Paper Paper Insulation - Uses, Advantages and Disadvantages

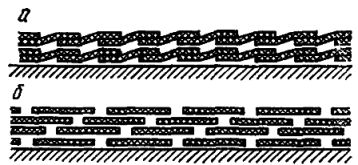

Oil paper insulation consists of layers of oil-impregnated paper and oil layers filling the gaps between the paper layers. The paper insulation layer can be constructed from solid sheets of paper, such as in bag or roll capacitor insulation, or by winding paper tape with positive or negative overlap (Figure 1).

Oil paper insulation consists of layers of oil-impregnated paper and oil layers filling the gaps between the paper layers. The paper insulation layer can be constructed from solid sheets of paper, such as in bag or roll capacitor insulation, or by winding paper tape with positive or negative overlap (Figure 1).

Positive overlap tape insulation is used to isolate turns power transformers, isolation current transformers, voltage and other devices. The tape is wound with at least a full overlap manually or on a machine with the maximum possible tension, ensuring a high adhesion density of the layers.

Electrical power cables are coiled with a gap (negative overlap) to provide the necessary cable flexibility. The width of the gap is proportional to the width of the tape and is usually 1.5 - 3.5 mm with a tape width of 15 - 30 mm, the thickness of the paper tapes is 14 - 120 microns.They tend to roll in such a way that to avoid gap overlap, the allowable number of matching gaps is normalized because oil layers of significant thickness are areas of reduced electrical strength.

Rice. 1. Oil paper insulation with positive and negative overlap

Oil paper insulation is impregnated under vacuum, before impregnation the final product is thoroughly dried in vacuum chambers at elevated temperature (up to 130 ° C). The residual pressure during impregnation and drying ensures the elimination of voids in the paper and almost complete degassing of the oil. The air that remains in the oil is less than one hundredth of the amount of air dissolved in the oil at equilibrium under normal conditions (solubility of air in oil), equal to 10-11% by volume.

Oil-paper insulation has a very high short-term strength Epr, equal to 50 - 120 kV / mm at alternating voltage and 100 - 250 kV / mm at direct voltage, and therefore it is used in structures with high electric field strength.

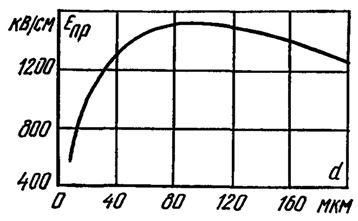

The electrical strength of oil paper insulation depends on the number of layers of paper. For sheet insulation made of capacitor paper, initially, as the number of layers increases, the strength increases, due to the fact that the probability of coincidence of weak, defective places in the sheet decreases, and then decreases, as the heat dissipation worsens and the possibility of thermal breakdown arises, and the effect of field inhomogeneity at the edges of the electrodes also increases. The maximum breaking stress is observed at 6-10 layers of paper (Fig. 2).

Rice. 2.Dependence of the breaking strength of 10 micron paper on the thickness of the insulation

The insulation strength of cable paper in homogeneous and slightly inhomogeneous fields is determined by the maximum field strength and depends a little on the thickness d... In highly inhomogeneous fields, for example, at the sharp edge of the electrode, the breakdown strength decreases with increasing insulation thickness.

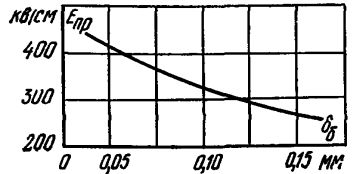

Under alternating voltage, the breakdown of a paper-oil multilayer dielectric always begins with partial breakdowns of the oil layers. Therefore, when designing insulation, they tend to make the oil layers thinner, because with thin layers the breakdown voltage in the oil increases. This is achieved by increasing the winding density, crimping and above all by reducing the thickness of the paper. The use of thin paper leads to a noticeable increase in the dielectric strength of the insulation (Fig. 3).

Rice. 3. Dependence of breaking strength on paper thickness at power frequency

Increasing the density of the paper leads to an increase in the dielectric strength of the paper sheets. Therefore, the short-term strength of oil paper insulation increases with the density of the paper, but at the same time the stress in the oil increases, leading to a reduction in strength and a reduction in the service life of the insulation under sustained stress effects that are associated with partial discharges in the oil layers.

The short-term and long-term strength of oil paper insulation increases significantly with increasing pressure.As the pressure increases, the strength of the oil in the interlayers increases and, moreover, the development of a discharge in the air inclusions becomes more difficult.

A noticeable decrease in the short-term and long-term electrical strength of paper-oil insulation is observed when wetting. Moisture is especially strong at elevated temperatures.

The strength of oil paper insulation pulses increases with decreasing pulse duration. The influence of paper density, thickness and number of paper layers on the impulse strength of oil paper insulation is the same as that of power frequency voltage. Increasing the pressure, however, significantly increases the breakdown voltage for standard aperiodic pulses.

The short-term strength of the paper-oil insulation during the development of a layer discharge is 2-3 times less than at field voltages normal to the surface of a solid dielectric.

Other liquids can be used instead of oil for impregnating paper. Chlorinated biphenyls are used to impregnate capacitors. Polychlorinated biphenyls (sovol, sovtol) and special impregnating mixtures based on them are compatible with paper, have an increased dielectric constant and sufficiently high dielectric strength. At an industrial frequency, the field between the layers of paper and the liquid in this case is distributed more evenly than in similar structures of oil-impregnated insulation. The main limitations in using chlorinated liquids are related to their high toxicity.

For impregnation cable insulation synthetic liquid hydrocarbons (octol, dodecbenzene, etc.) are also used.In addition, synthetic films or composite paper film insulation impregnated with oil or other insulating liquids are used instead of paper in cables and capacitors. In such systems, the paper plays the role of a wick that draws the impregnating mass into the depth of the insulation. Impregnation of pure polymer films is difficult due to their poor wettability.