Electromagnetic devices: purpose, types, requirements, design

Purpose of electromagnetic devices

The production, transformation, transmission, distribution or consumption of electrical energy is carried out using electrical devices. From all their variety, we single out electromagnetic devices, the work of which is based about the phenomenon of electromagnetic inductionaccompanied by the appearance of magnetic fluxes.

Static electromagnetic devices include chokes, magnetic amplifiers, transformers, relays, starters, contactors and other devices. Rotating — electric motors and generators, electromagnetic clutches.

A set of ferromagnetic parts of electromagnetic devices designed to conduct the main part of the magnetic flux, Named magnetic system of an electromagnetic device… A special structural unit of such a system is magnetic circuit… Magnetic fluxes passing through magnetic circuits can be partially confined in a non-magnetic medium, forming stray magnetic fluxes.

Magnetic fluxes passing through a magnetic circuit can be created using direct or alternating electric currents flowing in one or more inductive coils… Such a coil is an electrical circuit element designed to use its own inductance and/or its own magnetic field.

One or more coils are formed liquidation… The part of the magnetic circuit on which or around which the coil is located is called core, is called the part on which or around which the coil is not located yoke.

The calculation of the main electrical parameters of electromagnetic devices is based on the law of total current and the law of electromagnetic induction. The phenomenon of mutual induction is used to transfer energy from one electrical circuit to another.

See more details here: Magnetic circuits of electrical devices and here: What is the magnetic circuit calculation for?

Requirements for magnetic circuits of electromagnetic devices

The requirements for magnetic cores depend on the functional purpose of the electromagnetic devices in which they are used.

In electromagnetic devices, both constant and/or alternating magnetic fluxes can be used. Permanent magnetic flux causes no energy losses in magnetic circuits.

Magnetic cores operating under exposure conditions constant magnetic flux (eg beds for DC machines) can be made from cast blanks with subsequent machining. With a complex configuration of magnetic circuits, it is more economical to manufacture them from several elements.

The passage through the magnetic circuits of an alternating magnetic flux is accompanied by energy losses, which are called magnetic losses… They cause the magnetic circuits to heat up. It is possible to reduce the heating of the magnetic cores by special measures for their cooling (for example, working in oil). Such solutions complicate their design, increase the costs of their production and operation.

Magnetic losses consist of:

-

loss of hysteresis;

-

eddy current losses;

-

additional losses.

Hysteresis losses can be reduced by using soft magnet ferromagnets with a narrow hysteresis loop.

Eddy current losses are usually reduced by:

-

use of materials with lower specific electrical conductivity;

-

the production of magnetic cores from electrically insulated strips or plates.

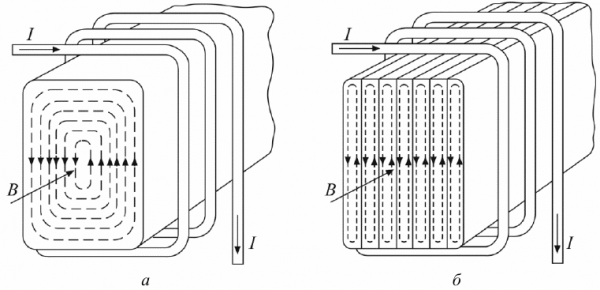

Distribution of eddy currents in different magnetic circuits: a — in casting; b — in a set of parts made of sheet materials.

The middle part of the magnetic circuit is to a greater extent covered by eddy currents compared to its surface, which leads to a «displacement» of the main magnetic flux towards the surface of the magnetic circuit, that is, a surface effect occurs.

This leads to the fact that at a certain frequency characteristic of the material of this magnetic circuit, the magnetic flux will be completely concentrated in a thin surface layer of the magnetic circuit, the thickness of which is determined by the penetration depth at a given frequency.

The presence of eddy currents flowing in a magnetic core made of a material with low electrical resistance leads to corresponding losses (eddy current losses).

The task of reducing eddy current losses and maximally preserving the magnetic flux is solved by manufacturing magnetic circuits from individual parts (or their parts), which are electrically isolated from each other. In this case, the cross-sectional area of the magnetic circuit remains unchanged.

Plates or strips stamped from sheet materials and wound on a core are widely used. Different technological methods can be used to insulate the surfaces of plates (or strips), of which the application of insulating varnishes or enamels is most often applied.

A magnetic circuit made of separate parts (or their parts) allows:

-

reduction of eddy current losses due to the perpendicular arrangement of the plates relative to the direction of their circulation (in this case, the length of the circuits along which eddy currents can circulate decreases);

-

to obtain a negligible non-uniform distribution of the magnetic flux, since at a small thickness of the sheet material, commensurate with the penetration depth, the shielding effect of the eddy currents is small.

Other requirements can be imposed on the materials of the magnetic cores: temperature and vibration resistance, low cost, etc. When designing a specific device, the soft magnetic material whose parameters best meet the specified requirements is selected.

Design of magnetic cores

Depending on the production technology, the magnetic cores of electromagnetic devices can be divided into 3 main groups:

-

lamellar;

-

tape;

-

molded.

Lamellar magnetic circuits are recruited from separate, electrically isolated plates from each other, which makes it possible to reduce eddy current losses. Tape magnetic cores are obtained by winding a tape of a certain thickness. In such magnetic circuits, the effect of eddy currents is significantly reduced, since the strip planes are covered with an insulating varnish.

The formed magnetic cores are produced by casting (electrical steel), ceramic technology (ferrites), mixing of components followed by pressing (magneto-dielectrics) and other methods.

In the manufacture of the magnetic circuit of an electromagnetic device, it is necessary to ensure its specific design, which is determined by many factors (device power, operating frequency, etc.), including the presence or absence of direct or reverse conversion of electromagnetic energy into mechanical energy in the device.

The designs of devices in which such a transformation occurs (electric motors, generators, relays, etc.) include parts that move under the influence of electromagnetic interaction.

Devices in which electromagnetic induction does not cause the conversion of electromagnetic energy into mechanical energy (transformers, chokes, magnetic amplifiers, etc.) are called static electromagnetic devices.

In static electromagnetic devices, depending on the design, armored, rod and ring magnetic circuits are most often used.

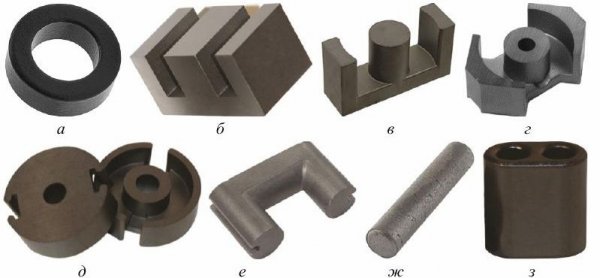

Molded magnetic cores can have a more complex design than sheets and strips.

Formed magnetic cores: a — round; b — d — armored; d — cup; f, g — rotation; h — many openings

Armored magnetic cores are distinguished by their simplicity of design and, as a result, manufacturability. In addition, this design provides better (compared to others) coil protection from mechanical influences and electromagnetic interference.

Core magnetic circuits are different:

-

good cooling;

-

low sensitivity to disturbances (since the EMF of disturbances induced in neighboring coils is opposite in sign and is partially or completely compensated);

-

less (relative to the armor) weight with the same power;

-

less (relative to armor) dissipation of magnetic flux.

The disadvantages of devices based on rod magnetic circuits (relative to devices based on armored ones) include the laboriousness of manufacturing coils (especially when they are placed on different rods) and their weaker protection from mechanical influences.

Due to the low leakage currents, ring magnetic circuits are distinguished, on the one hand, by good noise isolation, and on the other hand, by a small effect on nearby elements of electronic equipment (REE). For this reason, they are widely used in radio engineering products.

The disadvantages of circular magnetic circuits are associated with their low technology (difficulties in winding the coils and installing electromagnetic devices at the place of use) and limited power — up to hundreds of watts (the latter is explained by the heating of the magnetic circuit, which has no direct cooling due to the located on it turns of the coil).

The choice of the type and type of the magnetic circuit is made taking into account the possibility of obtaining the smallest values of its mass, volume and cost.

Sufficiently complex structures have magnetic circuits of devices in which there is a direct or reverse conversion of electromagnetic energy into mechanical energy (for example, magnetic circuits of rotating electrical machines). Such devices use molded or plate magnetic circuits.

Types of electromagnetic devices

Throttle — a device used as an inductive resistance in alternating or pulsating current circuits.

Magnetic cores with a non-magnetic gap are used in AC chokes that are used for energy storage and in smoothing chokes designed to smooth out rectified current ripple. At the same time, there are chokes in which the size of the non-magnetic gap can be adjusted, which is necessary to change the inductance of the choke during its operation.

The device and principle of operation of the electric throttle

Magnetic amplifier — a device consisting of one or more magnetic circuits with coils by means of which the current or voltage can be changed in magnitude in an electrical circuit supplied by an alternating voltage or alternating current source, based on the use of the phenomenon of saturation of ferromagnet under the action of a permanent bias field.

The principle of operation of the magnetic amplifier is based on a change in the differential magnetic permeability (measured on an alternating current) with a change in the direct bias current, therefore the simplest magnetic amplifier is a saturated choke containing a working coil and a control coil.

Transformer is called a static electromagnetic device that has two (or more) inductively coupled coils and is designed to convert by electromagnetic induction one or more AC systems into one or more other AC systems.

The power of the transformer is determined by the maximum possible induction of the magnetic core material and its dimensions. Therefore, the magnetic cores (usually of the rod type) of powerful power transformers are assembled from sheets of electrical steel with a thickness of 0.35 or 0.5 mm.

The device and principle of operation of the transformer

Electromagnetic relay is called an electromechanical relay, the operation of which is based on the effect of a magnetic field of a stationary coil on a moving ferromagnetic element.

Any electromagnetic relay contains two electrical circuits: an input (control) signal circuit and an output (controlled) signal circuit. According to the device principle of the controlled circuit, non-polarized and polarized relays are distinguished. The operation of non-polarized relays, unlike polarized relays, does not depend on the direction of the current in the control circuit.

How an electromagnetic relay works and works

Differences between DC and AC electromagnetic relays

Rotating electric machine — a device designed to convert energy based on electromagnetic induction and the interaction of a magnetic field with an electric current, containing at least two parts involved in the main conversion process and capable of rotating or rotating relative to each other.

The part of electrical machines that includes a stationary magnetic circuit with a coil is called the stator, and the rotating part is called the rotor.

An electrical machine designed to convert mechanical energy into electrical energy is called an electrical machine generator. An electric machine designed to convert electrical energy into mechanical energy is called a rotary electric motor.

The principle of operation and the device of electric motors

The principle of operation and the device of generators

The above examples of using soft materials to create electromagnetic devices are not exhaustive. All these principles also apply to the design of magnetic circuits and other electrical products that use inductors, such as electrical switching devices, magnetic locks, etc.