The principle of operation of the frequency converter and the criteria for its selection for the user

A brief description of the purpose, principle of operation and criteria for selecting a frequency converter as a control device for an asynchronous electric motor.

A brief description of the purpose, principle of operation and criteria for selecting a frequency converter as a control device for an asynchronous electric motor.

Squirrel cage induction motor today it is the most massive and reliable device for controlling various machines and mechanisms. But every medal has a flip side.

The two main disadvantages of the induction motor are the impossibility of simple rotor speed control, very large starting current — five, seven times the nominal. If only mechanical control devices are used, these disadvantages lead to large energy losses and shock mechanical loads. This has an extremely negative effect on the service life of the equipment.

Frequency converter

Frequency converter with pulse width control (PE with PWM) reduces inrush currents by 4-5 times. It provides a smooth start of the induction motor and controls the drive according to a given voltage / frequency ratio.

The frequency converter provides energy savings of up to 50%. It becomes possible to allow feedback between neighboring devices, i.e. self-adjusting equipment for the task and changing the operating conditions of the entire system.

The principle of operation of the frequency converter

The PWM frequency converter is double conversion inverter… First the mains voltage 220 or 380 V is rectified by the input diode bridge, then it is smoothed and filtered using capacitors.

This is the first stage of transformation. At the second stage, from constant voltage, using control microcircuits and an output bridge IGBT switches, a PWM sequence with a certain frequency and duty cycle is formed. At the output of the frequency converter, packets of rectangular pulses are issued, but due to the inductance of the stator windings of the induction motor, they are integrated and finally turn into a voltage close to a sinusoid.

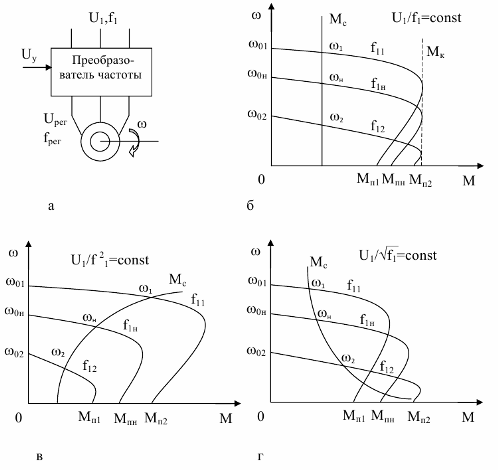

Mechanical characteristics of an asynchronous electric motor with frequency regulation of speed: a — connection diagram; b — characteristics for a load with a constant static moment of resistance; c — fan load characteristics; d — static load torque characteristics, inversely proportional to the angular speed of rotation.

Mechanical characteristics of an asynchronous electric motor with frequency regulation of speed: a — connection diagram; b — characteristics for a load with a constant static moment of resistance; c — fan load characteristics; d — static load torque characteristics, inversely proportional to the angular speed of rotation.

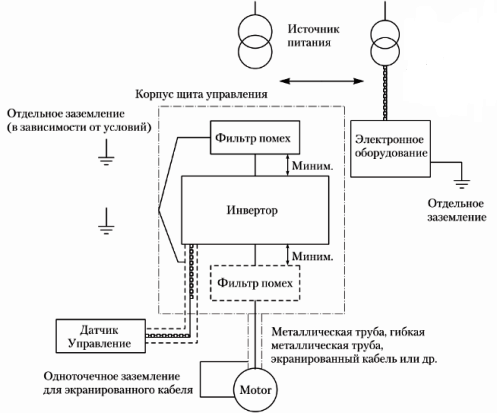

A typical circuit for switching on a frequency converter

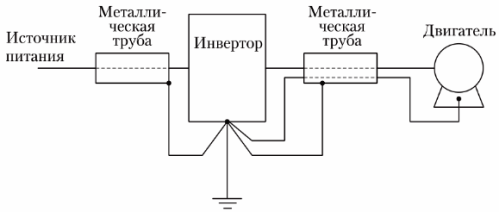

A typical circuit for switching on a frequency converter  An example of connecting power lines (cables) in a frequency converter circuit

An example of connecting power lines (cables) in a frequency converter circuit

Criteria for selecting frequency converters

By the method of control

Immediately discard those converters that are not suitable in terms of power, performance type, overload capacity, etc. According to the type of management you have to decide what to choose, scalar or vector control.

Most modern frequency converters implement vector control, but such frequency converters are more expensive than scalar frequency converters.

Vector control allows more precise control by reducing static error. Scalar mode only supports a constant ratio between the output voltage and the output frequency, but for fans, for example, this is quite sufficient.

Since its inception, vector control has become an extremely popular control strategy for induction motors. Currently, most frequency converters implement vector control or even sensorless vector control (this trend is found in frequency converters that originally implement scalar control and do not have terminals for connecting a speed sensor).

The basic principle of vector control consists in separate independent regulation of the magnetizing current of the motor and the quadrature current, to which the mechanical torque of the shaft is proportional. The magnetizing current determines the value of the rotor zero flux linkage and is kept constant.

When the speed stabilizes, the quadrature current setpoint is generated using a separate PI controller whose input is the discrepancy between the desired and measured motor speed. Thus, the quadrature current is always set to the minimum level so as to provide sufficient mechanical torque to maintain the set speed. Therefore, vector control has high energy efficiency.

Through power

If the power of the equipment is approximately the same, then choose converters from the same company with a capacity according to the power of the maximum load. This will ensure interchangeability and simplify equipment maintenance. It is recommended that the service center of the selected frequency converter is in your city.

Via mains voltage

Always choose a converter with the widest possible voltage range, both down and up. The fact is that for local networks, the very word standard can only bring laughter through tears. If the low voltage will most likely cause the frequency converter to stop, then the increased voltage can cause the mains electrolytic capacitors to explode and the input of the device to fail.

By frequency adjustment range

By the number of control inputs

Discrete inputs are required to input control commands (start, stop, reverse, stop, etc.). Analog inputs are required for feedback signals (setting and setting of the drive during operation). Digital inputs are required to input high-frequency signals from digital speed and position sensors (encoders). The number of inputs can never be too large, but the more inputs, the more complex the system can be built and the more expensive it is.

By the number of output signals

Discrete outputs are used to output signals for various events (alarm, overheating, input voltage above or below level, error signal, etc.). Analog outputs are used to build complex feedback systems. Selection recommendations are similar to the previous paragraph.

Control bus

The equipment with which you will control the frequency converter must have the same bus and number of inputs / outputs as the selected frequency converter. Leave some space for inputs and outputs for future upgrades.

Under warranty

The warranty period indirectly allows you to evaluate the reliability of the frequency converter. Naturally, you should choose a frequency converter with a long-term plan.Some manufacturers specifically provide for cases of damage that are not covered by the warranty. Always read the documentation carefully and search online for reviews of equipment models and manufacturers. This will help you make the right choice. Do not spare money for quality service and staff training.

Frequency converter on the stand

Frequency converter on the stand

Overload capacity

As a first approximation, the power of the frequency converter should be selected 10-15% more than the motor power. The current of the converter should be higher than the rated current of the motor and slightly higher than the current of possible overloads.

In the description of a particular mechanism, the overload currents and the duration of their flow are usually indicated. Read the documentation! This will keep you entertained and possibly prevent equipment damage in the future. If the drive is also characterized by shock (peak) loads (loads for 2-3 seconds), then it is necessary to choose a converter for the peak current. Take 10% margin again.

See also on this topic: VLT AQUA Drive frequency converters for pump units