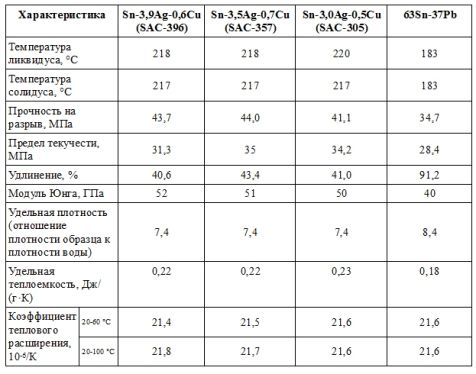

Section. 1.Comparative characteristics of some SAC solders and tin-lead solder

A more daring experimental alternative to soldering lead solder is the use of electrically conductive adhesives... These are polymers, silicone or polyamide containing small flakes of metals, most often silver. Polymers glue electronic components and metal flakes conduct electricity.

These adhesives offer a wide range of advantages. The electrical conductivity of silver is very high and its electrical resistance is low. The temperature required to apply PCB assembly adhesives is much lower (150 degrees) than that required for lead-based solders. Therefore, firstly, electricity is saved, and secondly, electronic components are exposed to less heating, as a result of which their reliability increases.

Finnish research presented in 2000 at the 4th International Conference on Adhesives and Coating Technologies in the Electronics Industry shows that electrically conductive adhesives form even stronger bonds than traditional solders.

If scientists manage to increase the electrical conductivity of such adhesives, they can completely replace traditional solders. So far, these materials have been used for a small number of small conducting compounds amperage — for soldering liquid crystal displays and crystals. Research in this area is focused on the addition of dicarboxylic acid molecules, which provide a connection between the silver flakes and accordingly increase the electrical conductivity of the material.

A serious problem with electrically conductive adhesives is possible destruction when components are heated above 150 degrees.There are other concerns about electrically conductive adhesives. Over time, the ability of adhesives to conduct electricity decreases. And the water that the polymer can absorb will cause corrosion. When dropped from a height, adhesives exhibit brittle properties, and rubber-doped polymers will be developed to improve their elasticity in the future. Insufficient knowledge of this material may further reveal other, as yet unknown, problems.

Conductive adhesives are expected to be used in consumer electronics (mobile phones and digital cameras) where reliability is not critical, such as medical and avionics.