Diagram of the washing machine

The technological process of washing consists of feeding assemblies and parts into the washing chamber, lowering the curtain that closes the opening to prevent splashing of the cleaning solution, turning on the pump to supply the solution to the nozzles, ensuring the relative movement of parts and liquid jets. After the washing time has elapsed, the pump motor is switched off, the cover covering the inlet is lifted and the basket of parts is returned to its original position. Exhaust ventilation is used to remove vapors from the cleaning liquid during washing.

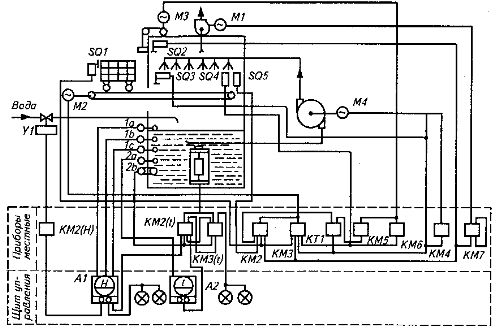

The washing process automation scheme is shown in figure 1.

Rice. 1. Scheme for automation of the washing process

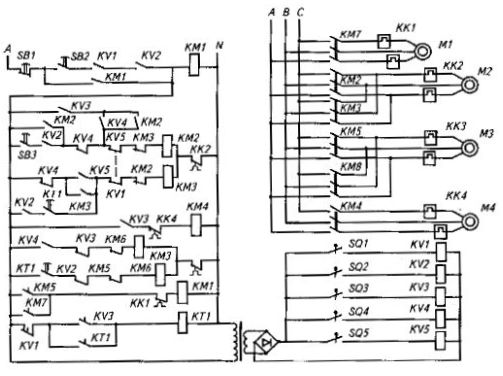

To control the drives of the washing machine, non-contact limit switches SQ1 — SQ5, complete with intermediate relays KV1 — KV5, are installed. In the initial state, the trolley is in the extreme left position (relay KV1 is on), the curtain is in the uppermost position (relay KV2 is on).

If these conditions are met and the SB2 button is pressed, the KM1 contactor turns on and blocks with its closing contact.When the SB3 button is pressed, voltage is applied to the winding of the KM2 carriage starter drive. When the carriage approaches the limit switch SQ4, the latter turns on the relay KV4, the opening contact of which disables the starter coil KM2, and the closing contact prepares the supply circuit of the starter coil KM2 along the KV3 — KV4 — KV5 — circuit KM3 and energizes the supply coil of the gate KM5.

Rice. 2. Scheme of the washing machine

Through the starter KM5, voltage is supplied to the coil of another starter-switch of the fan KM7. After lowering to its lowest position, the shutter, using the switch SQ3, turns on the relay KV3, which in turn turns on the pump starter KM1, the wash time relay KT1 and the carriage starter Vperyod. The carriage, continuing to move forward, acts on the switch SQ4.

Carriage movement continues until SQ5 is triggered. The relay disconnects power from the "Forward" relay coil and supplies it to the "Reverse" relay coil.

The movement of the carriage continues until the contacts of the time (wash) relay are actuated, which will ensure the actuation of the shutter drive starter «Up». It affects SQ3. In this case, the relay is turned off, the power supply from the pump starter is interrupted, and the supply circuit of the "Forward" carriage starter is interrupted. The second closing contact KT1 prepares the supply circuit of the back coil.

If the contacts of time relay KT1 are actuated, the carriage reaches SQ5 and returns back to SQ4.If the contacts of the relay KT1 close when the carriage moves «Back», then its movement continues, since its drive will receive power when the shutter is raised to the uppermost position along the circuit KV2 — KT1 — KV1 — KM2 — KV3, while the carriage always returns to the leftmost position, which makes SQ1 work. Relay KV1 disconnects power from starter KM3 and the carriage stops.

The same relay also turns off the time relay KT1. After replacing the cleaned parts in the cart with dirty ones and pressing the SB3 button, the entire process of feeding the parts carriage into the washing chamber and the cleaning process itself is repeated.

The extractor fan runs continuously. Turn it off by pressing the SB1 button.