What is synchronous rotation

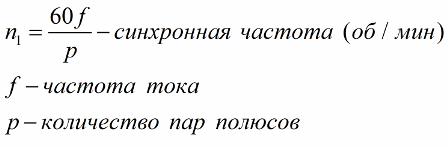

The rotor speed at which it operates asynchronous engine, depends on the frequency of the supply voltage, the power of the current load on the shaft and the number of electromagnetic poles of the given motor. This real speed (or operating frequency) is always less than the so-called synchronous frequency, which is determined only by the parameters of the power source and the number of poles of the stator winding of this asynchronous motor.

Therefore, the synchronous speed of the motorI am Whether the rotation frequency of the magnetic field of the stator winding is at the nominal frequency of the supply voltage and differs slightly from the operating frequency. As a result, the number of revolutions per minute under load is always less than the so-called synchronous revolutions.

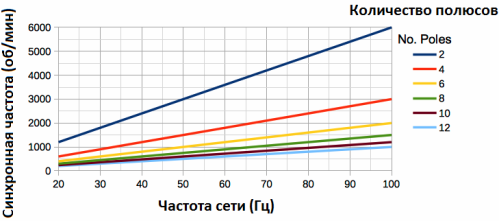

The figure shows how the frequency of synchronous rotation for an induction motor with one or another number of stator poles depends on the frequency of the supply voltage: the higher the frequency, the greater the angular speed of rotation of the magnetic field. For example, in variable frequency drives changing the frequency of the supply voltage changing the synchronous frequency of the motor. This also changes the operating speed of the motor rotor under load.

Typically, the stator winding of an induction motor is supplied with three-phase alternating current, which creates a rotating magnetic field. And the more pairs of poles — the lower the frequency of synchronous rotation — the frequency of rotation of the magnetic field of the stator.

Most modern asynchronous motors have from 1 to 3 pairs of magnetic poles, in rare cases 4, because the more poles, the lower the efficiency of the asynchronous motor. However, with fewer poles, the rotor speed can be changed very, very smoothly by changing the frequency of the supply voltage.

As noted above, the actual operating frequency of an induction motor differs from its synchronous frequency. Why is it happening? When the rotor rotates at a frequency lower than synchronous, then the rotor wires cross the stator magnetic field at a certain speed and an EMF is induced in them. This EMF creates currents in the closed rotor conductors, as a result of which these currents interact with the rotating magnetic field of the stator and a torque occurs - the rotor is pulled by the magnetic field of the stator.

If the torque has a sufficient value to overcome the frictional forces, then the rotor starts to rotate until the electromagnetic torque is equal to the braking torque that is created by the load, frictional forces, etc.

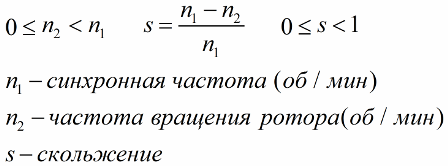

In this case, the rotor lags behind the stator magnetic field all the time, the operating frequency cannot reach the synchronous frequency, because if this happens, then the EMF will cease to be induced in the rotor wires and the torque will simply not appear. As a result, for the motor mode the value "slip" (slip s, as a rule, it is 2-8%), in connection with which the following inequality of the engine is also true:

But if the rotor of the same asynchronous motor is rotated with the help of some external drive, for example, an internal combustion engine, to such a speed that the speed of the rotor exceeds the synchronous frequency, then the emf in the rotor wires and the active current in them will acquire a certain direction and induction motor will become generator.

The total electromagnetic moment turns out to be retarded, the slip s becomes negative. But for the generator mode to manifest, it is necessary to supply the induction motor with reactive power, which would create a magnetic field on the stator. At the time of starting such a machine in generator mode, the residual induction of the rotor and the capacitors which are connected to the three phases of the stator winding supplying the active load may be sufficient.