Typical schemes for starting synchronous electric motors

Synchronous motors are widely used in industry for electric drives operating at constant speed (compressors, pumps, etc.). Recently, due to the advent of switching semiconductor technology, controlled synchronous electric drives have been developed.

The advantages of synchronous motors

A synchronous motor is a little more complicated than an asynchronous motor, but it has a number of advantages, which makes it possible to use it in some cases instead of an asynchronous one.

1. The main advantage of the synchronous electric motor is the ability to obtain an optimal mode for reactive energy, which is carried out by automatically adjusting the excitation current of the motor. A synchronous motor can operate without consuming or supplying reactive energy to the network, at a power factor (cos fi) equal to unity. If the enterprise needs to generate reactive power, then a synchronous motor operating with overexcitation can give it to the grid.

2.Synchronous motors are less sensitive to mains voltage fluctuations than asynchronous motors. Their maximum torque is proportional to the line voltage, while the critical torque of an induction motor is proportional to the square of the voltage.

3. Synchronous motors have high overload capacity. In addition, the overload capacity of a synchronous motor can be automatically increased by increasing the excitation current, for example, in the case of a sudden short-term increase in the load on the motor shaft.

4. The rotational speed of a synchronous motor remains unchanged for any shaft load within its overload capacity.

Methods of starting a synchronous motor

The following methods of starting a synchronous motor are possible: asynchronous start at full line voltage and starting at low voltage through a reactor or autotransformer.

The start of a synchronous motor is performed as an asynchronous start. The internal starting torque of a synchronous machine is small, while that of an implicit-pole machine is zero. To create an asynchronous torque, the rotor is equipped with a squirrel-cage starting cage, the bars of which are inserted into the slots of the pole system. (Of course, there are no rods between the poles in a salient-pole motor.) The same cell contributes to increasing the dynamic stability of the motor during load spikes.

Due to the asynchronous torque, the motor starts and accelerates. There is no excitation current in the rotor winding during acceleration.The machine is started unexcited, since the presence of excited poles would complicate the acceleration process, creating a braking torque similar to that of an induction motor during dynamic braking.

When the so-called Subsynchronous speed, which differs from synchronous by 3 - 5%, current is supplied to the excitation coil and the motor, after several oscillations around the equilibrium position, is attracted to synchronism. Exposed-pole motors, because of the reactive torque at low shaft torques, are sometimes brought into synchronism without supplying current to the field coil.

In synchronous motors, it is difficult to simultaneously provide the required values of the starting torque and the input torque, which is understood as the asynchronous torque developed when the speed reaches 95% of the synchronous speed. In accordance with the nature of the dependence of static torque on speed, i.e. in accordance with the type of mechanism for which the motor is designed, the parameters of the starting cell must be changed in the electric machine manufacturing plants.

Sometimes, in order to limit the currents when starting powerful motors, the voltage at the stator terminals is reduced, including in series the windings of the autotransformer or resistors. It should be borne in mind that when a synchronous motor is started, the circuit of the excitation winding is closed to a large resistance, exceeding the resistance of the winding itself by 5-10 times.

Otherwise, under the action of the currents induced in the winding during start-up, a pulsating magnetic flux occurs, the reverse component of which, interacting with the stator currents, creates a braking torque.This torque reaches its maximum value at a speed slightly above half of the nominal one, and under its influence the engine can stop acceleration at this speed. Leaving the field circuit open during starting is dangerous because the winding insulation can be damaged by the EMF induced in it.

Educational Filmstrip - "Synchronous Motors" produced by the Educational Materials Factory in 1966. You can watch it here: Filmstrip «Synchronous Motor»

Asynchronous start of a synchronous electric motor

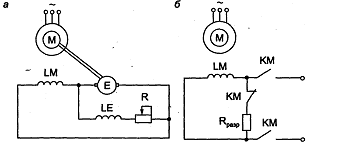

The excitation circuit of a synchronous motor with a blindly connected exciter is quite simple and can be used if the inrush currents do not cause a voltage drop in the network more than the permissible and statistical torque Ms <0.4 Mnom.

The asynchronous start of a synchronous motor is carried out by connecting the stator to the network. The motor is accelerated as an induction motor to a rotational speed close to synchronous.

In the process of asynchronous starting, the excitation winding is closed to the discharge resistance to avoid the destruction of the excitation winding during starting, since at low rotor speed significant overvoltages can occur in it. At a rotational speed close to synchronous, the contactor KM is triggered (the supply circuit of the contactor is not shown in the diagram), the excitation coil is disconnected from the discharge resistance and connected to the armature of the exciter. The beginning ends.

Typical Units of Synchronous Motor Excitation Circuits Using Thyristor Exciters to Start Synchronous Motors

Typical Units of Synchronous Motor Excitation Circuits Using Thyristor Exciters to Start Synchronous Motors

The weakness of most electric drives with synchronous motors, which greatly complicates the operation and increases the cost, has been the exciter of electric machines for many years. These days they are widely used to excite synchronous motors. thyristor exciters… They are supplied as a set.

Thyristor exciters of synchronous electric motors are more reliable and have higher efficiency. compared to electric machine exciters. With their help, questions about the optimal regulation of the excitation current to maintain constancy are easily solved. cos phi, the voltage of the busbars from which the synchronous motor is supplied, as well as limiting the rotor and stator current of the synchronous motor in emergency modes.

Thyristor exciters are equipped with most large synchronous electric motors manufactured. They usually perform the following functions:

- starting a synchronous motor with a starting resistor included in the field winding circuit,

- contactless shutdown of the starting resistor after the end of the start of the synchronous motor and its protection from overheating,

- automatic supply of excitation at the appropriate moment of starting the synchronous electric motor,

- automatic and manual adjustment of excitation current

- necessary forced excitation in case of deep voltage drops on the stator and sharp load jumps on the shaft of a synchronous motor,

- quick extinguishing of the field of a synchronous motor when it is necessary to reduce the field current and turn off the electric motor,

- protection of the rotor of a synchronous motor against continuous overcurrent and short circuits.

If the synchronous electric motor is started at reduced voltage, then at a «light» start it is excited until the stator winding turns on at full voltage, and at a «heavy» start the excitation is supplied at full voltage in the stator circuit. It is possible to connect the motor field winding to the armature of the exciter in series with the discharge resistance.

The process of supplying excitation to a synchronous motor is automated in two ways: as a function of speed and as a function of current.

The excitation system and control device for synchronous motors must provide:

- starting, synchronizing and stopping the engine (with automatic excitation at the end of the start);

- forced excitation with a factor of not less than 1.4 when the mains voltage drops to 0.8Un;

- the possibility of compensating by the engine the reactive power consumed (given) by adjacent electric receivers within the thermal capabilities of the engine;

- stopping the engine in case of failure in the excitation system;

- stabilization of the excitation current with an accuracy of 5% of the set value when the mains voltage changes from 0.8 to 1.1;

- regulation of excitation by deviation of the stator voltage with a dead zone of 8%;

- when the supply voltage of the stator of the synchronous motor changes from 8 to 20%, the current changes from the set value to 1.4 In, increasing the excitation current to ensure maximum motor overload.

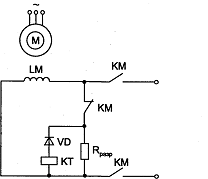

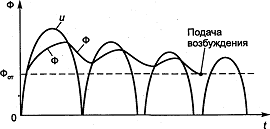

In the diagram shown in the figure, the excitation is supplied to a synchronous motor using a DC electromagnetic relay KT (Sleeving Time Relay).The relay coil is connected to the discharge resistance Rdisc through the VD diode. When the stator winding is connected to the mains, an emf is induced in the motor excitation winding. Direct current flows through the coil of the KT relay, the amplitude and frequency of the pulses of which depend on the slip.

Excitation supply to a synchronous motor depending on the speed

Excitation supply to a synchronous motor depending on the speed

At start-up, slip S = 1. As the motor accelerates, it decreases and the intervals between the corrected half-waves of the current increase; the magnetic flux gradually decreases along the curve Ф (t).

At a speed close to synchronous, the magnetic flux of the relay manages to reach the value of the relay dropout flux Fot at the moment when the current does not pass through the KT relay. The relay loses power and through its contact creates a power circuit of the KM contactor (the power circuit of the KM contactor is not shown in the diagram).

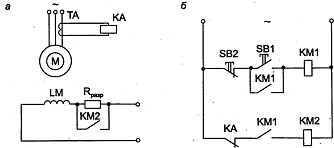

Consider the control of the power supply in the current function using a current relay. With the starting current, the current relay KA is activated and opens its contact in the circuit of the contactor KM2.

Graph of current and magnetic flux changes in time relay KT

Monitoring the excitation of a synchronous motor as a function of current

Monitoring the excitation of a synchronous motor as a function of current

At a speed close to synchronous, the KA relay disappears and closes its contact in the KM2 contactor circuit. Contactor KM2 activates, closes its contact in the machine excitation circuit and shunts resistor Rres.

See also: Selection of equipment for starting synchronous motors