Load modes of power systems and optimal load distribution between power plants

The way energy is consumed and therefore the load on the systems is uneven: it has characteristic fluctuations within a day, as well as seasonal fluctuations within a year. These fluctuations are mainly determined by the rhythm of work of the enterprises — consumers of electricity, related to this rhythm of life of the population, to a lesser extent — by geographical factors.

In general, the daily cycle is always characterized by a greater or lesser reduction in consumption at night, for the annual cycle — in the summer months. The depth of these load fluctuations depends on the composition of users.

Enterprises that work around the clock, especially with a predominance of continuous technological processes (metallurgy, chemistry, coal mining industry), have almost the same mode of consumption.

Enterprises from the metalworking and machine-building industries, even with three-shift work, have noticeable fluctuations in energy consumption associated with the usual decrease in production activity during night shifts. When working in one or two shifts at night, a sharp decrease in energy consumption is observed. A noticeable decrease in consumption is also observed in the summer months.

Even sharper fluctuations in energy consumption are characteristic of food and light industry enterprises. The largest uneven consumption is observed in the household sector.

The load mode of the system reflects all these fluctuations in energy consumption in a summed and, of course, somewhat smoothed form. Load conditions are usually presented in the form of a load schedule.

On the daily graph, hours are plotted on the abscissa, and loads in MW or % of maximum load are plotted on the ordinate. The maximum load most often falls in the evening hours, when the lighting is superimposed on the production energy consumption. That is why the maximum point shifts somewhat within the year.

There is a load peak in the morning hours, reflecting maximum production activity. In the afternoon, the load decreases, at night it decreases sharply.

Months are plotted on the abscissa of annual charts, and monthly kilowatt-hour amounts or monthly peak loads are plotted on the ordinate. The maximum load falls at the end of the year — due to its natural increase during the year.

Uneven charging mode, on the one hand, the variety of energy production equipment and its operational and technical-economic characteristics, on the other hand, pose a complex task for the system staff for optimal load distribution between stations and generating units.

Power generation comes at a price. For thermal stations — these are fuel costs, in addition to the maintenance of service personnel, equipment repairs, depreciation deductions.

At different stations, depending on their technical level, power, equipment condition, the specific production cost of one Vt • h is different.

The general criterion for load distribution between stations (and within a station between blocks) is the minimum total operating costs for the production of a given amount of electricity.

For each station (each unit), costs can be presented in functional relation to the charging mode.

The condition for the minimum of the total costs and therefore the condition for the optimal distribution of loads in the system is formulated as follows: the load must be distributed so that the equality of the relative steps of the stations (units) is always maintained.

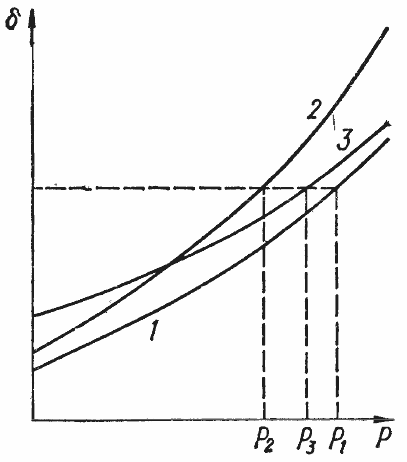

Almost relative steps of stations and units at different values of their loads are calculated in advance by dispatch services and are displayed as curves (see picture).

Relative growth curves

The horizontal line reflects the distribution of this load that corresponds to the optimal condition.

The optimal distribution of the system load between the stations also has a technical side.The units that cover the variable part of the load curve, especially the sharp upper peaks, are operated under rapidly changing load conditions, sometimes with daily stop-starts.

Modern powerful steam turbine units are not adapted to such a mode of operation: they take many hours to start, operation in a variable load mode, especially with frequent stops, leads to an increase in accidents and accelerated wear, and is also associated with an additional rather sensitive excessive consumption of fuel.

Therefore, in order to cover the "peaks" of the load in the systems, units of another type are used, which are technically and economically well adapted to a mode of operation with a sharp variable load.

They are ideal for this purpose hydroelectric plants: the start-up of the hydraulic unit and its full load require one to two minutes, are not associated with additional losses and are technically quite reliable.

Hydroelectric plants designed to cover peak loads are built with dramatically increased capacity: this reduces the capital investment by 1 kW, which makes it comparable to the specific investment in powerful thermal power plants and ensures a more complete use of water resources.

Since the possibilities of building hydroelectric power plants in many areas are limited, where the topography of the area allows to obtain high enough heads, pumped storage hydroelectric power plants (PSPP) are built to cover the load peaks.

The units of such a station are usually reversible: during system failure hours at night, they work as pumping units, raising water in a high-placed reservoir. During full load hours, they operate in electricity generation mode by energizing the water stored in the tank.

They are widely used to cover the load peaks of gas turbine power plants. Starting them up takes only 20-30 minutes, adjusting the load is simple and economical. The cost figures of peak GTPPs are also favorable.

Indicators of the quality of electrical energy are the degree of constancy of frequency and voltage. Maintaining a constant frequency and voltage at a given level is of great importance. As the frequency decreases, the speed of the motors decreases proportionally, therefore the performance of the mechanisms driven by them decreases.

It should not be thought that increasing the frequency and voltage has a beneficial effect. As the frequency and voltage increase, losses in magnetic circuits and coils of all electrical machines and devices increase sharply, their heating increases and wear accelerates. In addition, the change in the frequency and therefore in the number of revolutions of the engines often threatens to reject the product.

Frequency constancy is ensured by maintaining equality between the effective power of the primary motors of the system and the total opposing mechanical moment arising in the generators from the interaction of magnetic fluxes and currents. This torque is proportional to the electrical load of the system.

The load on the system changes constantly. If the load increases, the braking torque in the generators becomes greater than the effective torque of the main engines, there is a threat of speed reduction and frequency reduction. Reducing the load has the opposite effect.

To maintain the frequency, it is necessary to change the total effective power of the main engines accordingly: an increase in the first case, a decrease in the second. Therefore, in order to continuously maintain the frequency at a given level, the system must have a sufficient supply of extremely mobile standby power.

The task of frequency regulation is assigned to designated stations operating with a sufficient amount of free, rapidly mobilized power. Hydroelectric plants are best able to handle these responsibilities.

For more information on frequency control features and methods, see here: Frequency regulation in the power system