Electrical steel and its properties

Sheet electrical steel was most widely used in electrical engineering... This steel is an alloy of iron with silicon, the content of which is 0.8 - 4.8%. Such steels, which are introduced in a small amount of any substances to improve their properties, are called alloyed.

Sheet electrical steel was most widely used in electrical engineering... This steel is an alloy of iron with silicon, the content of which is 0.8 - 4.8%. Such steels, which are introduced in a small amount of any substances to improve their properties, are called alloyed.

Silicon is introduced into iron in the form of ferrosilicon (an alloy of iron cissilide FeSi with iron) and is in it in a dissolved state. Silicon reacts with the most harmful (for the magnetic properties of iron) impurity — oxygen, reducing iron from its oxides FeO and forms silicon dioxide SiO2, which partially passes into the slag.

Silicon also promotes the release of carbon from the compound Fe3C (cementite) with the formation of graphite. In this way, silicon eliminates the iron compounds (FeO and Fe3C) that cause an increase in coercive force and an increase in — loss of hysteresis… In addition, the presence of silicon in iron in an amount of 4% or more increases the electrical resistance compared to pure iron, resulting in losses of eddy currents.

Silicon also promotes the release of carbon from the compound Fe3C (cementite) with the formation of graphite. In this way, silicon eliminates the iron compounds (FeO and Fe3C) that cause an increase in coercive force and an increase in — loss of hysteresis… In addition, the presence of silicon in iron in an amount of 4% or more increases the electrical resistance compared to pure iron, resulting in losses of eddy currents.

Despite the fact that the saturation induction Bs of iron with an increase in silicon in it significantly increases and reaches a large value at 6.4% silicon (Bs = 2800 gauss), but still silicon is introduced no more than 4.8%. Increasing the silicon content by more than 4.8% leads to the fact that steels acquire increased brittleness, i.e. their mechanical properties deteriorate.

Electric steel is melted in marten furnaces. Sheets are produced by rolling a steel ingot in a cold or hot state. Therefore, distinguish between cold and hot rolled electrical steel.

Iron has a cubic crystal structure. According to the study of the magnetization, it turned out that it can be uneven in different directions of this cube. The crystal has the largest magnetization along the edge of the cube, the smallest along the diagonal of the face, and the smallest along the diagonal of the cube. Therefore, it is desirable that all iron crystals in the sheet are arranged in the course of rolling in rows in the direction of the edges of the cube.

Iron has a cubic crystal structure. According to the study of the magnetization, it turned out that it can be uneven in different directions of this cube. The crystal has the largest magnetization along the edge of the cube, the smallest along the diagonal of the face, and the smallest along the diagonal of the cube. Therefore, it is desirable that all iron crystals in the sheet are arranged in the course of rolling in rows in the direction of the edges of the cube.

This is achieved by repeatedly rolling steel sheets, with a strong reduction (up to 70%) and subsequent annealing in a hydrogen atmosphere. This promotes the purification of the steel from oxygen and carbon, as well as the expansion of the crystals and their orientation so that the edges of the crystals coincide with the direction of rolling. Such steels are called textured... They have higher magnetic properties in the rolling direction than conventional hot-rolled steel.

Textured steel sheets are produced by cold rolling. Magnetic permeability they are higher and the hysteresis losses are smaller than those of hot-rolled sheets.In addition, for cold-rolled steel, the induction in weak magnetic fields increases more strongly than for hot-rolled steel, i.e. the magnetization curve in weak fields is significantly higher than the curve for hot-rolled steel.

Rice. 1. Manufacturing process of electrical steel sheet

It should be noted, however, that as a result of the grain orientation of grain-oriented steel along the rolling direction, the magnetic permeability in other directions is lower than that of hot-rolled steel. So, with induction 6 = 1.0 T in the direction of rolling, the magnetic permeability μm = 50,000, and in the direction perpendicular to the rolling μm — 5500. In this connection, when assembling W-shaped transformer cores, separate steel strips are used , cut along the rolling length, which are then mixed so that the direction of the magnetic flux coincides with the rolling direction of the steel or makes an angle of 180 ° with it.

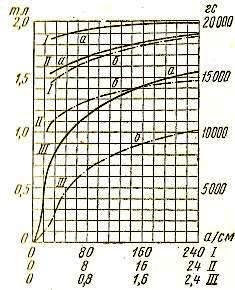

In fig. 2 shows the magnetization curves of electrical steel EZZOA and E41 for three ranges of magnetic field strength: 0 — 2.4, 0 — 24 and 0 — 240 A / cm.

Rice. 2. Magnetization curves of electrical steels: a — steel E330A (textured), b — steel E41 (without texture)

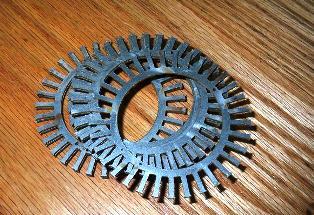

Electrical steel sheet has good magnetic characteristics—high saturation induction, low coercive force, and low hysteresis loss. Due to these properties, it is widely used in electrical engineering for the production of stator and rotor cores of electric machines, power transformer cores, current transformers and magnetic cores of various electrical devices.

Domestic electrical steel differs in its silicon content, in the way sheets are made, as well as in magnetic and electrical properties.

Letter D with the designation steel means «elektrotekhnikanichnaya steel», the first number after the letter (1, 2, 3 and 4) means the degree of alloying of steel with silicon, and the silicon content is within the following limits in%: for low-alloy steel (E1) from 0.8 to 1.8, for medium alloy steel (E2) from 1.8 to 2.8, for high alloy steel (EZ) from 2.8 to 3.8, for high alloy steel (E4) from 3.8 to 4.8.

Average electrical resistance to become ρ also depends on the amount of silicon. The higher, the higher the silicon content of the steel. Mirok E1 steels have resistance ρ =0.25 Ohm NS mm2/m, E2 grades — 0.40 Ohm NS mm2/m, EZ grades — 0.5 Ohm NS mm2/m and E4 grades — 0.6 Ohm NS mm2/ m.

NSmagnetization (W / kg). These losses are smaller, the higher the number, that is, the higher the degree of alloying of steel with silicon. Zeros after these numbers ОznAssume that the steel is cold rolled texture (0) and cold rolled low texture (00). The letter A indicates particularly low specific losses when reversing the magnetization of the steel.

Electrical steel is produced in the form of sheets with a width of 240 to 1000 mm, a length of 720 to 2000 mm and a thickness of 0.1, 0.2, 0.35, 0.5 and 1.0 mm. Textured steels are the most widely used, as they have the highest values of magnetic characteristics.

Rice. 3. Electrical steel